Creative Design White Card Paper Coffee Tea Bag Packaging Box with Window

Description

This box consists of an inner box and an outer box. The outer box is envelope with window.

In order to facilitate your design of printed content, we will provide you with structural drawings for free.

Depending on the size, weight, and intended usage of the product, we will select the right materials for you.

Basic Info.

| Product Name | Envelope Packaging Box | Surface Handling | Matt Lamination, Glossy lamination, spot UV. |

| Box Style | Nested Paper Box | Logo Printing | Customized Logo |

| Material Structure | High Grade White Card Paper | Origin | Ningbo |

| Material Weight | 400gram | Sample | Accept custom samples |

| Shape | Rectangle | Sample Time | 5-8 Working Days |

| Color | CMYK Color, Pantone Color | Production Lead Time | 8-12 Working Days Based on Quantity |

| Printing | Offset Printing | Transport Package | Strong 5 ply Corrugated Carton |

| Type | Single Printing Box | MOQ | 2000PCS |

Detailed Images

A beautiful box is based on the success of every detail.

We have a professional team to check the structure and printing quality of the box. The cutter mould master will adjust the design and cutter mould according to the different materials.

Please communicate with the salesperson carefully for specific requirements.

Material Structure and Application

The commonly used materials of paper cards are: white cardboard, black cardboard, kraft paper, coated paper and special paper.

Advantages of white card paper: solid, relatively durable, good smoothness, and rich and full colors printed.

The material characteristics of coated paper: both whiteness and glossiness are very good. When printing, pictures and pictures can show a three-dimensional sense, but its firmness is not as good as that of white cardboard.

Advantages of kraft paper: It has a high toughness and firmness, and is not easy to tear. Kraft paper is generally suitable for printing some monochrome or not rich in color.

Advantages of black card paper: It is solid and durable, and its color is black. Because the black card paper itself is black, its disadvantage is that it cannot print color, but it can be used for gilding, silver stamping and other processes.

Appliance

Box Type and Finish Surface

Box structure can be customized according to your requirements.

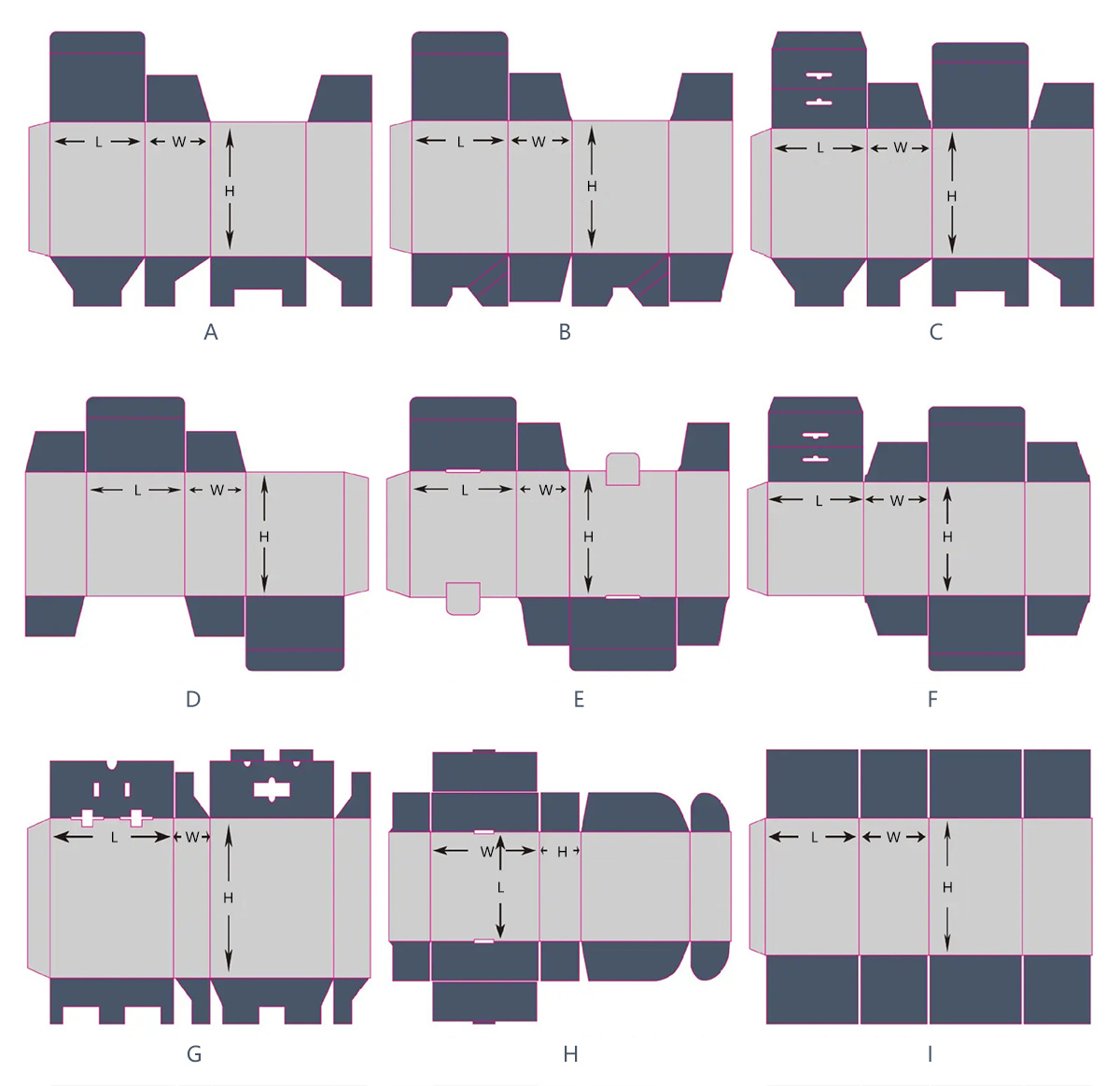

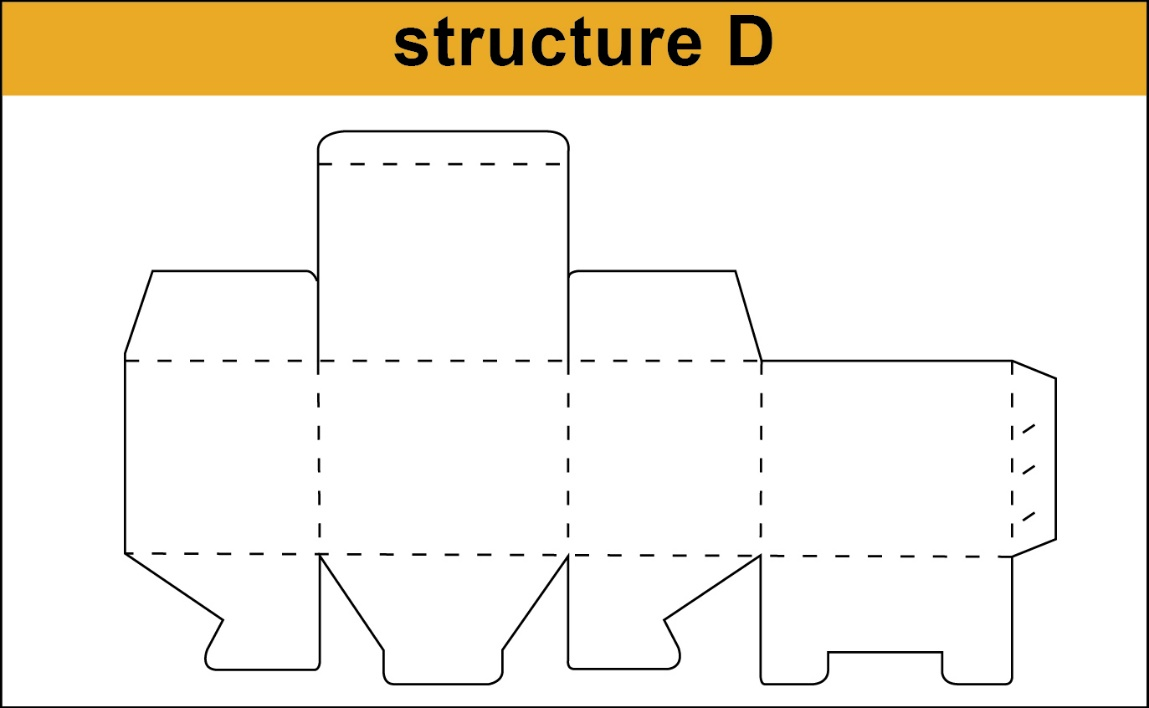

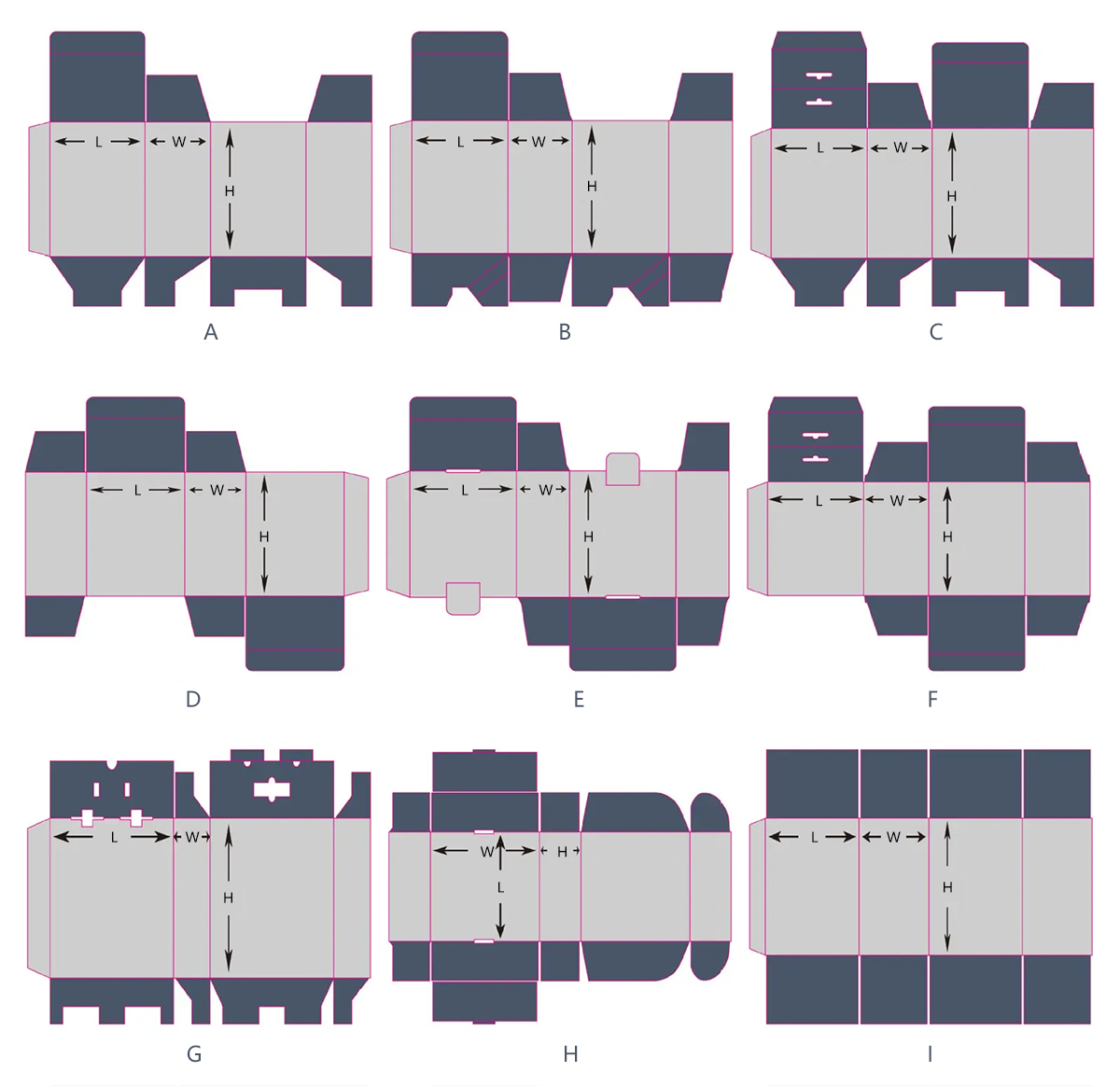

The box type as follow

Finish Surface

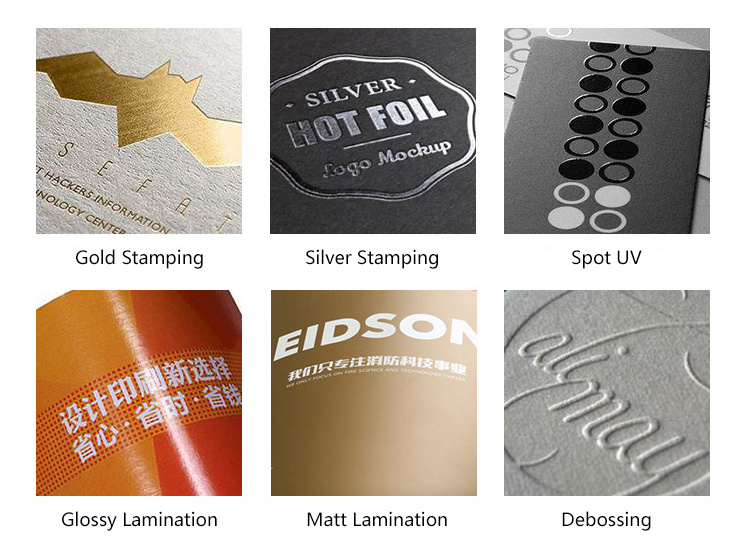

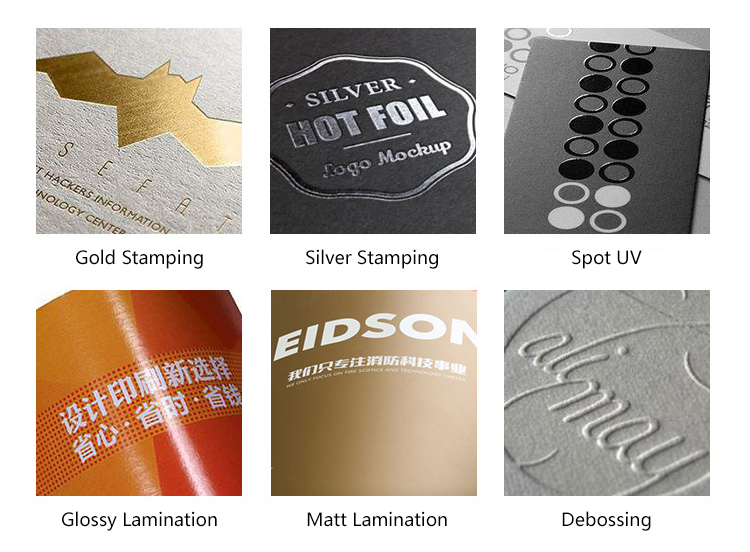

Lamination is the most commonly used surface treatment method. The price is cheap and the effect is good. Lamination film refers to the use of transparent plastic film to protect and increase the gloss of printed materials by hot pressing. The types of laminated films are glossy films, matt films, tactile films, laser films, removable films, etc.

In addition to lamination treatment, the surface of printed matter can also be treated with "varnishing", which can also prevent scratches, fading, dirt, and prolong the service life of tag printed matter.

Common Surface Treatment As Follows

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

The commonly used materials of paper cards are: white cardboard, black cardboard, kraft paper, coated paper and special paper.

Advantages of white card paper: solid, relatively durable, good smoothness, and rich and full colors printed.

The material characteristics of coated paper: both whiteness and glossiness are very good. When printing, pictures and pictures can show a three-dimensional sense, but its firmness is not as good as that of white cardboard.

Advantages of kraft paper: It has a high toughness and firmness, and is not easy to tear. Kraft paper is generally suitable for printing some monochrome or not rich in color.

Advantages of black card paper: It is solid and durable, and its color is black. Because the black card paper itself is black, its disadvantage is that it cannot print color, but it can be used for gilding, silver stamping and other processes.

Appliance

Box structure can be customized according to your requirements.

The box type as follow

Finish Surface

Lamination is the most commonly used surface treatment method. The price is cheap and the effect is good. Lamination film refers to the use of transparent plastic film to protect and increase the gloss of printed materials by hot pressing. The types of laminated films are glossy films, matt films, tactile films, laser films, removable films, etc.

In addition to lamination treatment, the surface of printed matter can also be treated with “varnishing”, which can also prevent scratches, fading, dirt, and prolong the service life of tag printed matter.

Common Surface Treatment As Follows