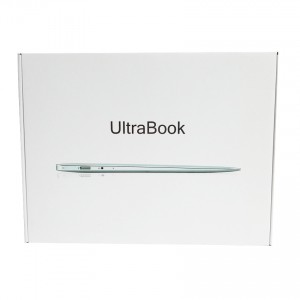

Customize Design Printed Firm Corrugated Package Paper Box with lock

Description

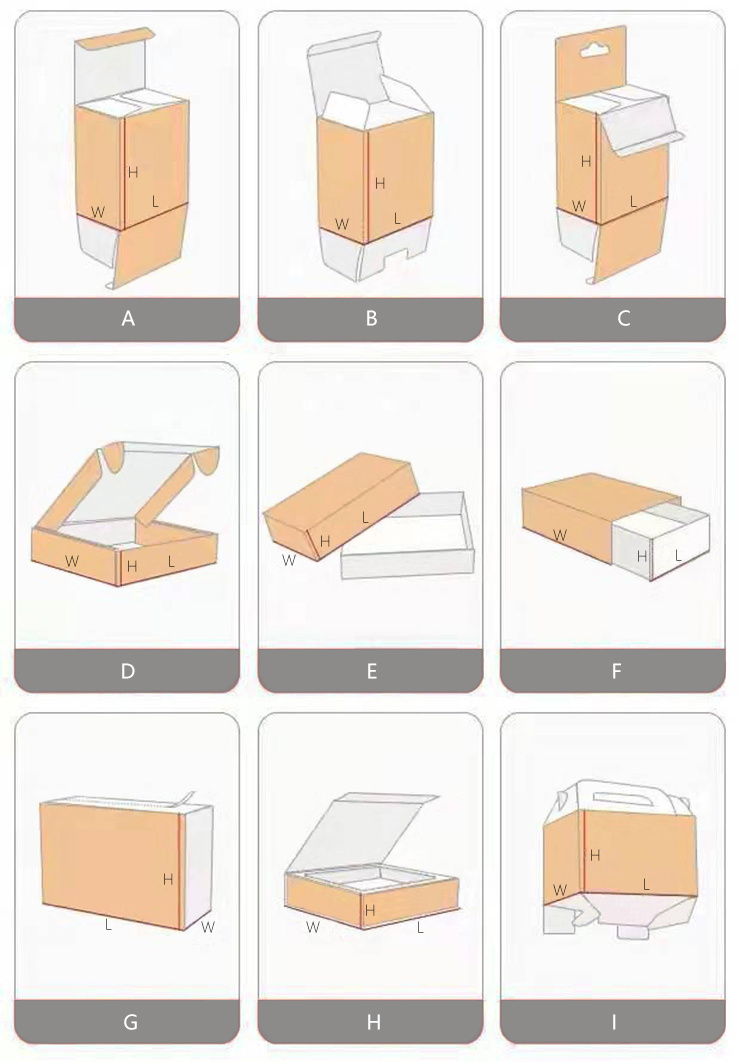

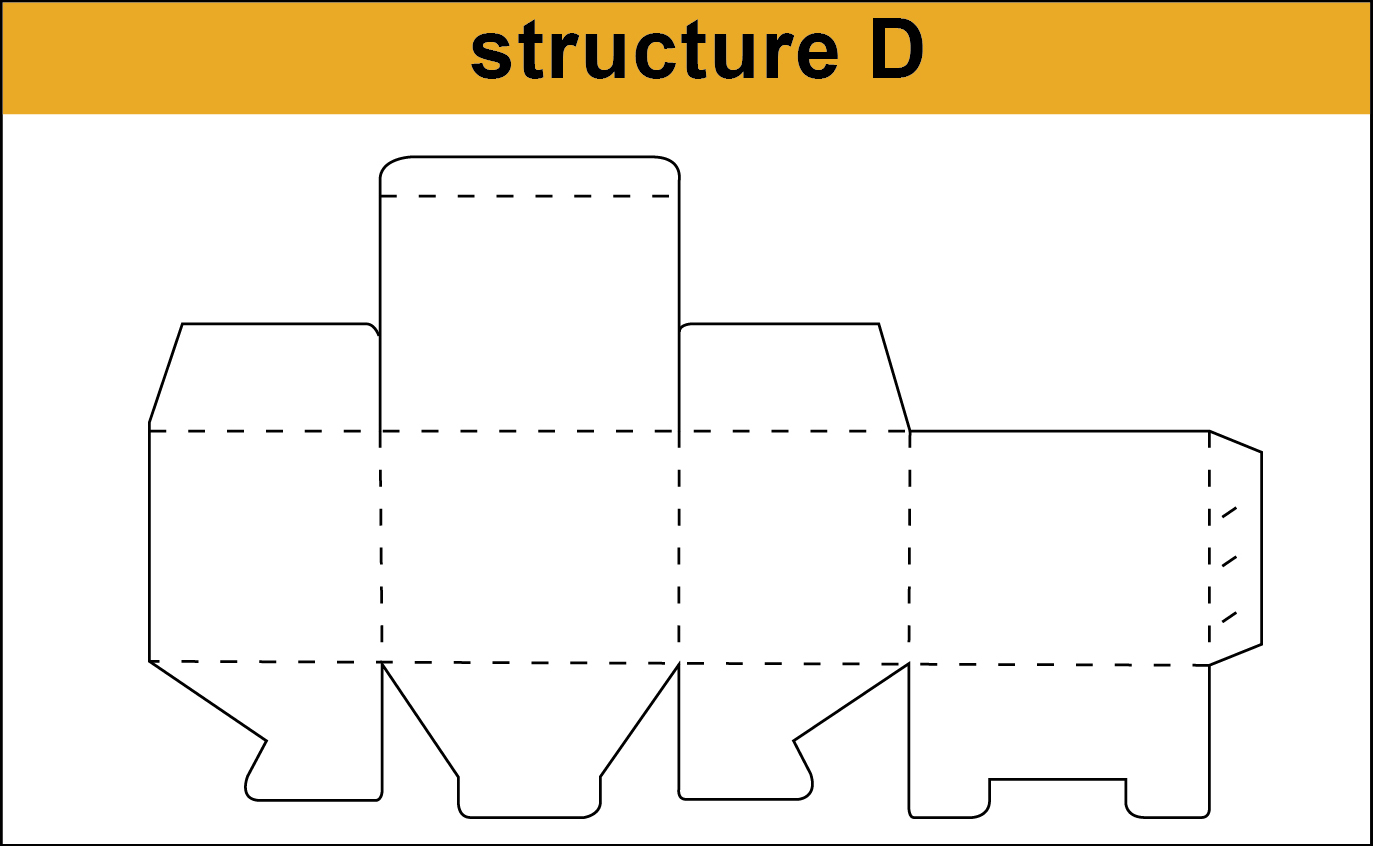

Structure: D structure with top lock

Feature: 1) Top open with lock;

2)Recyclable materials.

Samples: accept,

free for no printed sample;

Digital printing sample and bulk printing sample.

Lead time: 1-50000pcs, 7-14 working days after confirmed file.

≥50000pcs, to be negotiated

Basic Info.

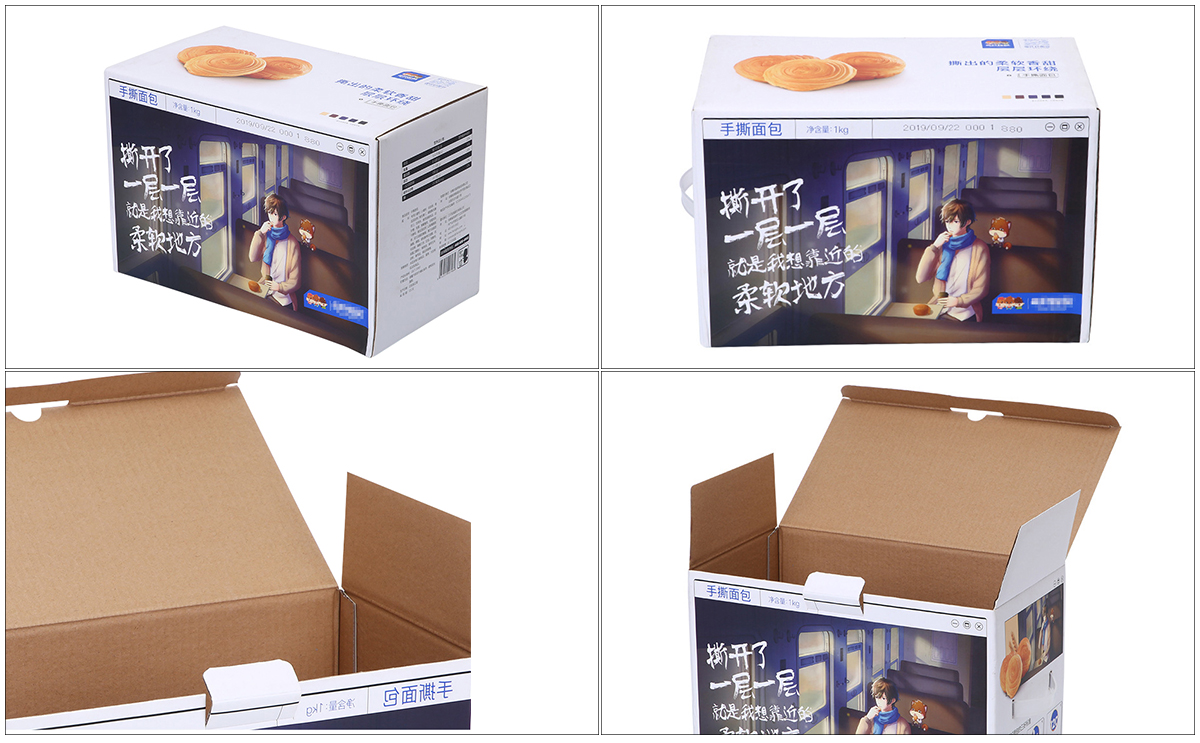

| Product Name | Printed Carton Box | Surface Handling | Glossy Lamination, Matte Lamination |

| Box Style | Cover with Lock Catch | Logo Printing | OEM |

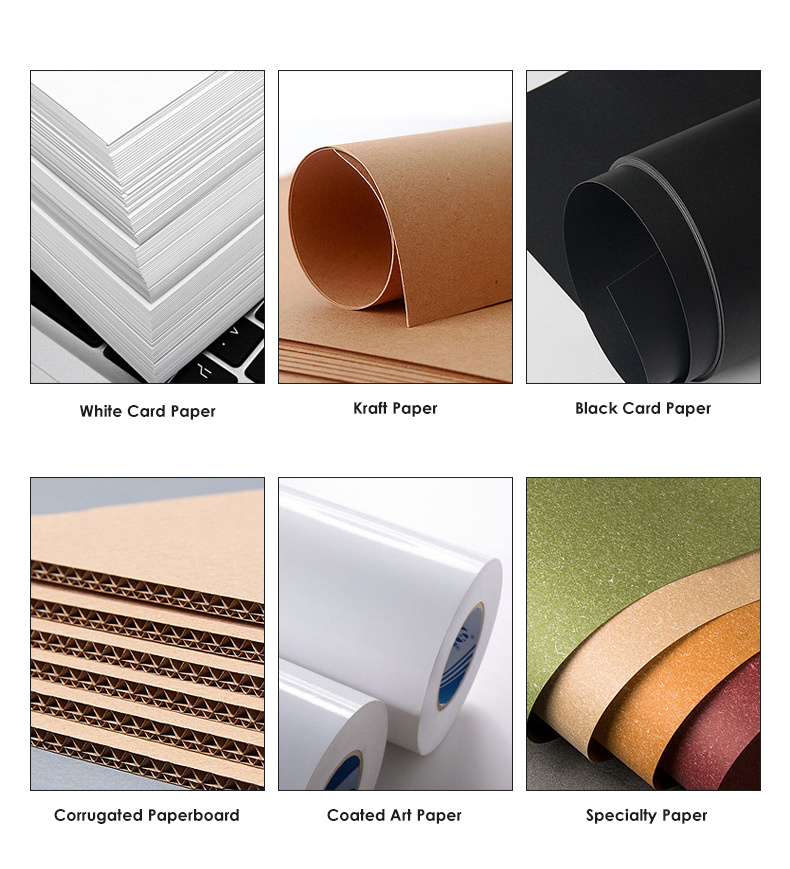

| Material Structure | White Board + Corrugated Paper + White Board/Kraft Paper | Origin | Ningbo,China. |

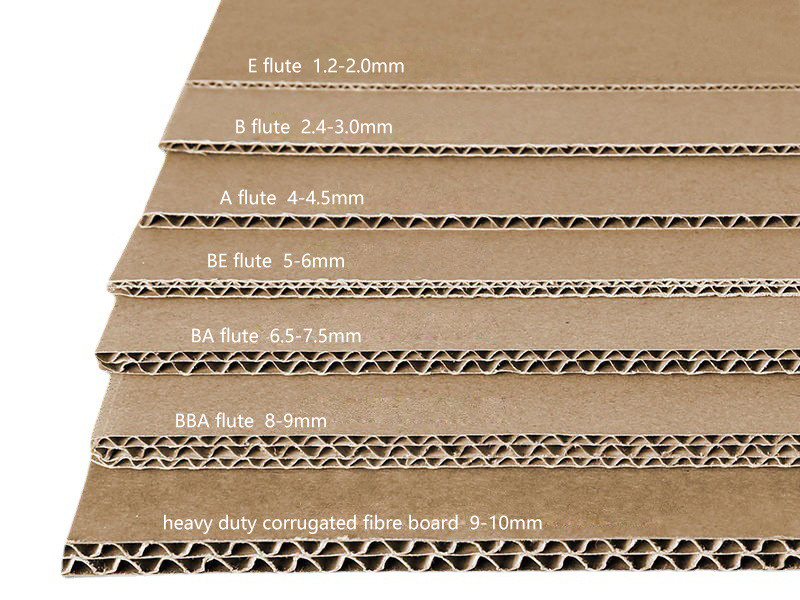

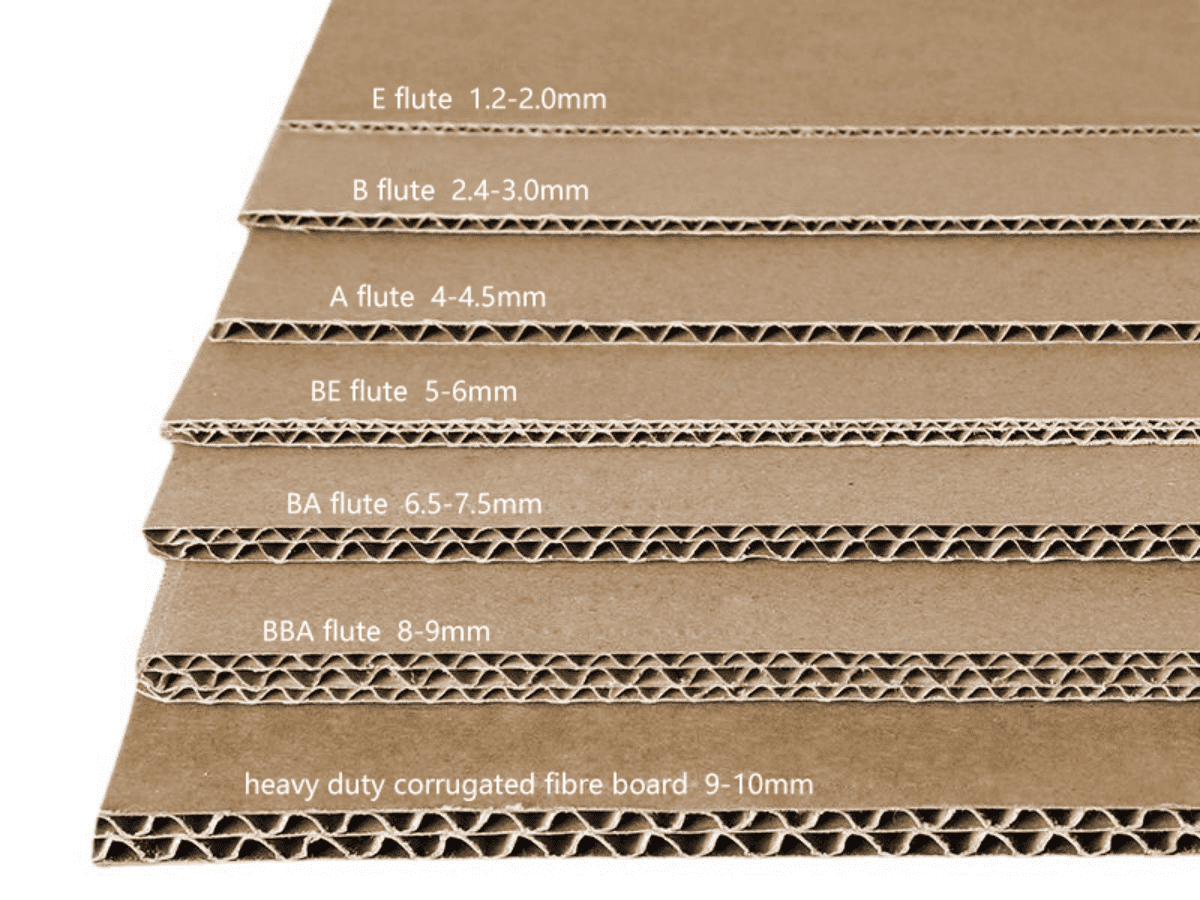

| Materials Weight | 250gsm White grayboard/120/150 White Kraft, E flute/B flute | Thickness | 2mm, 3mm, 4mm, 5mm |

| Shape | Rectangle | Sample Time | 5-7 Working Days |

| Color | CMYK Color, Pantone Color | MOQ | 2000PCS |

| Printing | Offset Printing,flexo printing | Transport Package | Strong 5 ply Corrugated Carton |

| Artwork | AI,CAD, PDF,etc. | Shipping | EXW,FOB,CIF, DDU ,etc. |

Detailed Images

Product Department: Quality assurance, to ensure that products are produced according to customer

requirements. Periodic checks and inspections are performed on each process.

Design Department: Experienced engineers provide design support in terms of structure and materials.

Sample Department: Provide free samples

within a certain period of time for customers to check the quality before ordering.

Inspection Department: A professional team inspects all products before shipment to ensure that the final

delivered products are free from defects or blemishes.

After-sales service: A professional service team is on call at any time to provide solutions and suggestions on product use and maintenance for customers' after-sales consultation.

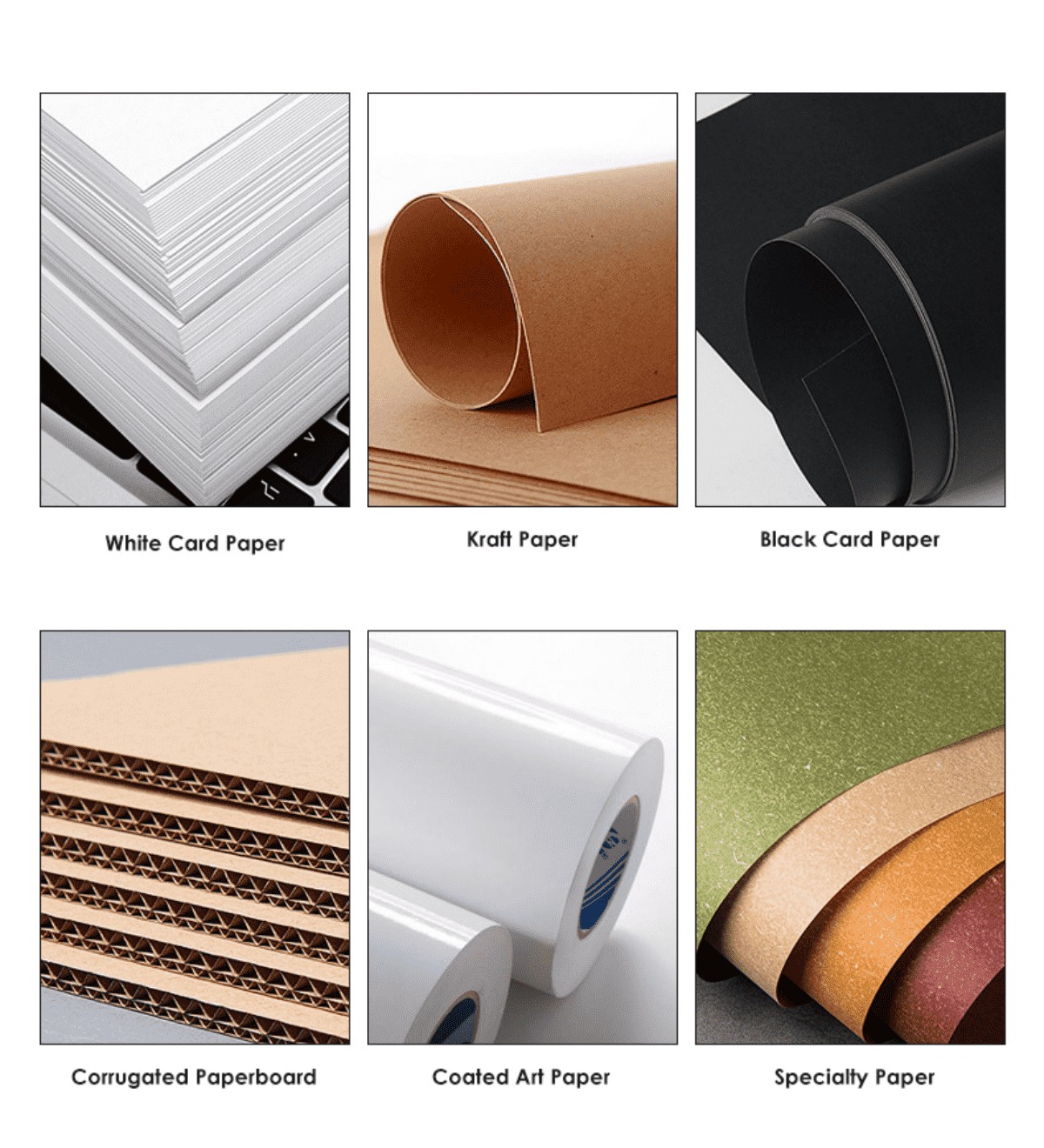

Material Structure and Application

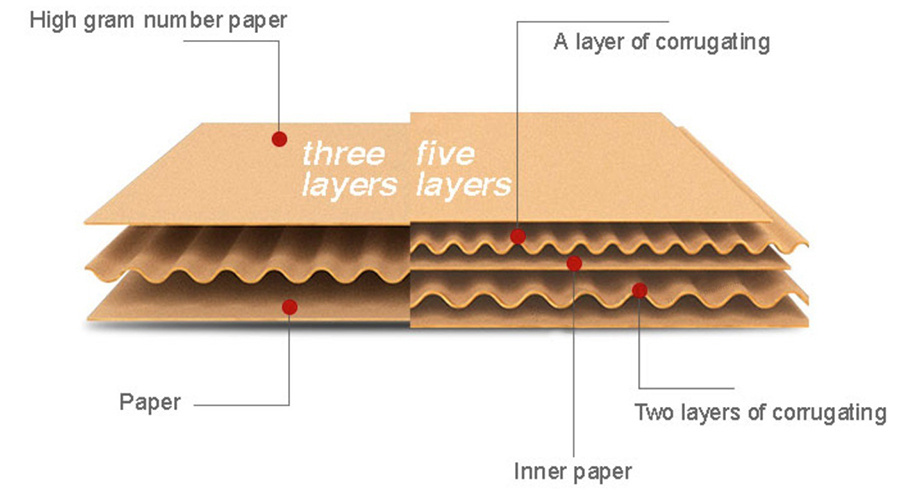

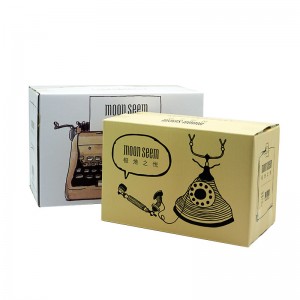

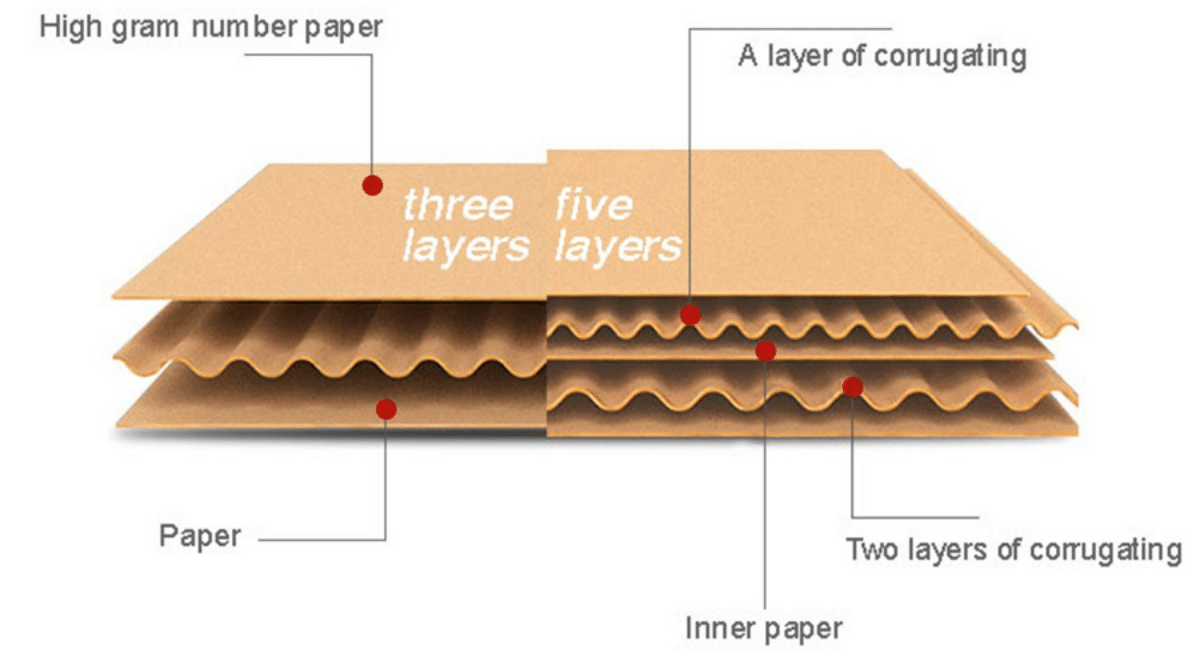

According to the combination structure, corrugated cardboard can be divided into 3layers, 5 layers and 7 layers, of which 3 layers and 5 layers are most commonly used, and 7 layers of cardboard are used for heavy packaging.

After printing and surface treatment, the outer paper is adhered to the corrugated board, and then die-cut to form a color printing carton. The external paper is patterned paper.

The variety of corrugated board and outer paper can be changed according to specific requirements.

Corrugated board

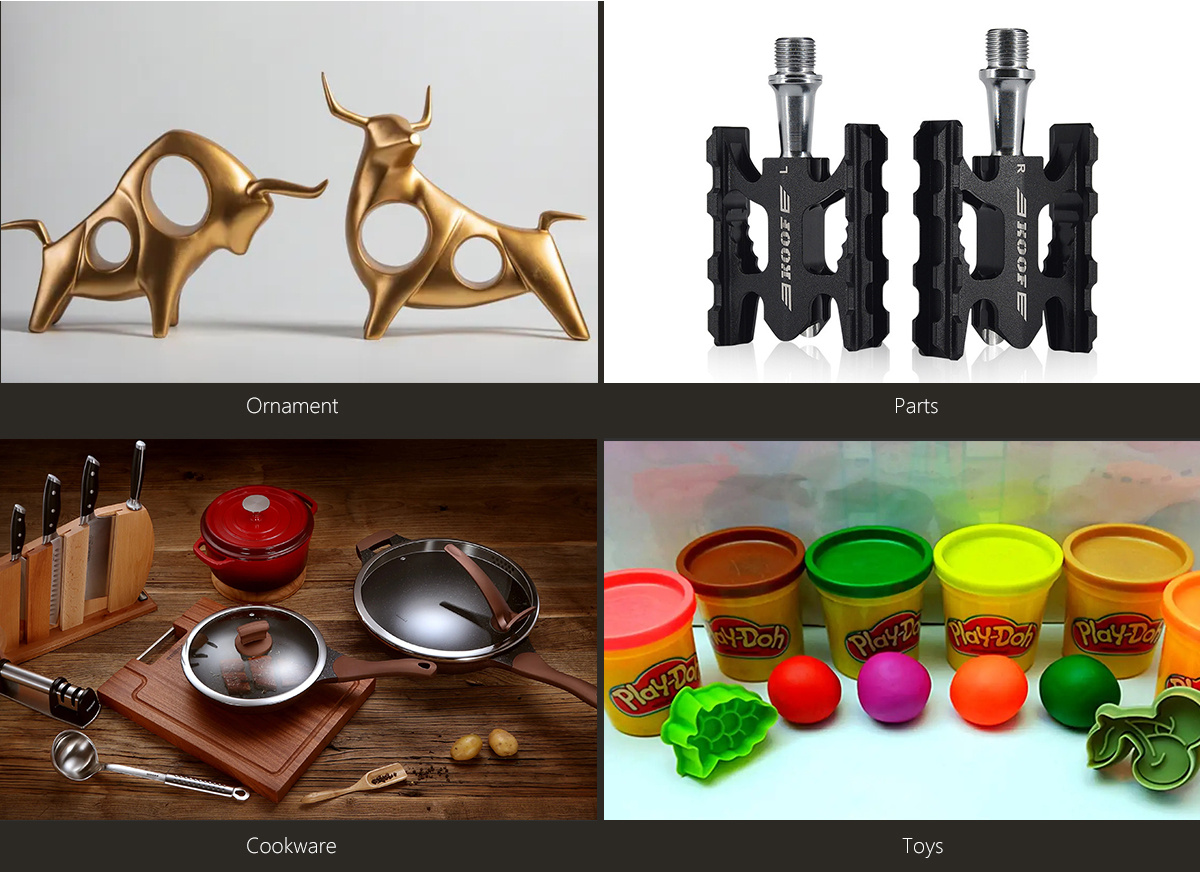

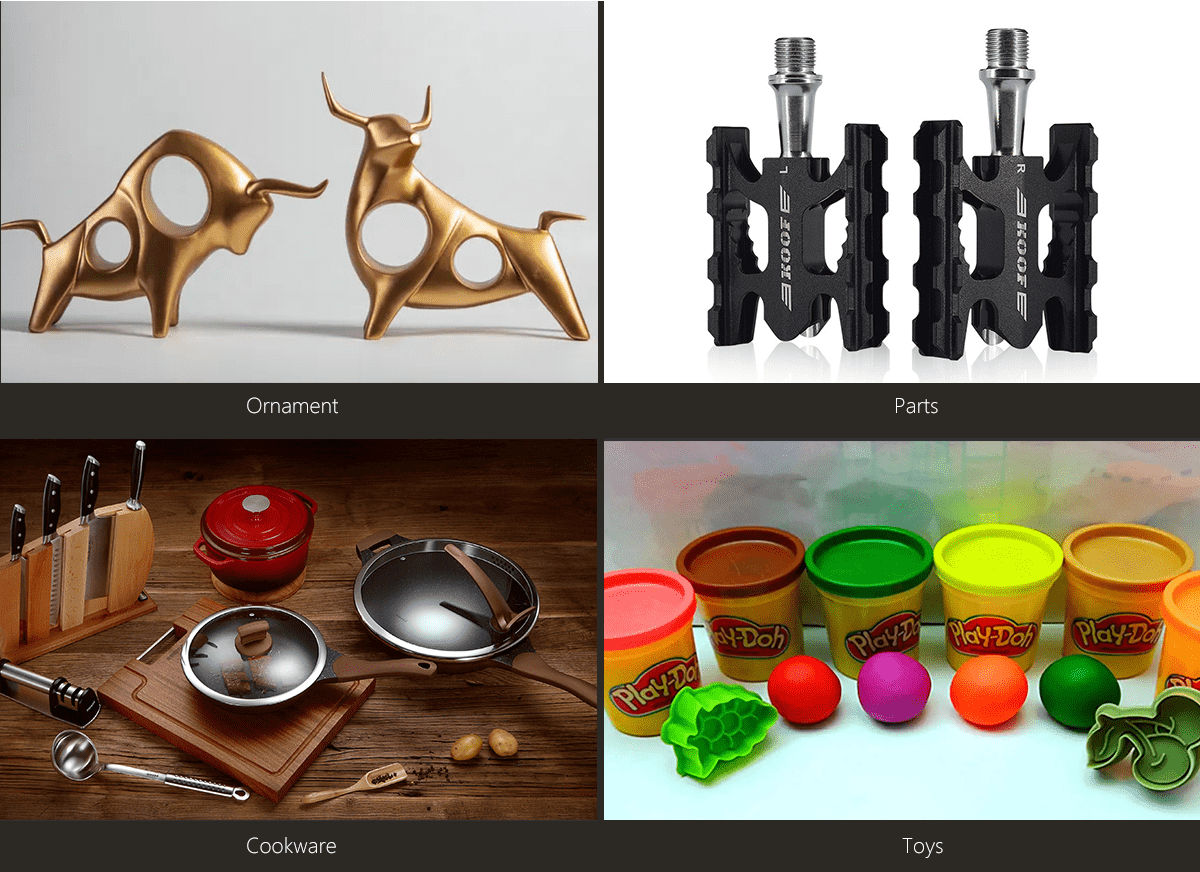

Packaging Applications

According to the combination structure, corrugated cardboard can be divided into 3layers, 5 layers and 7 layers, of which 3 layers and 5 layers are most commonly used, and 7 layers of cardboard are used for heavy packaging.

After printing and surface treatment, the outer paper is adhered to the corrugated board, and then die-cut to form a color printing carton. The external paper is patterned paper.

The variety of corrugated board and outer paper can be changed according to specific requirements.

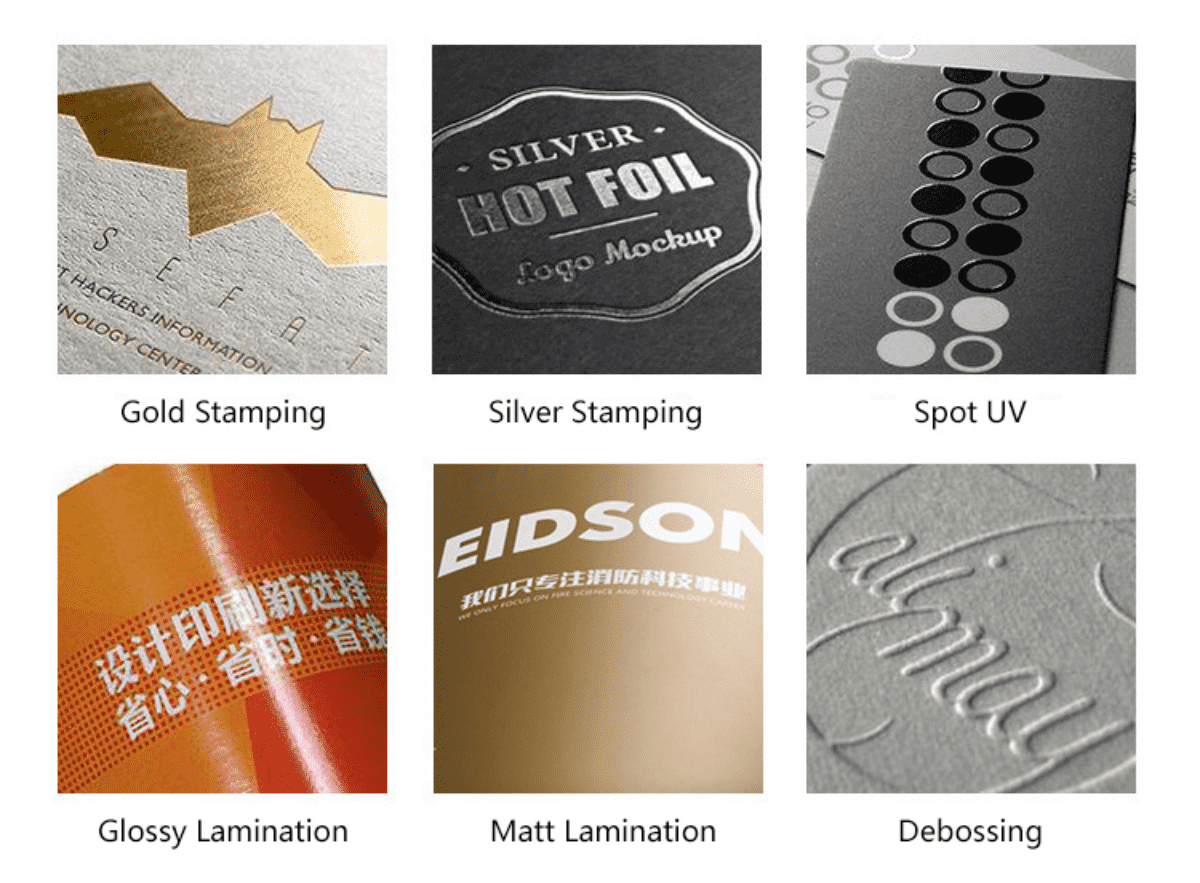

Box Type and Finish Surface

The box type as follow

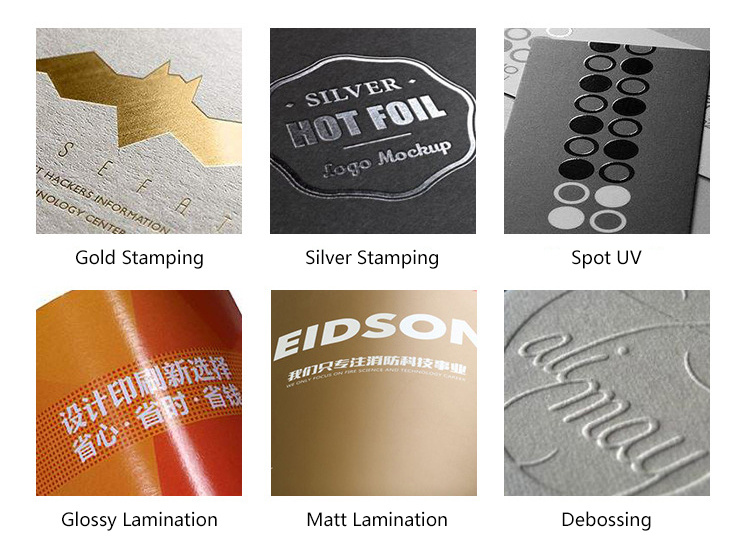

Surface Finishing

Printing surface treatments give printed products their unique look, allowing them to grab attention. In the market, Matt Lamination, Gloss Lamination, Hot Stamping, Hot Silver, Spot UV and Embossing are currently the most popular printing surface treatment technologies. These technologies can be used to directly print graphics or text on promotional slogans, and can also be used to change the overall decorative style of the housing.

Different surface treatment methods will cause different effects:

1.Matte film: black/white/envelope/snow white/orange peel/star;

2.Laminated film: high gloss/thickness 0.03mm;

3.Bronzing: crystal gold/good gloss/good permanence;

4.Hot silver: shining like crystal sand / natural smell / making it born;

5.Spot UV: Super large UV processing area-4*5cm, high contrast, strong three-dimensional effect;

6.Concave-convex: 3D three-dimensional 'physical' effect, attracting eyeballs;

As a novice, if you want to choose the correct surface treatment method and achieve good results:

1)you must first make a budget carefully and choose the appropriate method according to the situation;

2)seek help from industry experts if necessary;

3) try Do some mock tests.In short, printing surface treatment is a magical knowledge; images, text or graphics can be imagined accordingly; different types of bionics can be used to present them instinctively.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

According to the combination structure, corrugated cardboard can be divided into 3layers, 5 layers and 7 layers, of which 3 layers and 5 layers are most commonly used, and 7 layers of cardboard are used for heavy packaging.

After printing and surface treatment, the outer paper is adhered to the corrugated board, and then die-cut to form a color printing carton. The external paper is patterned paper.

The variety of corrugated board and outer paper can be changed according to specific requirements.

Corrugated board

Packaging Applications

According to the combination structure, corrugated cardboard can be divided into 3layers, 5 layers and 7 layers, of which 3 layers and 5 layers are most commonly used, and 7 layers of cardboard are used for heavy packaging.

After printing and surface treatment, the outer paper is adhered to the corrugated board, and then die-cut to form a color printing carton. The external paper is patterned paper.

The variety of corrugated board and outer paper can be changed according to specific requirements.

The box type as follow

Surface Finishing

Printing surface treatments give printed products their unique look, allowing them to grab attention. In the market, Matt Lamination, Gloss Lamination, Hot Stamping, Hot Silver, Spot UV and Embossing are currently the most popular printing surface treatment technologies. These technologies can be used to directly print graphics or text on promotional slogans, and can also be used to change the overall decorative style of the housing.

Different surface treatment methods will cause different effects:

1.Matte film: black/white/envelope/snow white/orange peel/star;

2.Laminated film: high gloss/thickness 0.03mm;

3.Bronzing: crystal gold/good gloss/good permanence;

4.Hot silver: shining like crystal sand / natural smell / making it born;

5.Spot UV: Super large UV processing area-4*5cm, high contrast, strong three-dimensional effect;

6.Concave-convex: 3D three-dimensional ‘physical’ effect, attracting eyeballs;

As a novice, if you want to choose the correct surface treatment method and achieve good results:

1)you must first make a budget carefully and choose the appropriate method according to the situation;

2)seek help from industry experts if necessary;

3) try Do some mock tests.In short, printing surface treatment is a magical knowledge; images, text or graphics can be imagined accordingly; different types of bionics can be used to present them instinctively.