Custom Small Luxury Rigid Cardboard Earrings Pendant Packaging Gift Box

Description

The drawer type box is light and flexible, beautiful in shape, and can be designed in parallel multi-layer or single-layer. It can be opened or closed by pulling, and has great storage capacity.

This type of box is produced by semi-automatic machine and handmade.

The box is non collapsible.

Basic Info

|

Product Name |

Luxury Drawer Packaging Box |

Surface Handling |

Glossy lamination, matte lamination, Embossed, Spot UV |

|

Box Style |

Drawer Type Box |

Logo Printing |

Customized Logo |

|

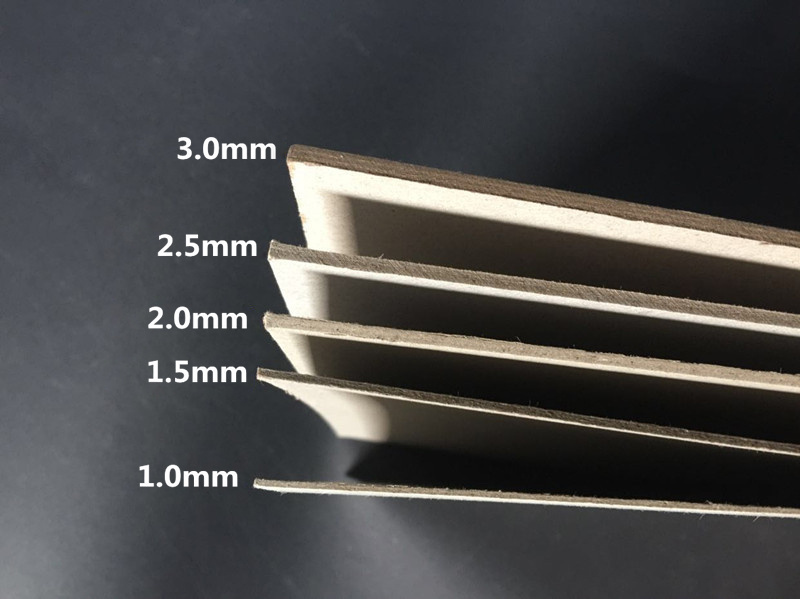

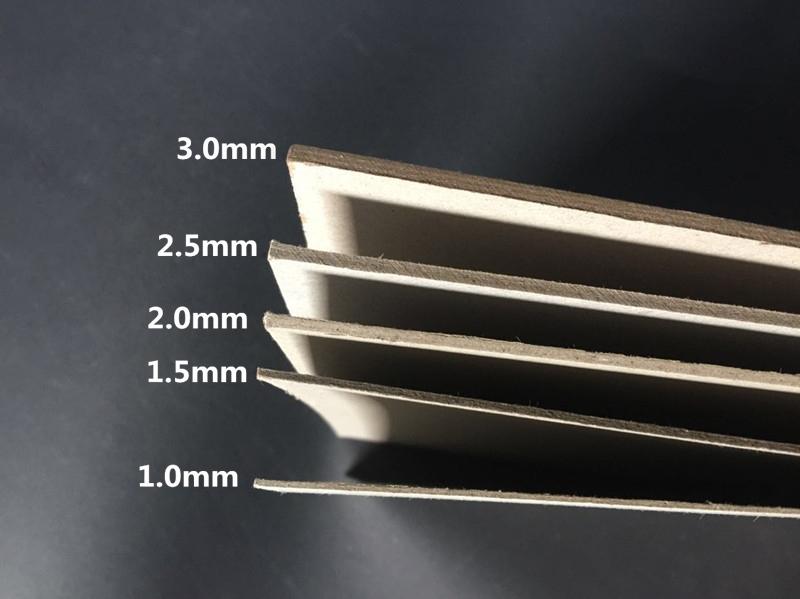

Material thickness |

1 mm, 1.5mm, 2 mm, 2.5 gray board |

Origin |

Ningbo |

|

Materials type |

Single gray board, double gray board, single white board, single black board... |

Sample |

Accept custom samples |

|

Shape |

Square and Rectangle |

Sample Time |

7-10 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

10-15 working days based on quantity |

|

Printing |

Offset Printing, UV Printing |

Transport Package |

Strong 5 ply Corrugated Carton |

|

Type |

Single Printing Box |

MOQ |

2000PCS |

Detailed Images

We have full automatic mechanical equipment for classic gray board gift box.

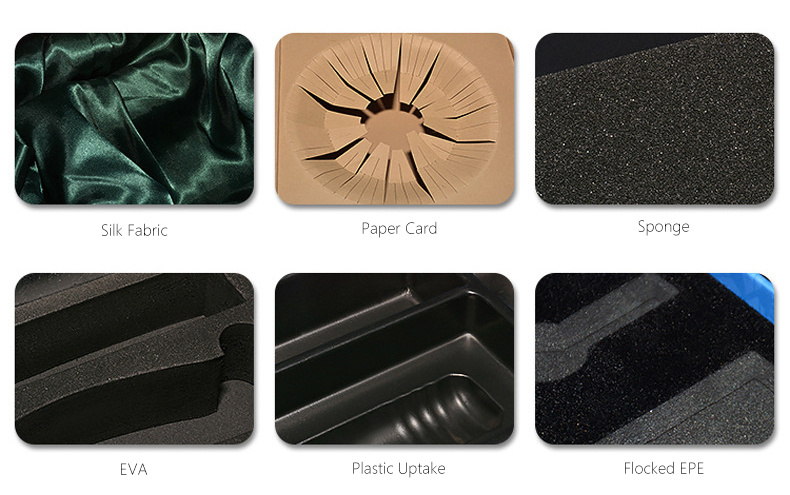

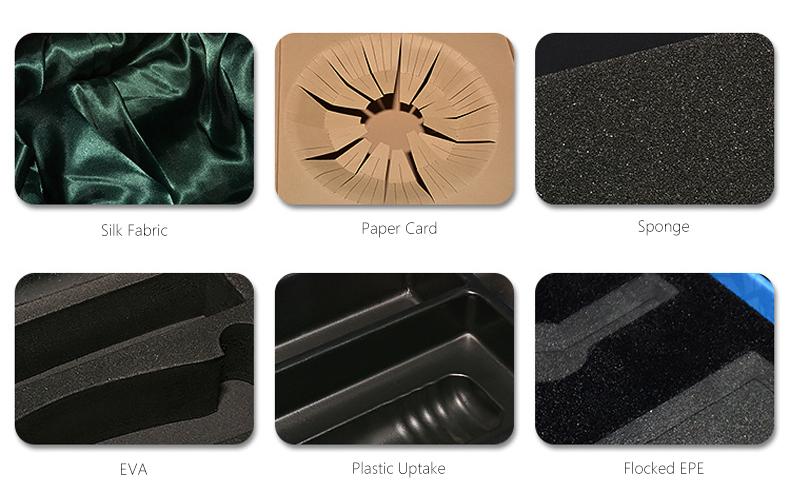

The material and size of the insert can be customized according to the product.

Box size will be adjusted by the die-cut designer for various materials. Please attach more details below.

Material Structure and Application

The drawer box is divided into an inner box and an envelope, which are opened and closed by pulling.

It and up bottom cover box are both better packaging methods with a sense of texture, and have a sense of opening ceremony. They are suitable for most kinds of products.

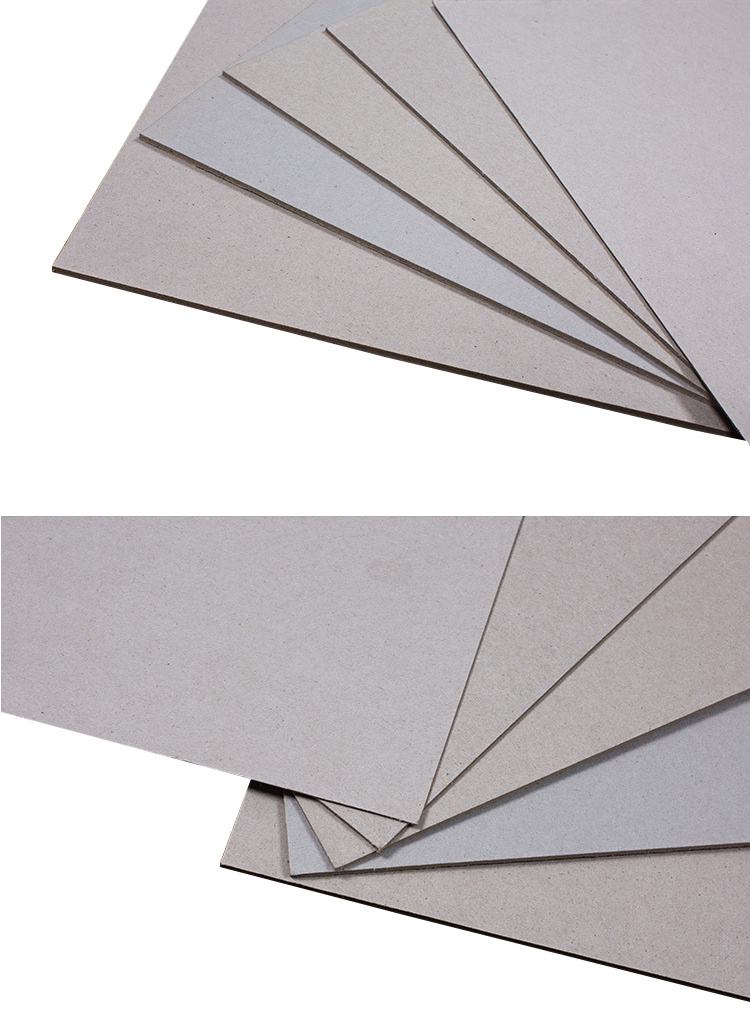

Gray board Structure Diagram

The commonly used thickness of gray cardboard paper is 1mm, 1.5mm, 2mm, 2.5mm and 3mm.

Surface Paper Type

Coated Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for

printing advanced picture books, calendars and books, etc.

Specialty paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

Insert Material

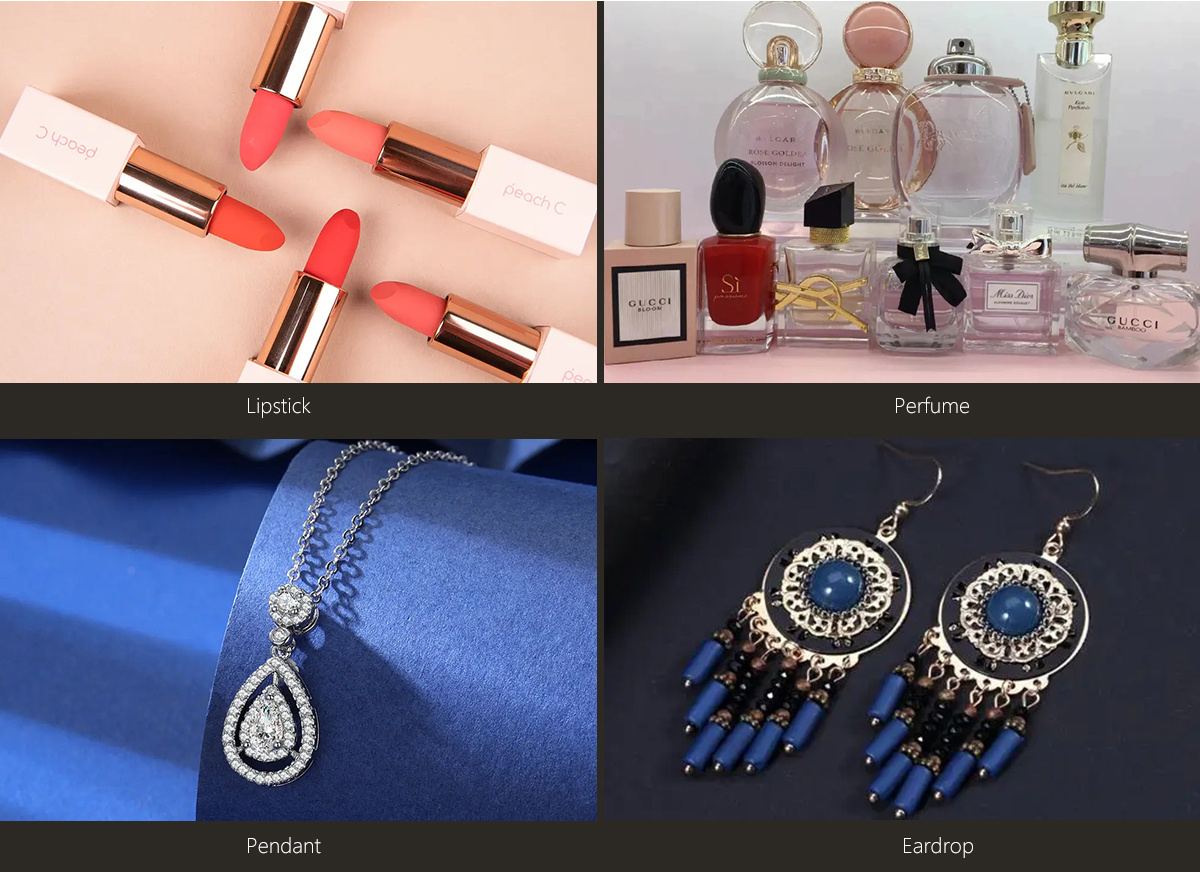

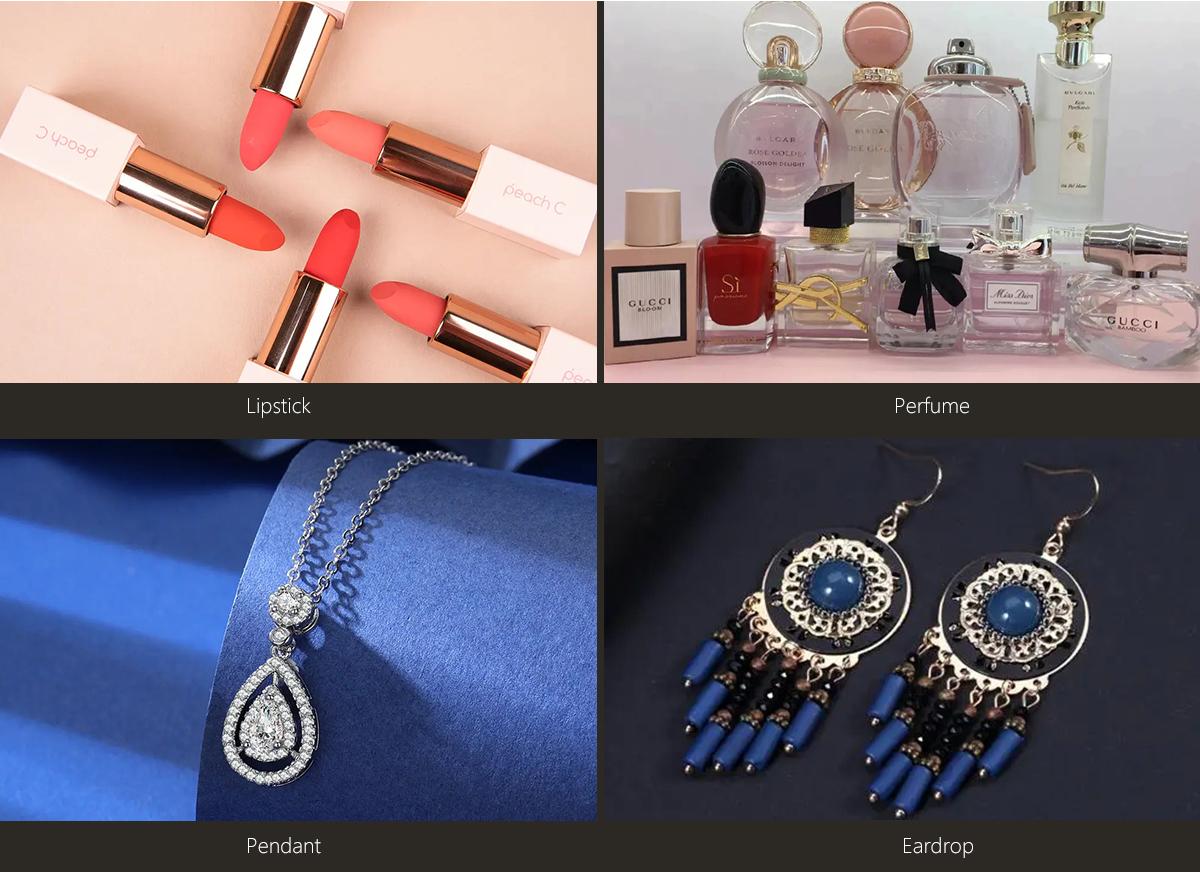

Application

Earrings, pendants, perfume, lipstick, and other feminine goods are frequently packaged in drawer gift boxes.

Box Type and Finish Surface

The box type as follow

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment as Follows

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

The drawer box is divided into an inner box and an envelope, which are opened and closed by pulling.

It and up bottom cover box are both better packaging methods with a sense of texture, and have a sense of opening ceremony. They are suitable for most kinds of products.

Gray board Structure Diagram

The commonly used thickness of gray cardboard paper is 1mm, 1.5mm, 2mm, 2.5mm and 3mm.

Surface Paper Type

Coated Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for

printing advanced picture books, calendars and books, etc.

Specialty paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

Insert Material

Application

Earrings, pendants, perfume, lipstick, and other feminine goods are frequently packaged in drawer gift boxes.

The box type as follow

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment as Follows