custom printed corrugated folding cartons single wall packaging mailer boxes with logo PEP insert for camera home appliances

Description

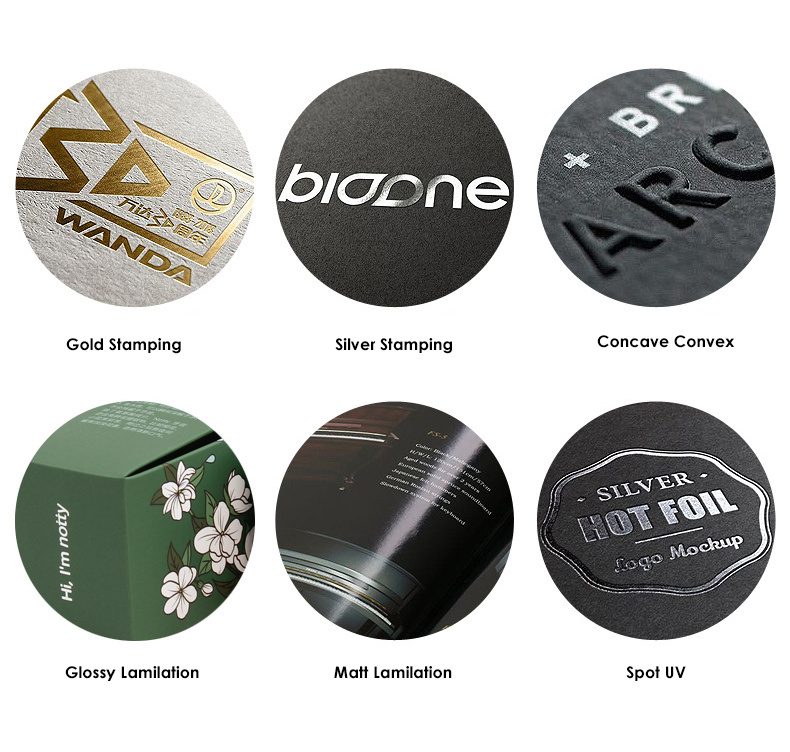

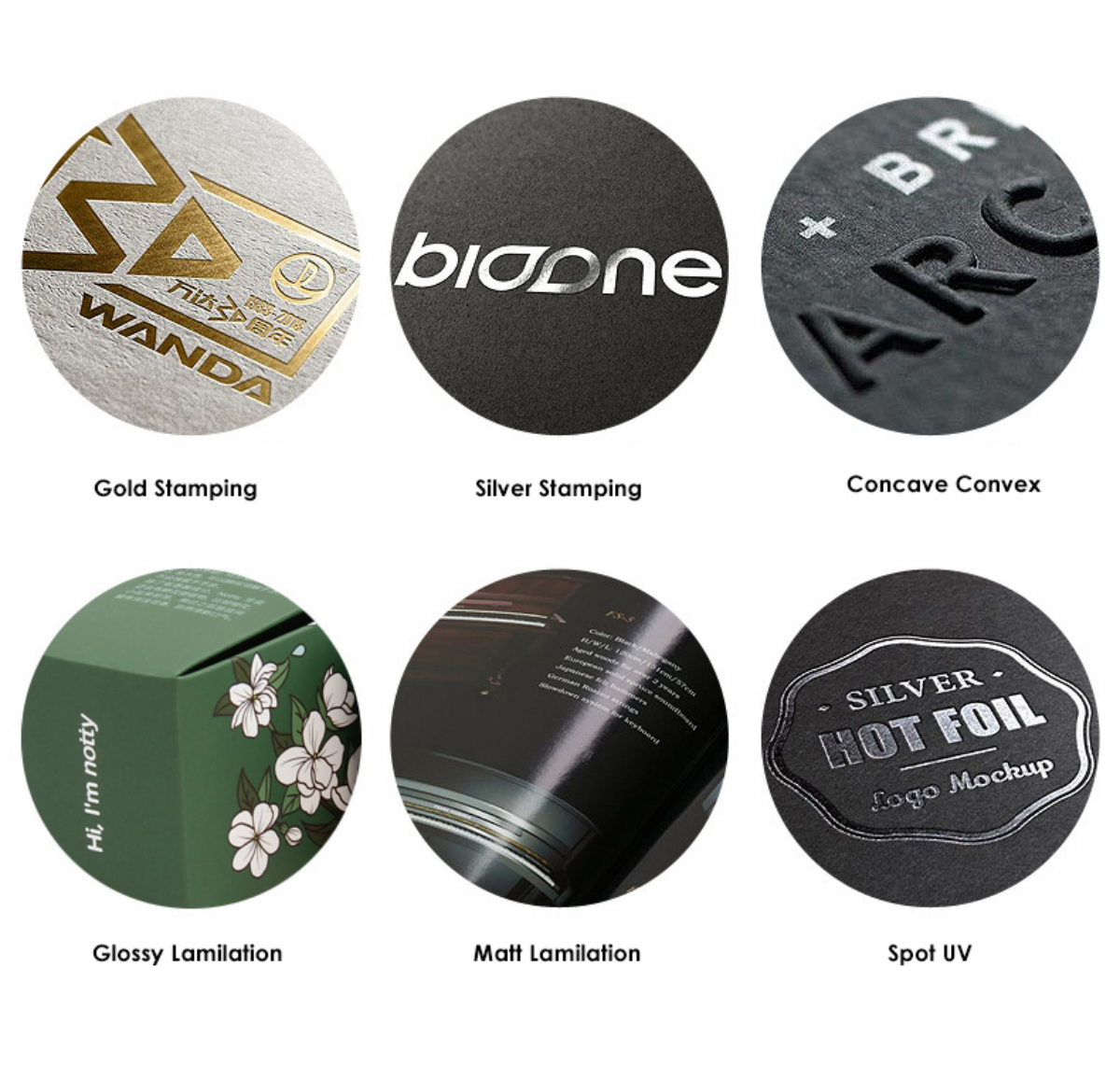

This is a 3 layers corrugated paper box, with white EPE inner tray. Tuck top lid, self lock bottom. Box dimensions and printing are customized. Surface treatment such as glossy lamination, spot UV both can be done.

Basic Info.

| Product Name | CCTV camera packaging box | Surface Treatment | Matte Lamination, etc. |

| Box Style | Product box | Logo Printing | Customized Logo |

| Material Structure | Corrugated board | Origin | Ningbo city, China |

| Weight | 32ECT, 44ECT, etc. | Sample type | Printing sample, or no print. |

| Shape | Rectangle | Sample Lead Time | 2-5 working days |

| Color | CMYK, Pantone color | Production Lead Time | 12-15 natural days |

| Printing mode | Offset Printing | Transport Package | Standard export carton |

| Type | One-sided Printing Box | MOQ | 2,000PCS |

Detailed Images

These details are used to show the quality, such as materials, printing and surface treatment.

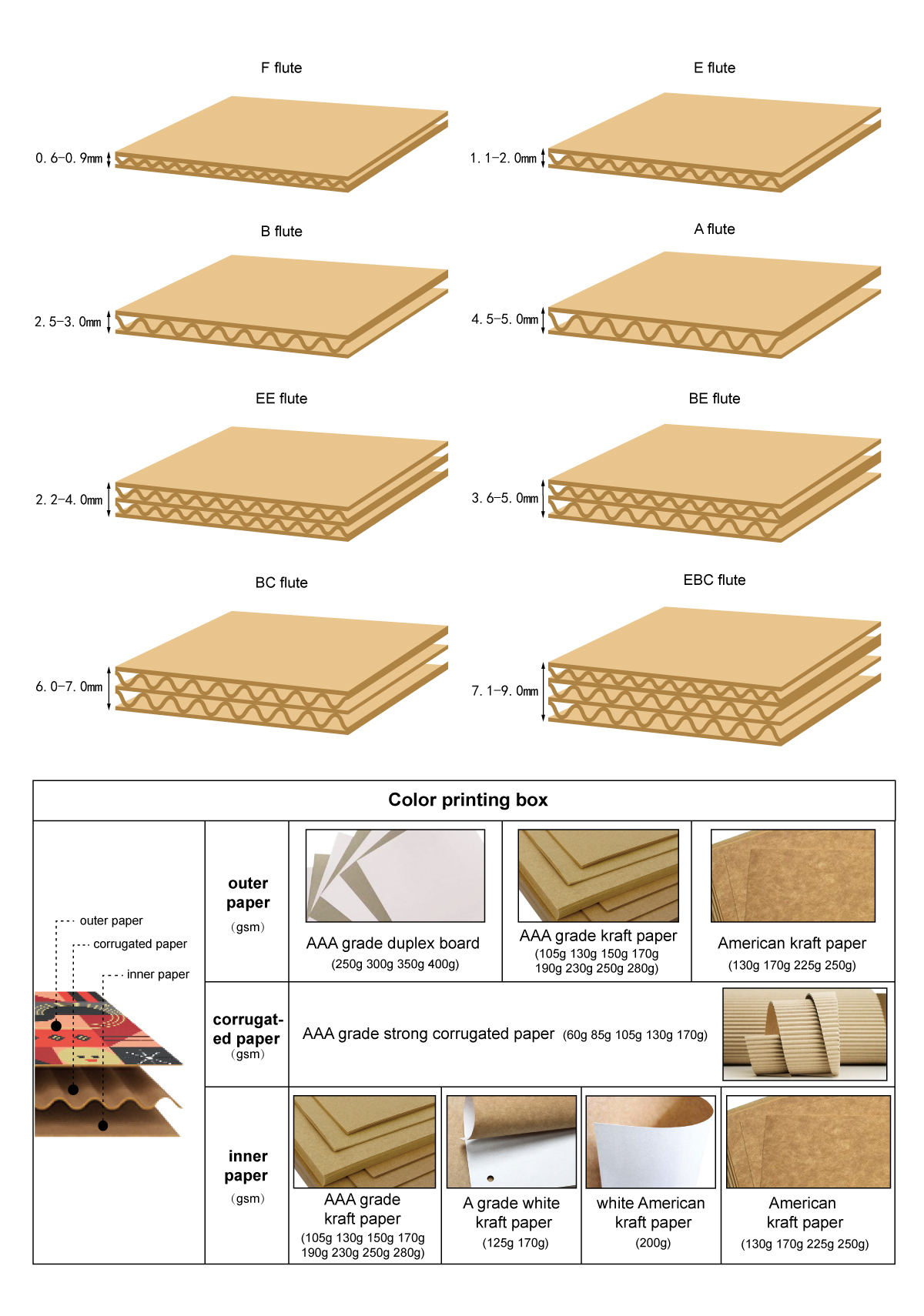

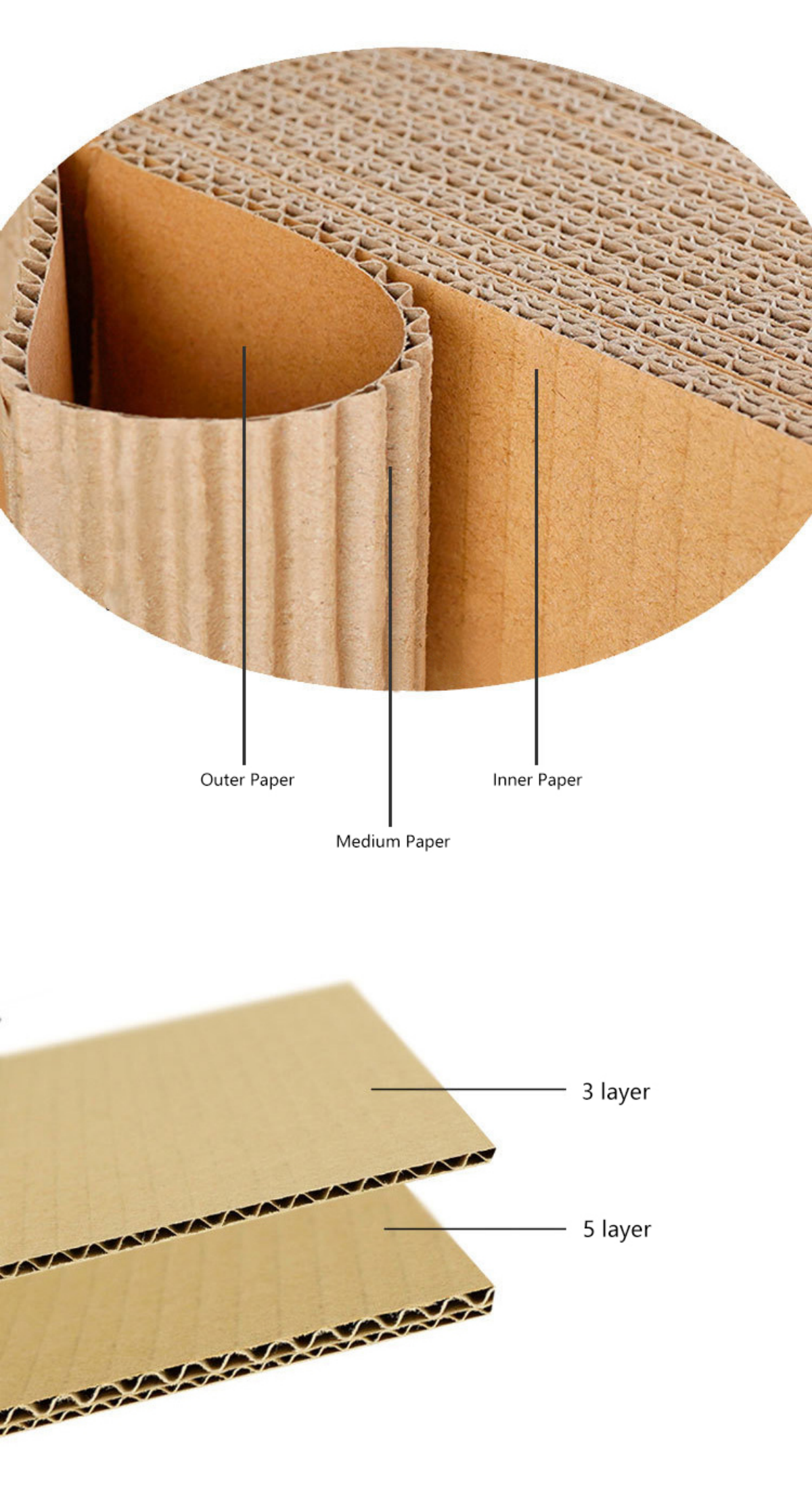

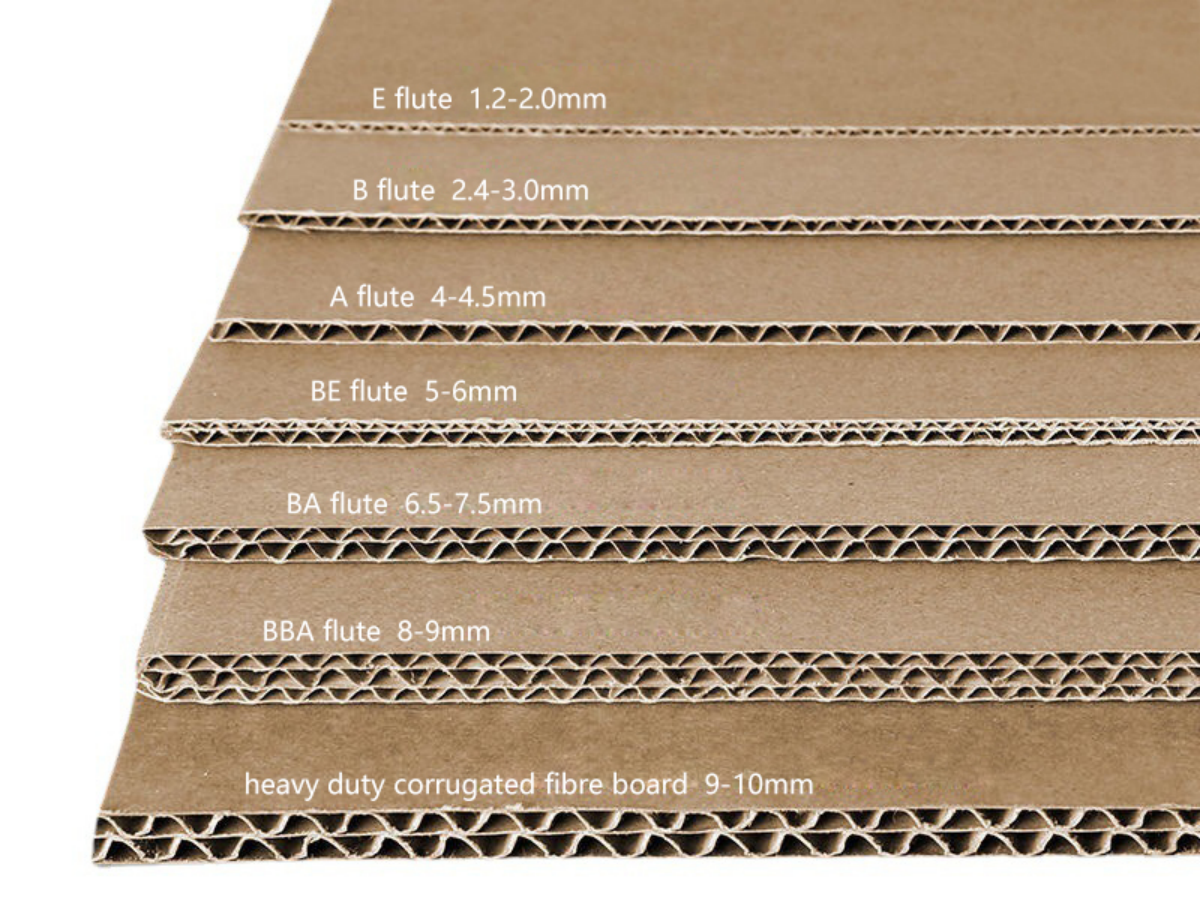

Material Structure and Application

Also known as corrugated cardboard. It is made of at least one layer of corrugated paper and one layer of box board paper (also called box board), which has good elasticity and extensibility. It is mainly used in the manufacture of carton, carton sandwich and other packaging materials for fragile goods. The main use of soil grass pulp and waste paper by pulping, made similar to the original cardboard, and then after mechanical processing rolled into corrugated, and then on its surface with sodium silicate and other adhesive and box board paper bonding.

Corrugated Paperboard Structure Diagram

Corrugated Paperboard Structure Diagram

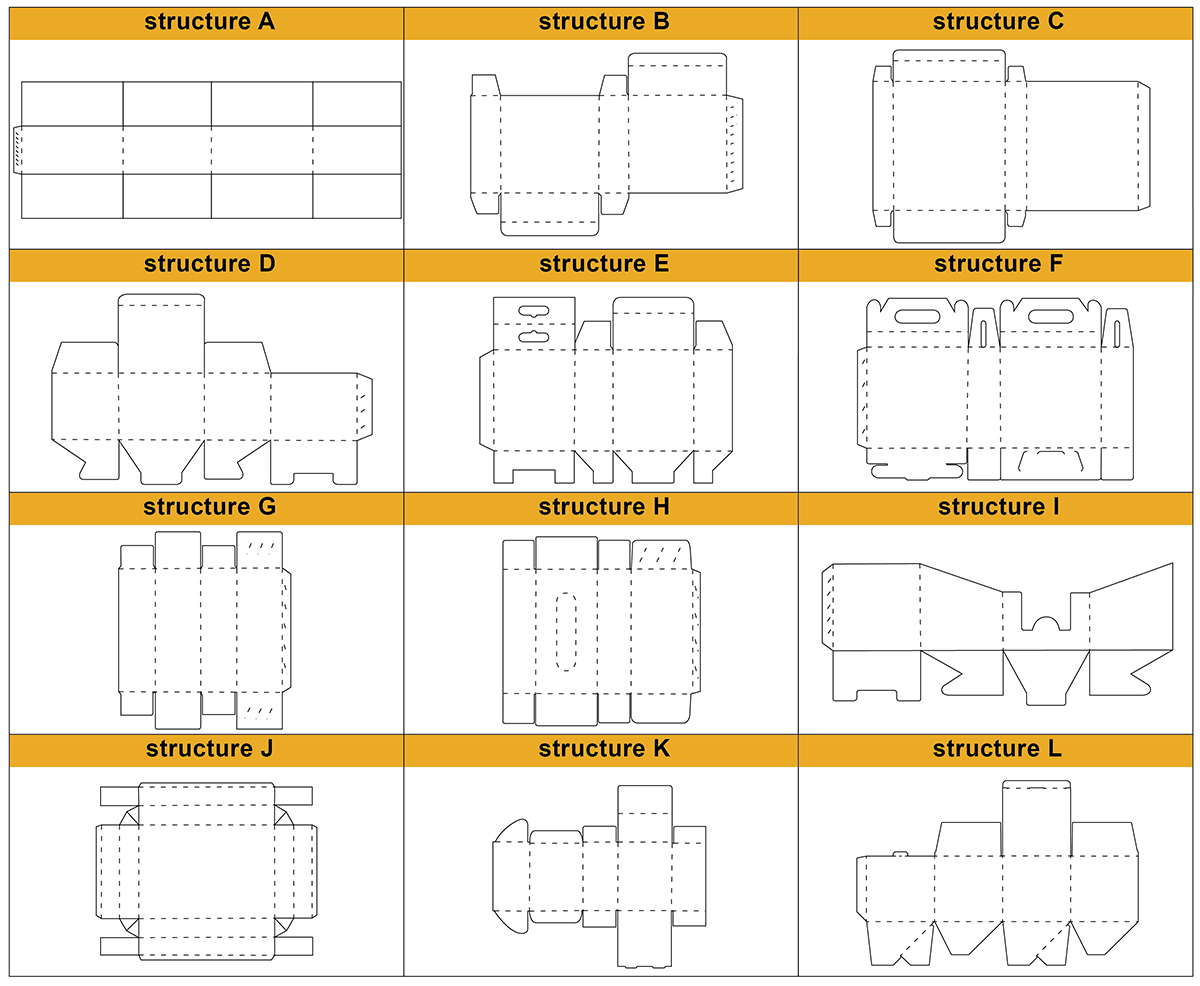

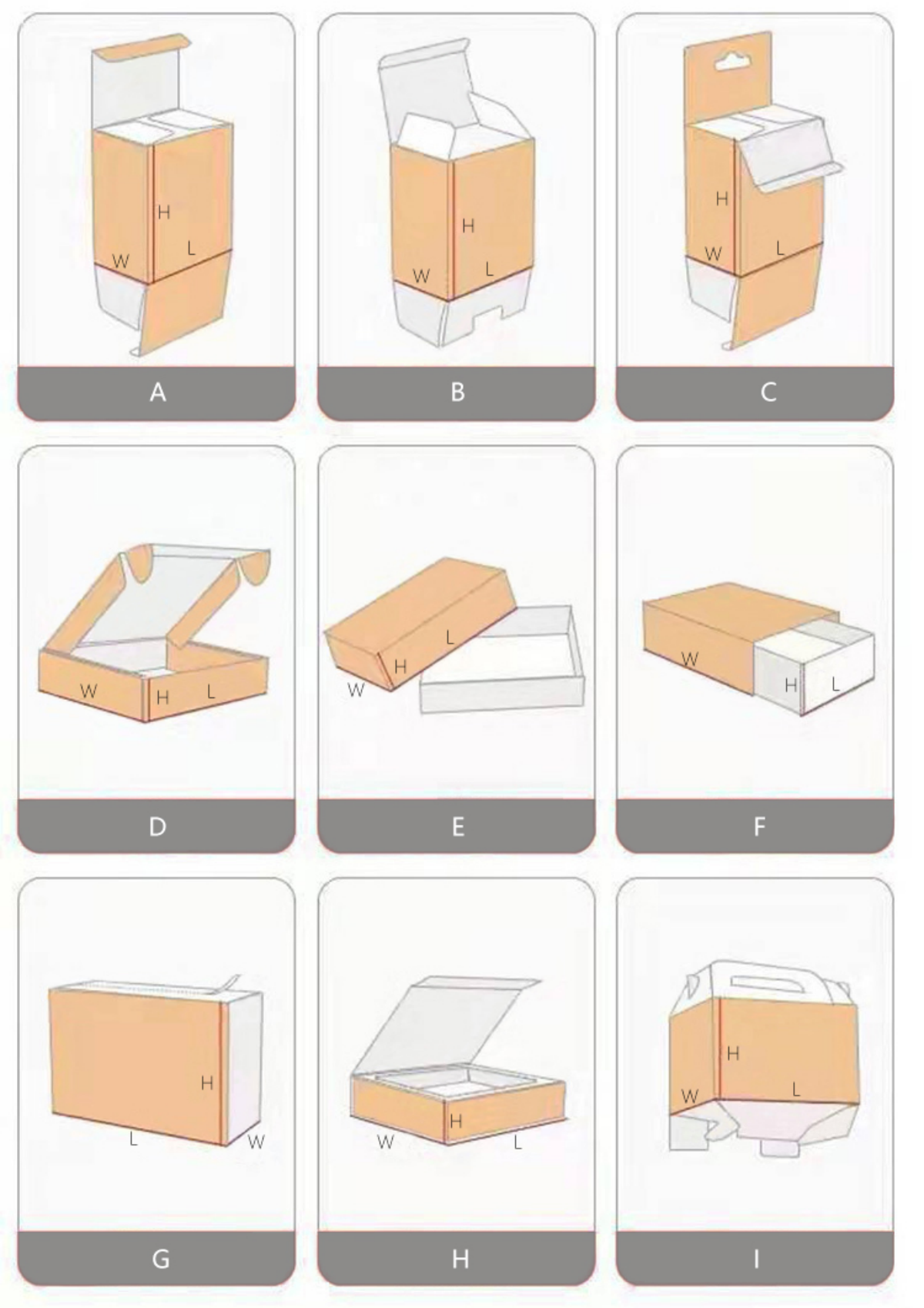

Box Type and Surface Treatment

These box type are used for reference, it can be customized as well.

Common Surface Treatment As Follows

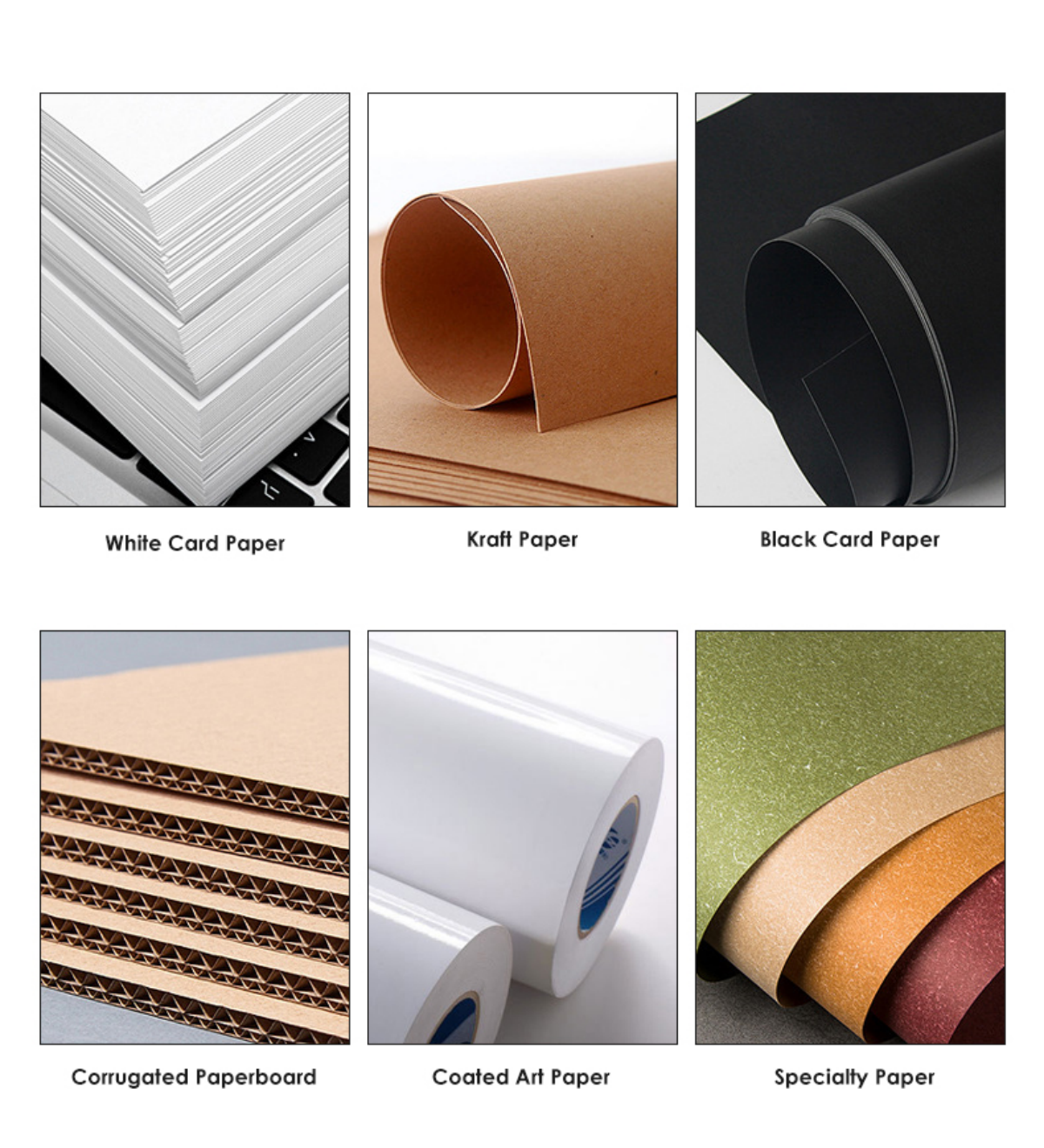

Paper Type

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Material Structure and Application

Paper cartons have become a popular choice for shipping products in major mailer malls. These eco-friendly and versatile displays offer a range of benefits, making them an attractive option for businesses looking to increase awareness of their products. Paper mailer boxes are easy to disassemble and install, and have low transportation costs. They are not only practical, but also in line with the retail industry’s growing emphasis on sustainability.

Flute based on the size of box , product weight and structure. The same flute can be select different gram for each layers.

Box Type and Finish Surface

Main structure for cartons as follow.

Surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment As Follows