Environmental friendly Recyclable materials 400gsm White Paper with Tear Line Mask Box

Description

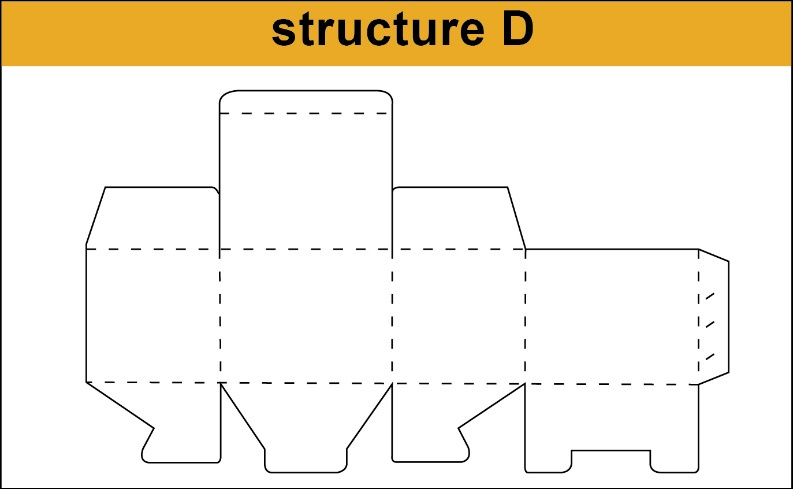

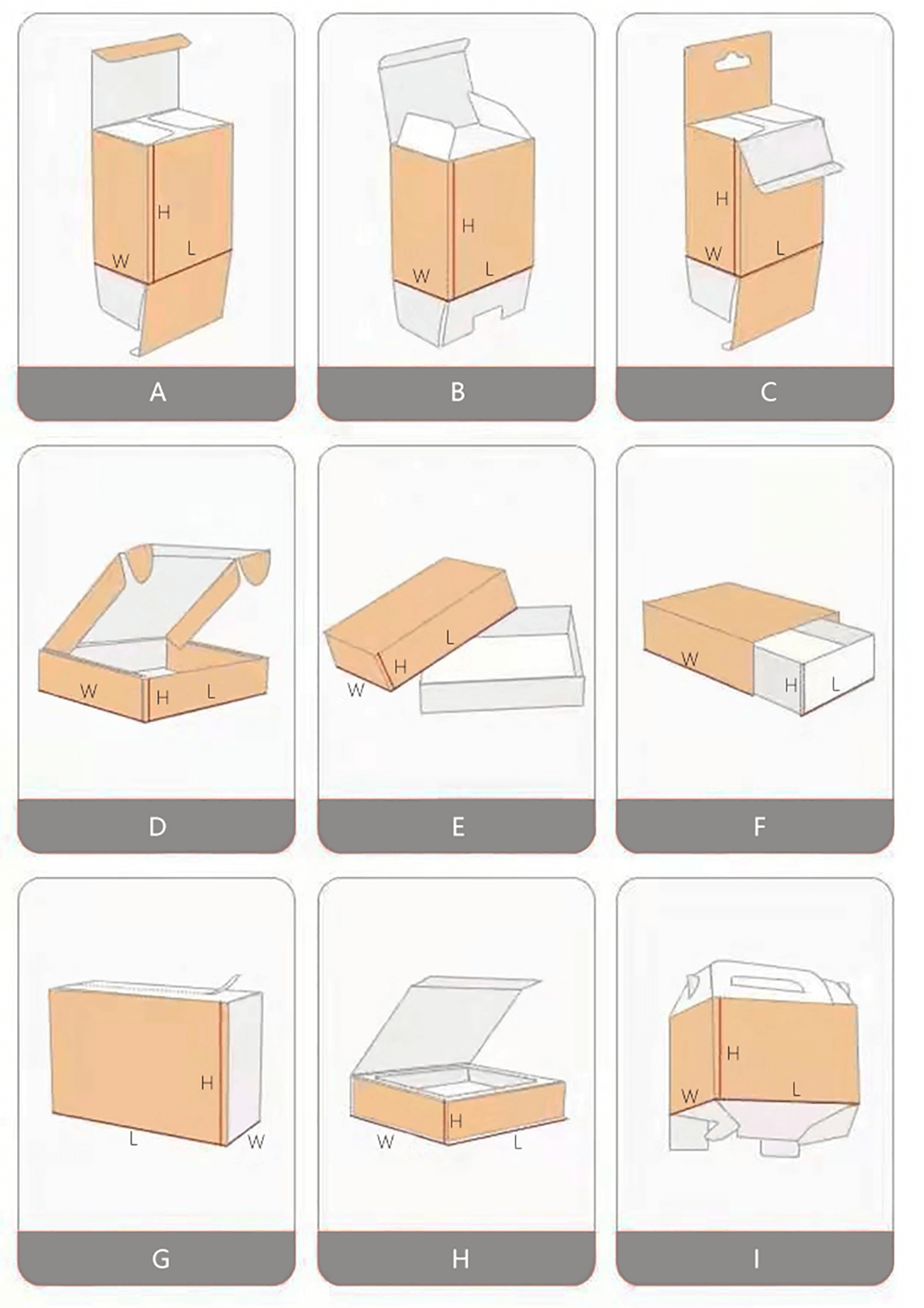

Structure D with tear lines on the top lid.

Offset printing outside, offer OEM design.

200/250/300/350/400gsm kraft paper for different size and product weight

Usually using on display shelf and show box.

Basic Info.

|

Product Name |

Color paper Box |

Surface Handling |

Glossy Lamination/Matte lamination |

|

Box Style |

Structure D |

Logo Printing |

Customized Logo |

|

Material Structure |

250 /300/350/400/500 gsm ivory board |

Origin |

Ningbo |

|

Weight |

75 gram weight |

Sample |

Accept custom samples |

|

Rectangle |

Rectangle |

Sample Time |

5-8 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

8-12 working days based on quantity |

|

Printing |

Offset Printing |

Transport Package |

Strong 5 ply Corrugated Carton |

|

Type |

Single /Two-sided Printing Box |

MOQ |

2000PCS |

Package size per unit product:L190 ×W110×H90mm;;

Gross weight per unit product:75 gram weight

Detailed Images

Structure D with tear lines on top lid . Our designer product box based on your product size or external size you need by wealth experience.

Material Structure and Application

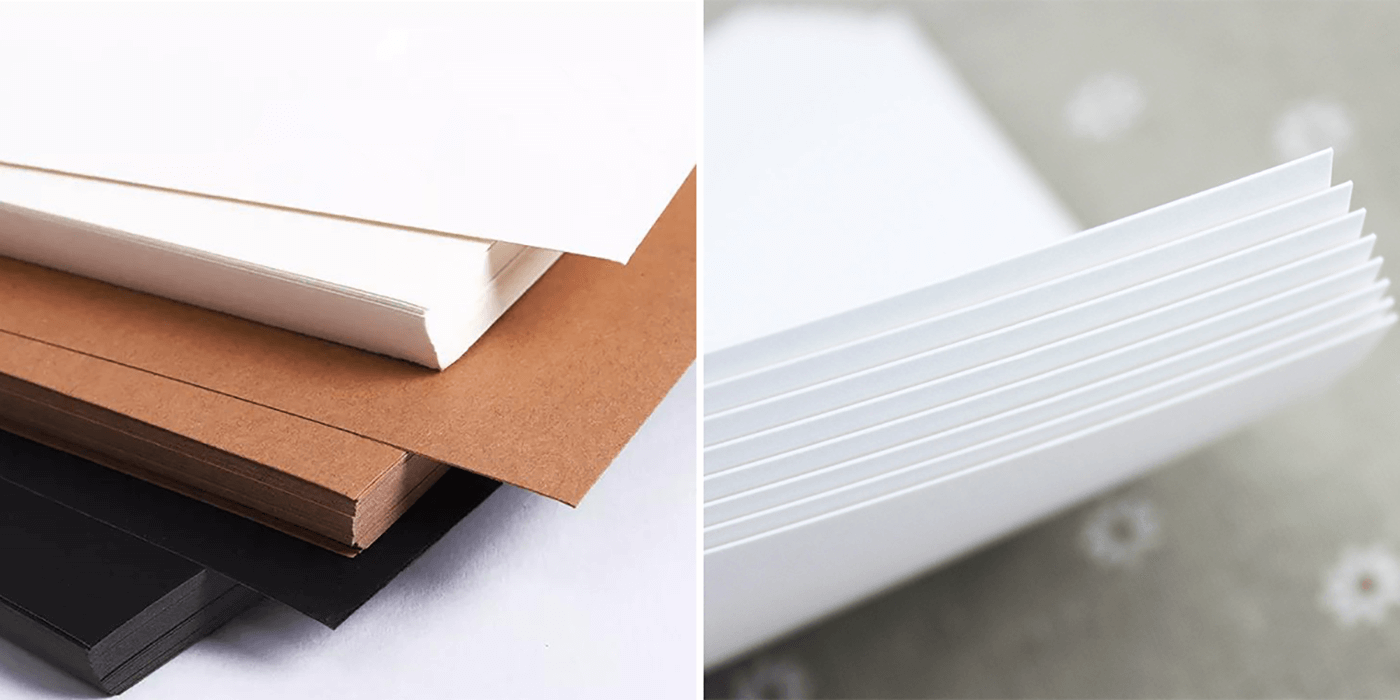

The thickness of white card paper is divided into 200gr, 250gr, 300gr, 350gr and 400gr.

Packaging Applications

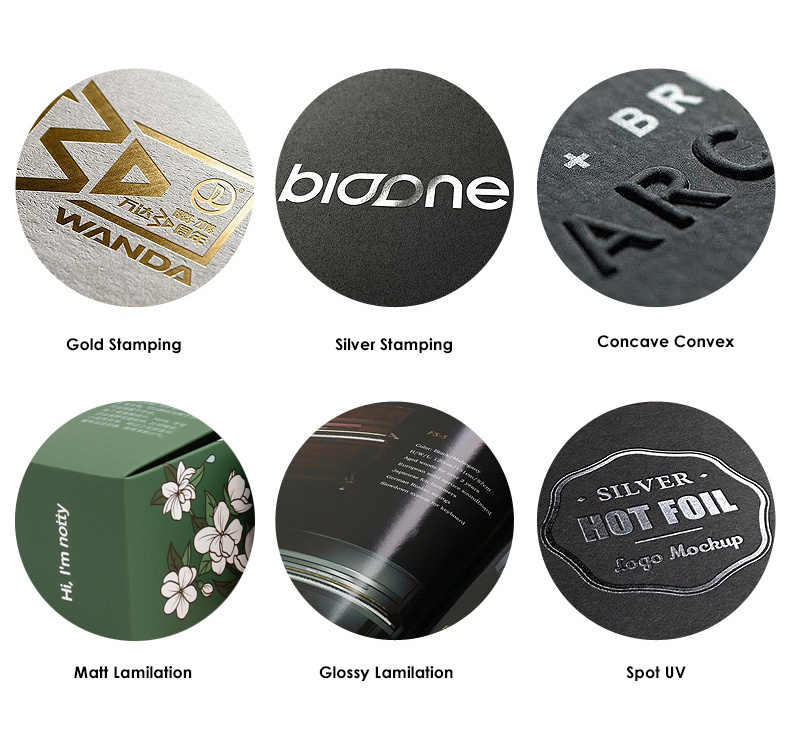

Box Type and Finish Surface

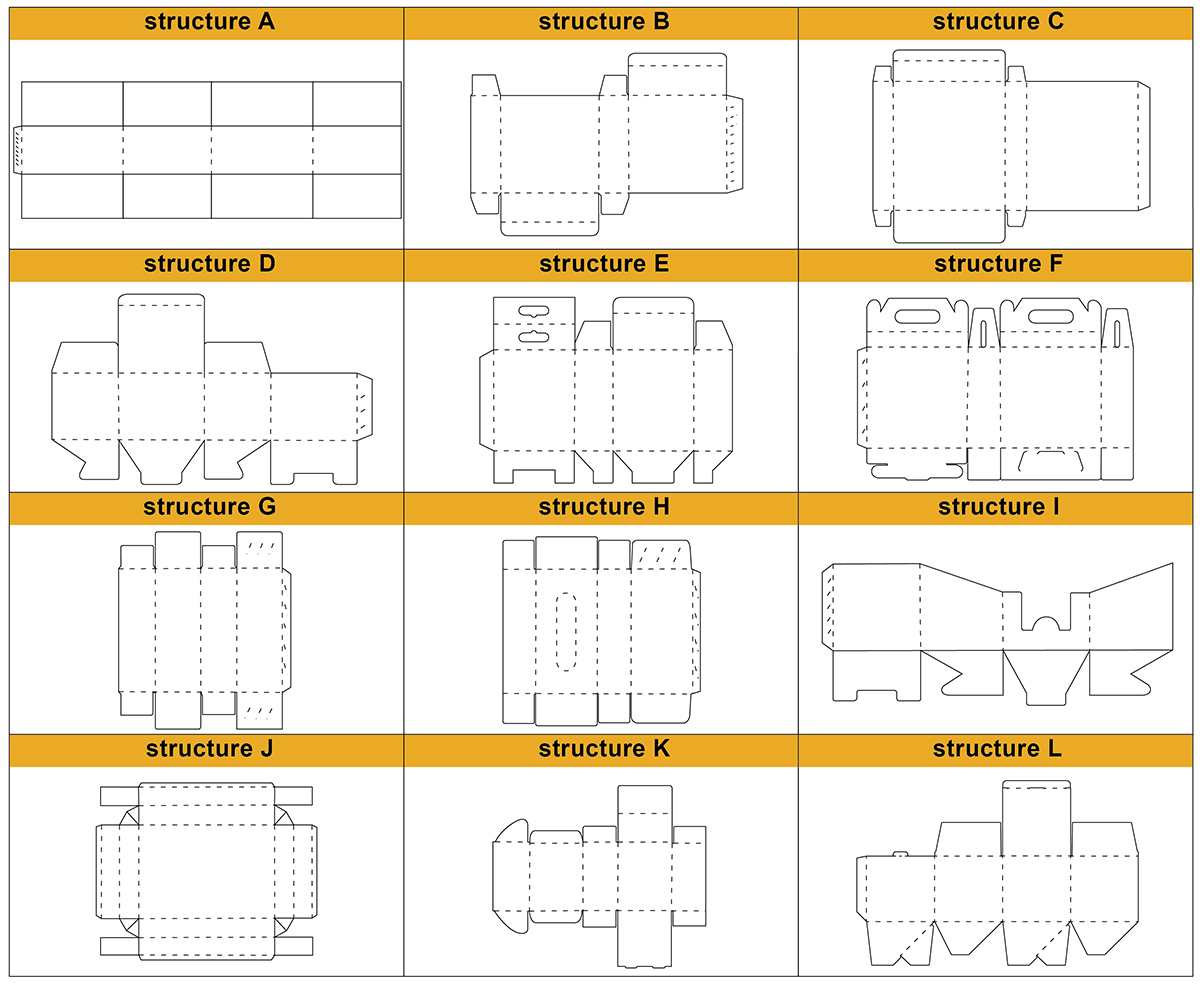

The box type as follow

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment as Follows

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Black Card Paper

Black cardboard is colored cardboard. According to different colors, it can be divided into red card paper, green card paper, etc. Its biggest drawback is that it can not print color, but it can be used for bronzing and silver stamping. The most commonly used is white card.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for printing advanced picture books, calendars and books, etc.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Ⅰ Material Structure

Paper box, Paper carton

◆Paper carton is a three-dimensional shape, it is composed of a number of planes moving, stacking, folding, surrounded by a multi-faceted shape. The surface in three-dimensional construction plays the role of dividing space in space. The surface of different parts is cut, rotated and folded, and the surface obtained has different emotions. The composition of the carton display surface should pay attention to the connection between the display surface, side, top and bottom, and the setting of the packaging information elements.

◆To a large extent, paper box packaging is based on its exquisite shape and decoration to promote the beautification of goods and improve the competitiveness of goods. Because the shape and structure design of the carton is often determined by the shape characteristics of the packaged goods, so its style and type are many. There are rectangular, square, multilateral, special carton, cylindrical, etc., but the manufacturing process is basically the same, that is, the selection of materials – design ICONS – manufacturing templates – stamping – synthetic box.

◆Common facial paper material

①Coated paper-C2S

Coated paper includes gray copper, white copper, single copper, gorgeous card, gold card, platinum card, silver card, laser card, etc.

•White board

White board divides into one side coated and double sides coated.

Similarity: both sides are white.

Difference: One side coated with single side printed;

Double sides -both sides have coating surface, both sides can be printed.

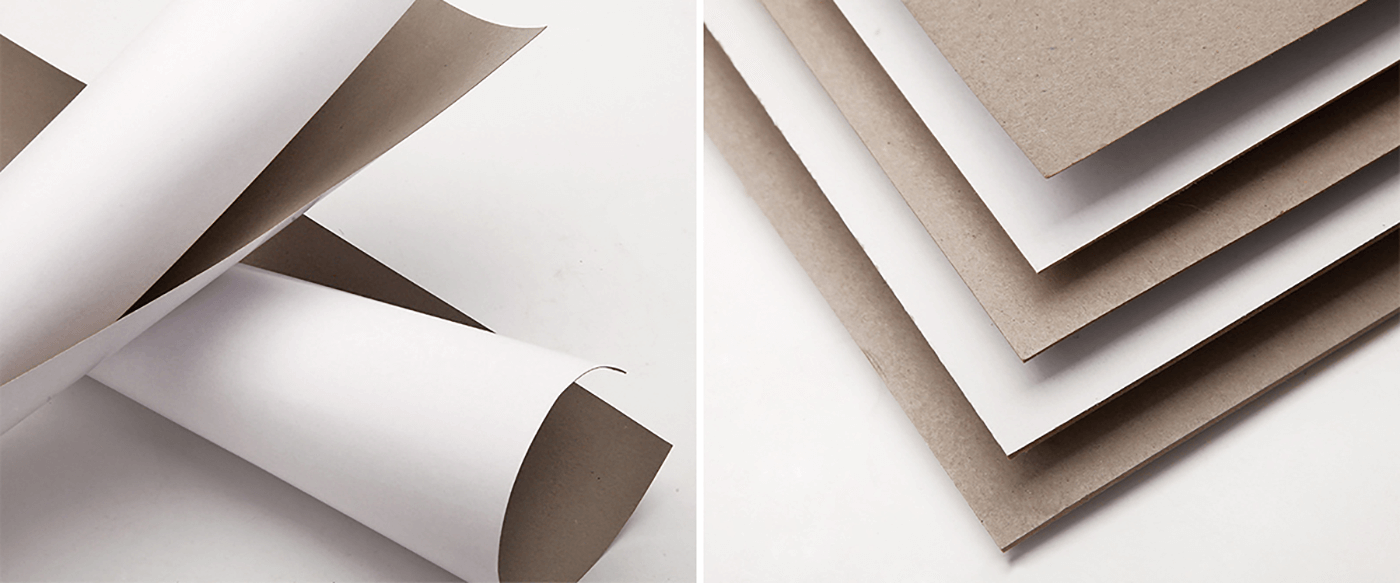

②White Greyboard

White greyboard paper is divided into grey white board and grey board. Gray bottom gray plate: do not print in the box manufacturer.

•Gray white board,Powder board paper, grey card paper, single-side white it is the so-called “powder gray paper”, that is, the front is white, can be printed, the back is gray, can not be printed.This kind of box cost is relatively low.

•White card paper

White card paper is better, the price is a little expensive, but the texture and hardness are enough, again the point is white (white board).

Powder board paper: white on one side, grey on the other, lower price.

•Double pink paper: white on both sides, high price.

•Laser card, Holographic paper

After printing with a kind of laser PVC material. There is a feeling of gold flashing from different angles. At the same time, you can also hot laser silver or laser gold on the surface of ordinary PVC card. When taking out the card to others, it can also improve the image of the enterprise and give people a feeling of nobility and elegance.

③ Specialty paper

Suitable for a variety of different demand effects of special paper: filled paper series, velvet series, gift packaging series, two-color pearlescent series, two-color bright face series, bright face series, wrapping paper series, matte wood black card series, original color card series, Lishi sealing paper series.

Ⅱ. Application Scenarios

◆ Paper box is especially commonly used with printed on the outside of the box.It is variety of exquisite patterns, very beautiful, attract the eyes of consumers;

The thinner carton is used for the outer packaging box of medicine, the weight is more light,such as tea, coffee, toy, etc. Which is very familiar to us in ordinary.

Paper box is also used for gift packaging box. Ivory board card box in the shape of the design is very flexible. It can be designed according to the shape of the product and the positioning of the product more reasonable packaging.

Ⅰ. Box Type

◆Packaging design of Paper Card Box

Packaging structure design can also play a decisive role in the sale of goods. An excellent packaging structure not only better display goods,but also bring convenience to consumers.

◆Commonly used paper card box packaging structure designs

•First, jack type carton packaging structure design

It is the most simple shape, simple process, low cost.

•Second, open window box packaging structure design

This form is used in toys, food and other products. The characteristic of this structure is that it can make the consumer to the product at a glance and increase the credibility of the product. The general part of the window is supplemented with transparent materials.

•Third, portable carton packaging structure design

It most used in gift box packaging, which is characterized by ease of carrying. However, we should pay attention to whether the volume, weight, material and handle structure of the product are comparable, so as to avoid consumer damage when using.

◆ Various shape of paper card boxes

Ⅱ Surface Disposal

◆The role of surface treatment

❶ Protect the color of the carton surface

The color image is the most direct message delivered by the gift box. If the color is removed, faded and faded, it is easy to leave the impression of poor quality and cheap. With oil and pvc lamination can protect the color of the surface of the carton, and the print will not fade easily under the ultraviolet light.

❷ Waterproof effect

The paper box in the warehouse storage, water is easy to mold, rot. After light oil and finish, it is equivalent to forming a protective film on the surface paper. Which can isolate the water vapor outside and protect the product.

❸ Add texture to the box

Surface is smoother, feel more comfortable. Especially after the matte glue, to the carton surface increased a layer of fog, which is more upscale.

◆Common surface treatment effect