Color printing Recycled Kraft Paper Box Corrugated Cardboard Packaging Box

Description

The brown color of kraft paper itself can make people feel a warm nostalgia.

Compared with plastic, glass and other packaging materials, the cost of kraft paper is 10 to 20 percent lower under the same barrier effect.

Basic Info

|

Product Name |

Recyclable Kraft Corrugated Box |

Surface Handling |

No Lamination |

|

Box Style |

OEM design |

Logo Printing |

Customized Logo |

|

Material Structure |

Kraft paper + Corrugated Paper + Kraft Paper |

Origin |

Ningbo |

|

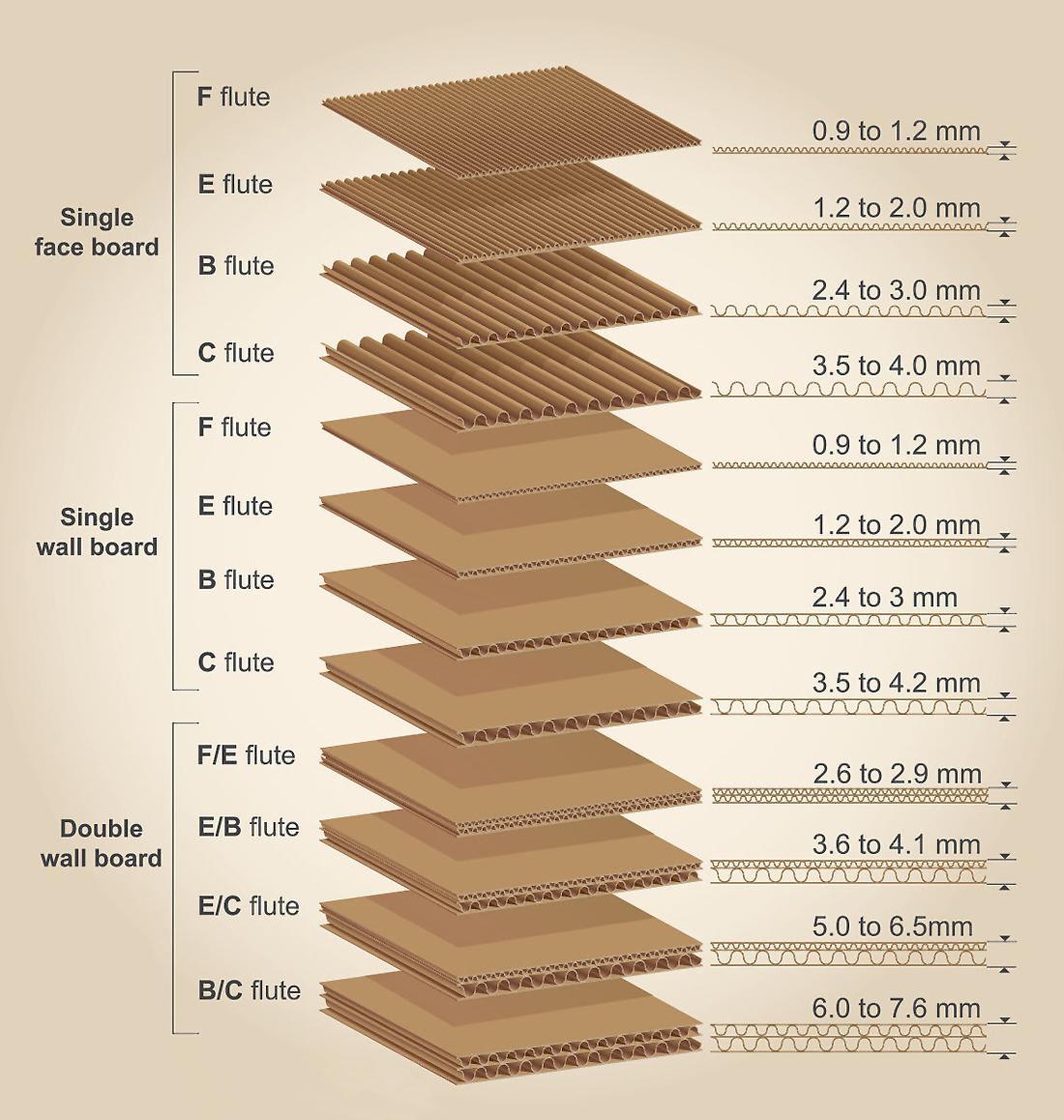

Flute Type |

E Flute, B Flute, C Flute, BE Flute |

Sample |

Accept custom samples |

|

Shape |

Rectangle |

Sample Time |

5-7 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

10-15 days based on quantity |

|

Printing |

Offset Printing, UV printing |

Transport Package |

Strong 5 ply Corrugated Carton |

|

Type |

Single Printing Box |

MOQ |

2000PCS |

Detailed Images

Kraft paper with a thickness of more than 150g is called kraft cardboard. Because of its thicker thickness, higher hardness and stiffness, it is mainly used to make cardboard boxes, which can effectively protect products.

Offset Printing Kraft Paper Box & Flexographic Printing Kraft Paper Box

Material Structure and Application

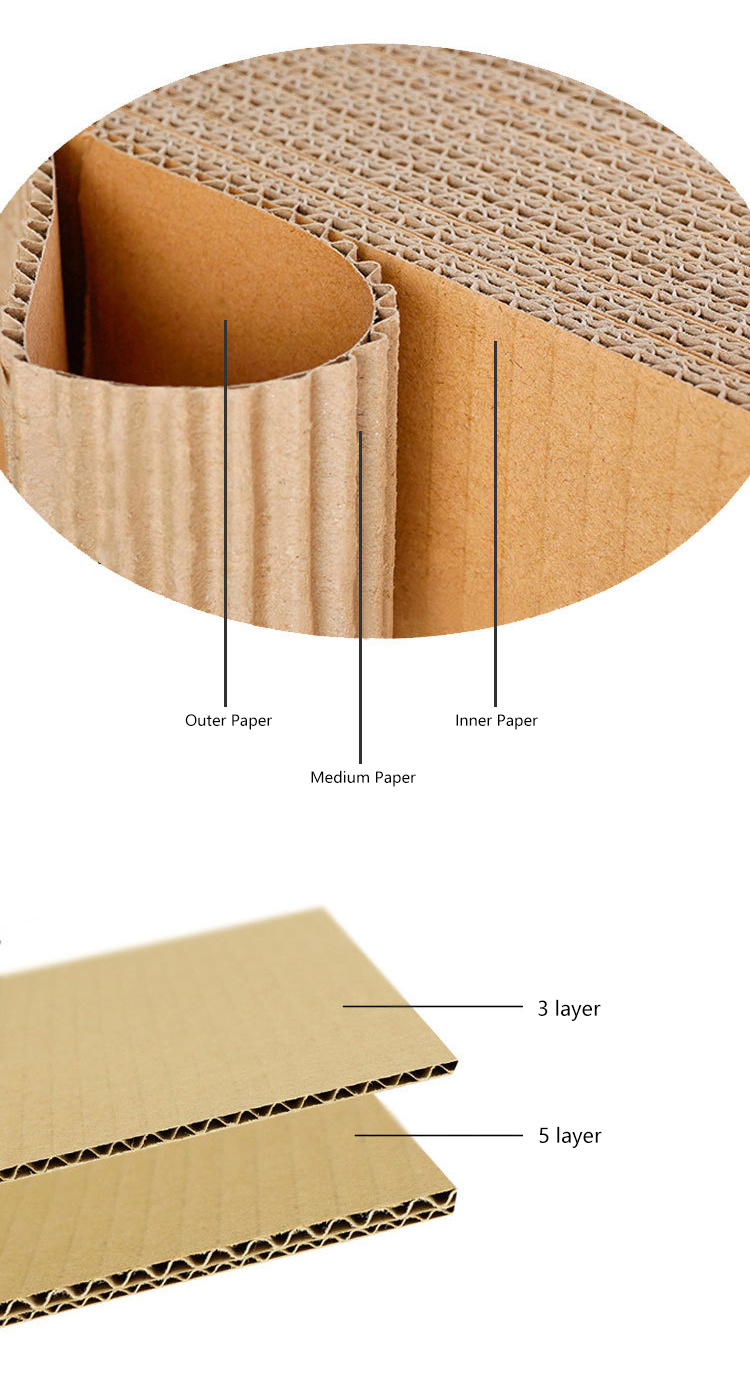

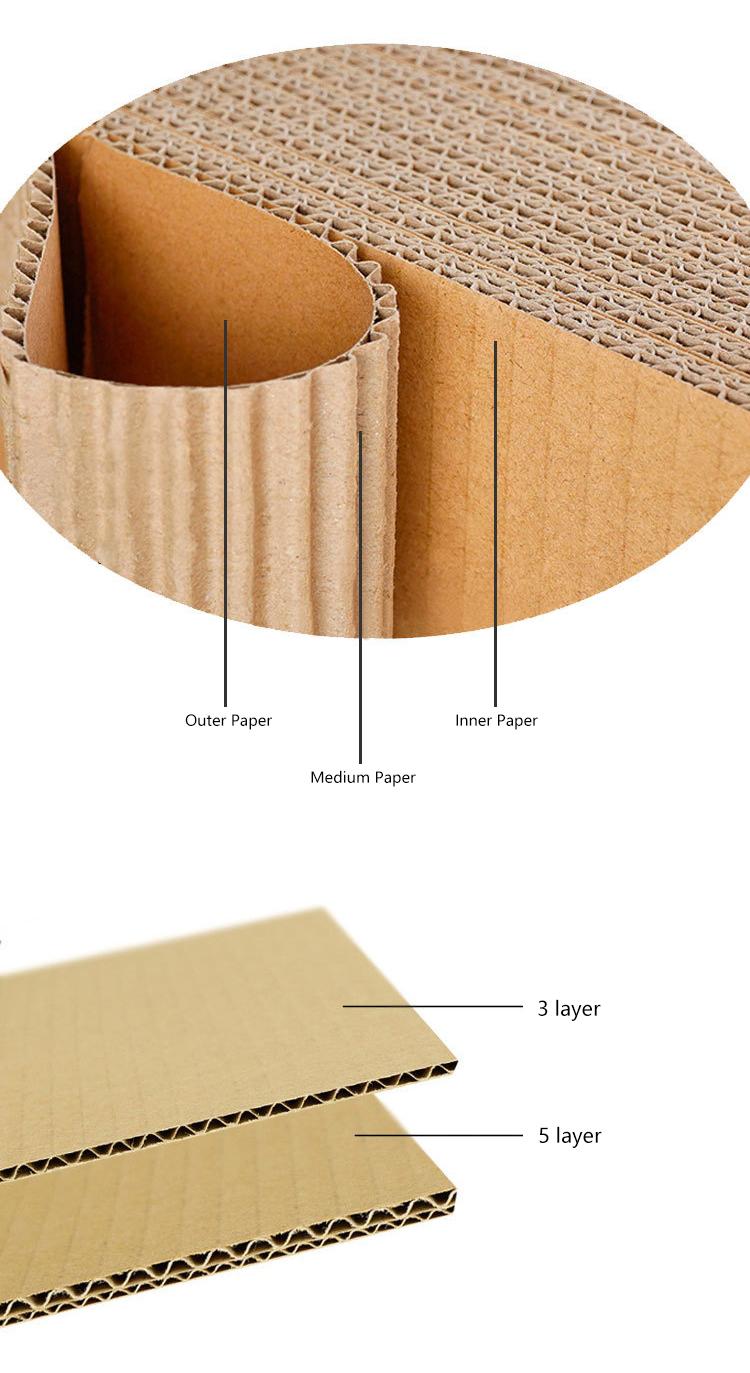

Corrugated cardboard is composed of at least one layer of corrugated paper and one layer of cardboard. It has high mechanical strength and can withstand collision and fall during handling. The actual performance of corrugated cardboard depends on three factors: the characteristics of core paper and cardboard and the structure of cardboard itself.

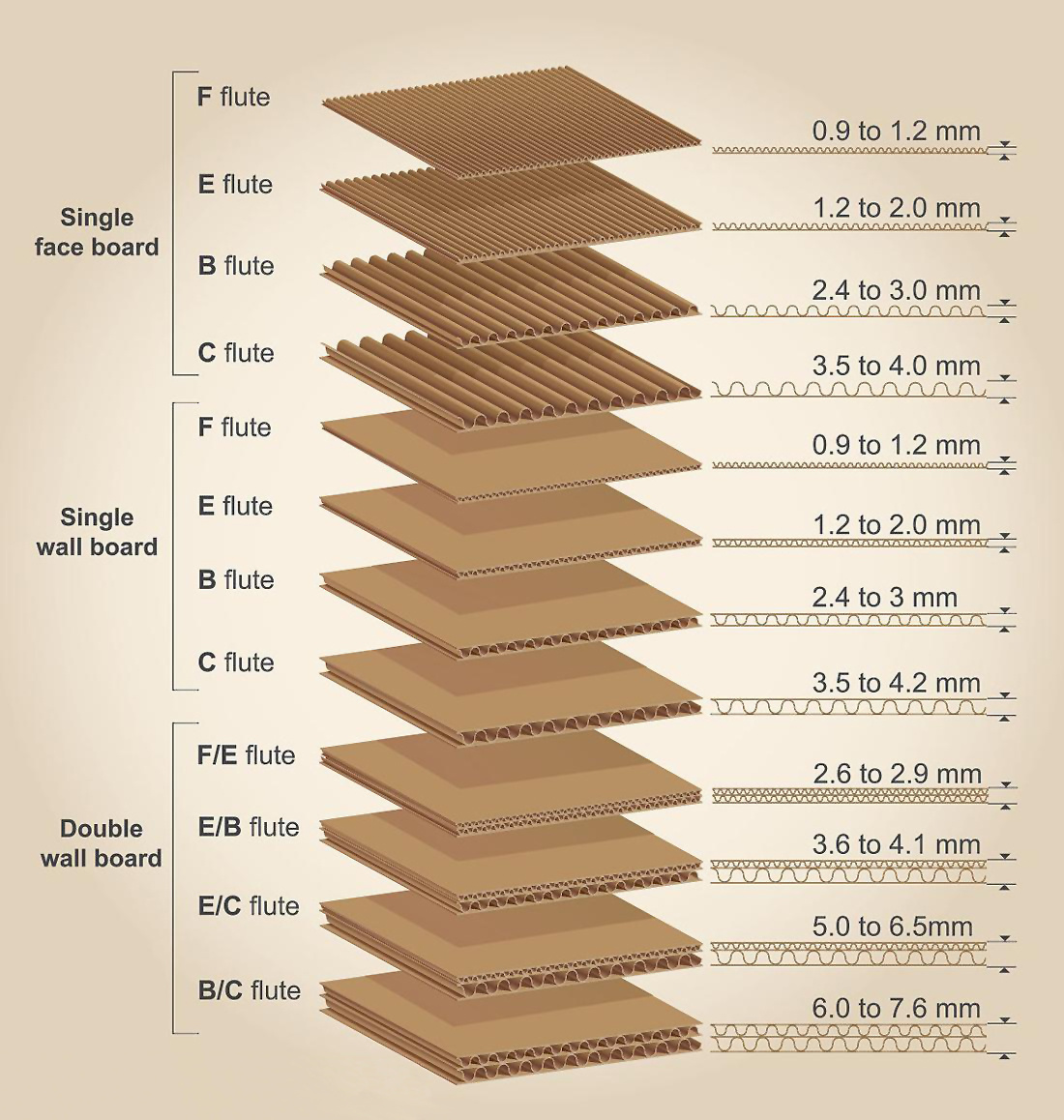

The larger the pit diameter of corrugated board the stronger

Corrugated Paperboard Structure Diagram

Application

Kraft paper is a tough and water-resistant packaging paper, which is widely used in carton, carton, handbag, color box, gift box, wine box, document bag, clothing tag and other fields.

Box Type and Finish Surface

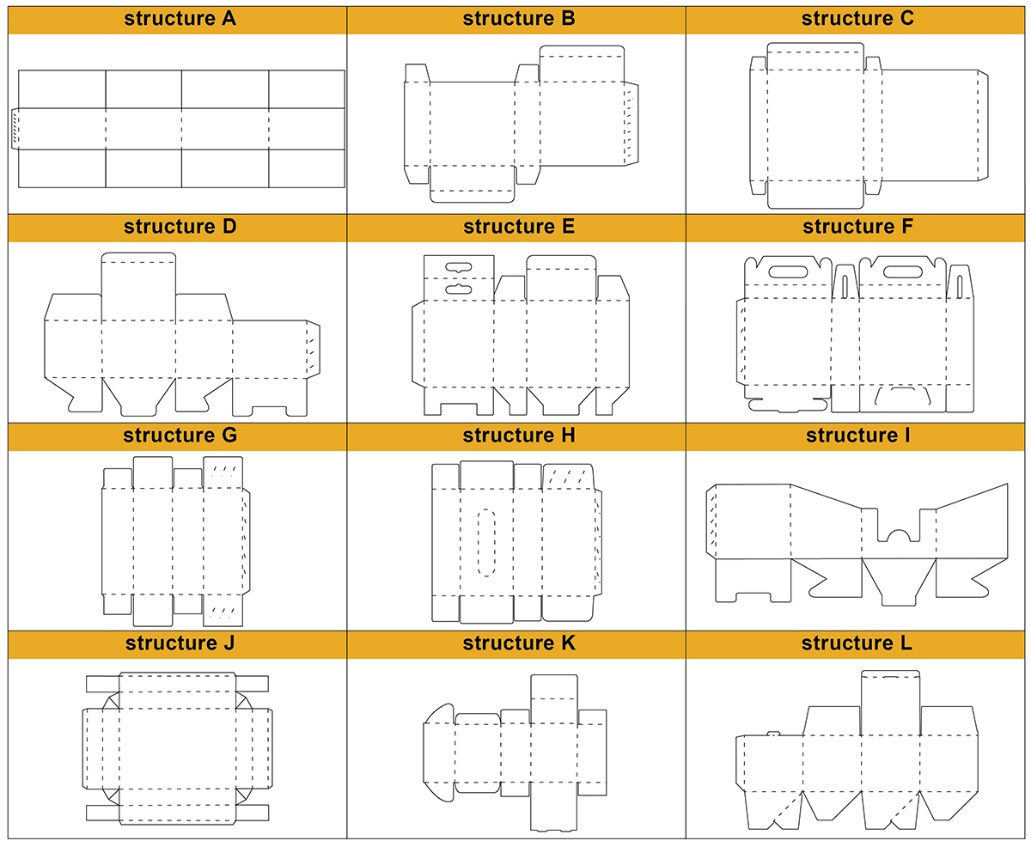

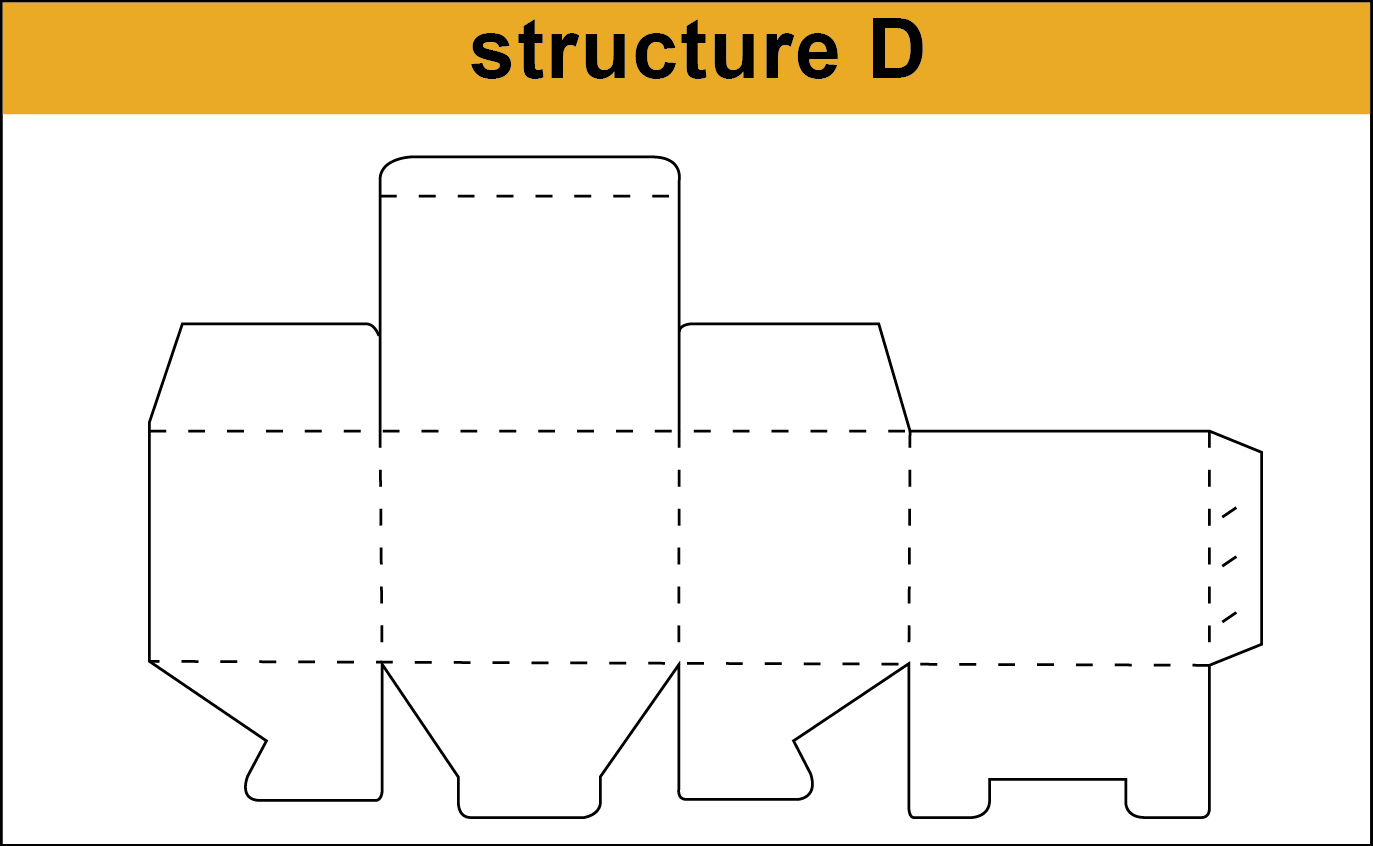

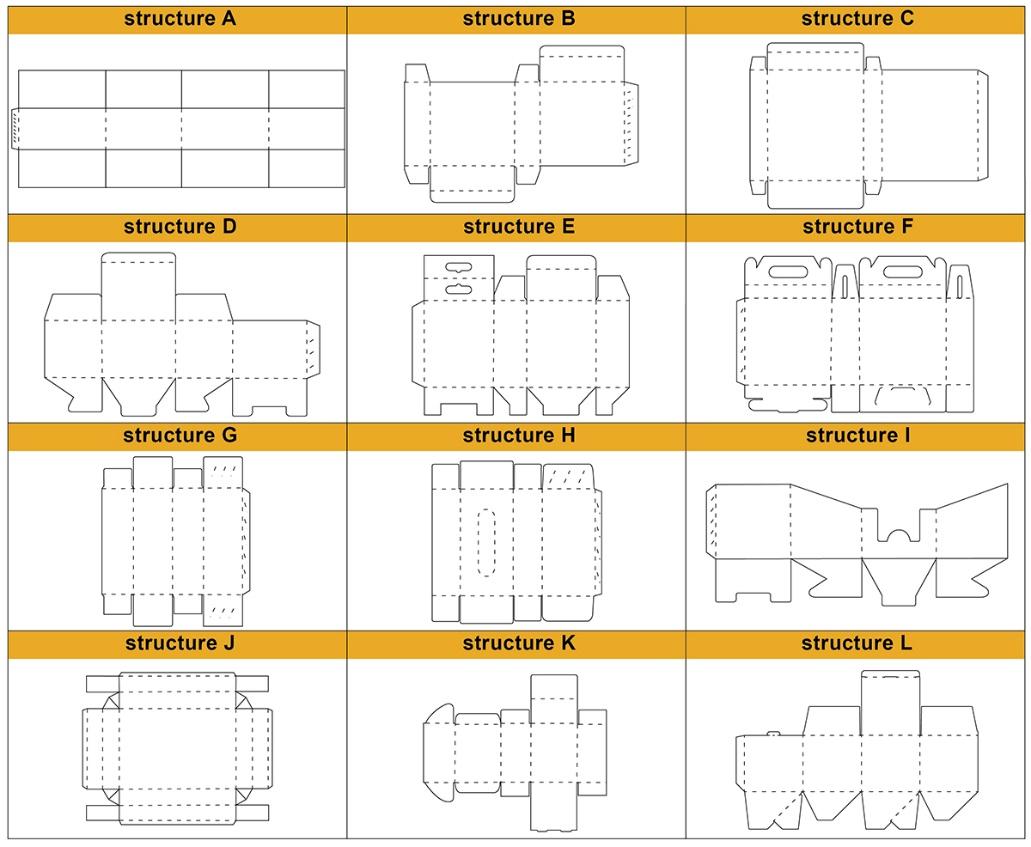

The box type as followa

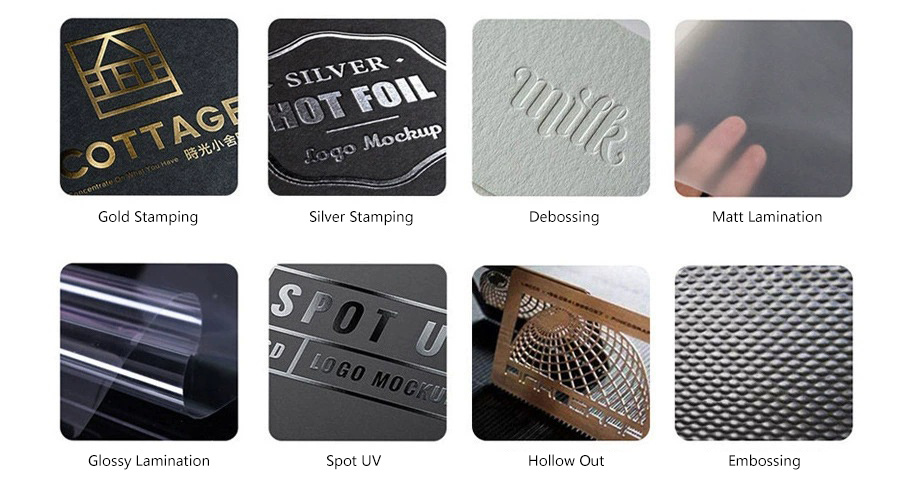

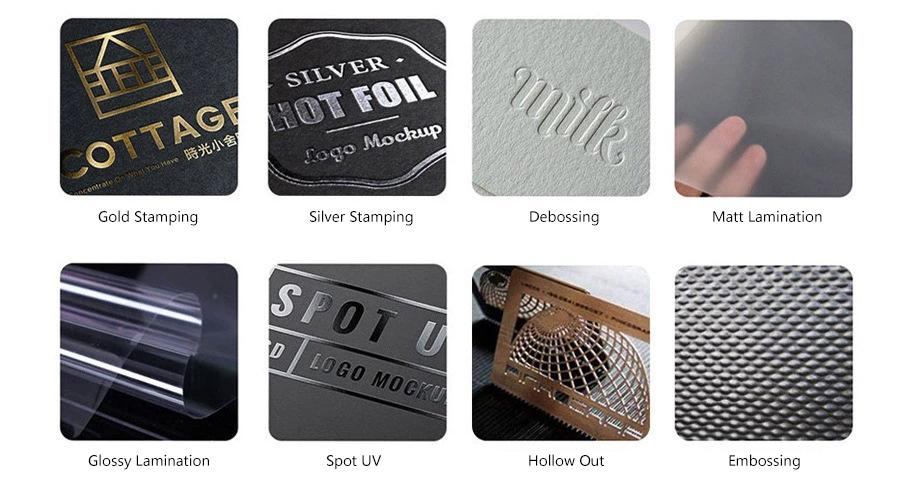

The surface treatment process of printed items mainly refers to the post-processing procedure of printed products in order to increase their durability, make them easier to transport and store, and improve their appearance by giving them a more upscale, ethereal, and high-grade feel. Lamination, spot UV, gold stamping, silver stamping, concave-convex, embossing, hollow-carved, laser technology, etc. are all surface treatments for printing.

Common Surface Treatment as Follows

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Corrugated cardboard is composed of at least one layer of corrugated paper and one layer of cardboard. It has high mechanical strength and can withstand collision and fall during handling. The actual performance of corrugated cardboard depends on three factors: the characteristics of core paper and cardboard and the structure of cardboard itself.

The larger the pit diameter of corrugated board the stronger

Corrugated Paperboard Structure Diagram

Application

Kraft paper is a tough and water-resistant packaging paper, which is widely used in carton, carton, handbag, color box, gift box, wine box, document bag, clothing tag and other fields.

The box type as followa

The surface treatment process of printed items mainly refers to the post-processing procedure of printed products in order to increase their durability, make them easier to transport and store, and improve their appearance by giving them a more upscale, ethereal, and high-grade feel. Lamination, spot UV, gold stamping, silver stamping, concave-convex, embossing, hollow-carved, laser technology, etc. are all surface treatments for printing.

Common Surface Treatment as Follows