Factory Degradable Strong Packing Kraft Paper Corrugated Box with Window

Description

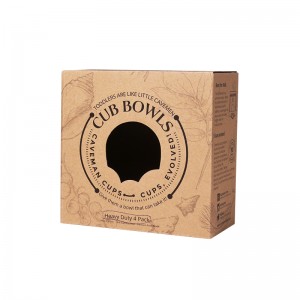

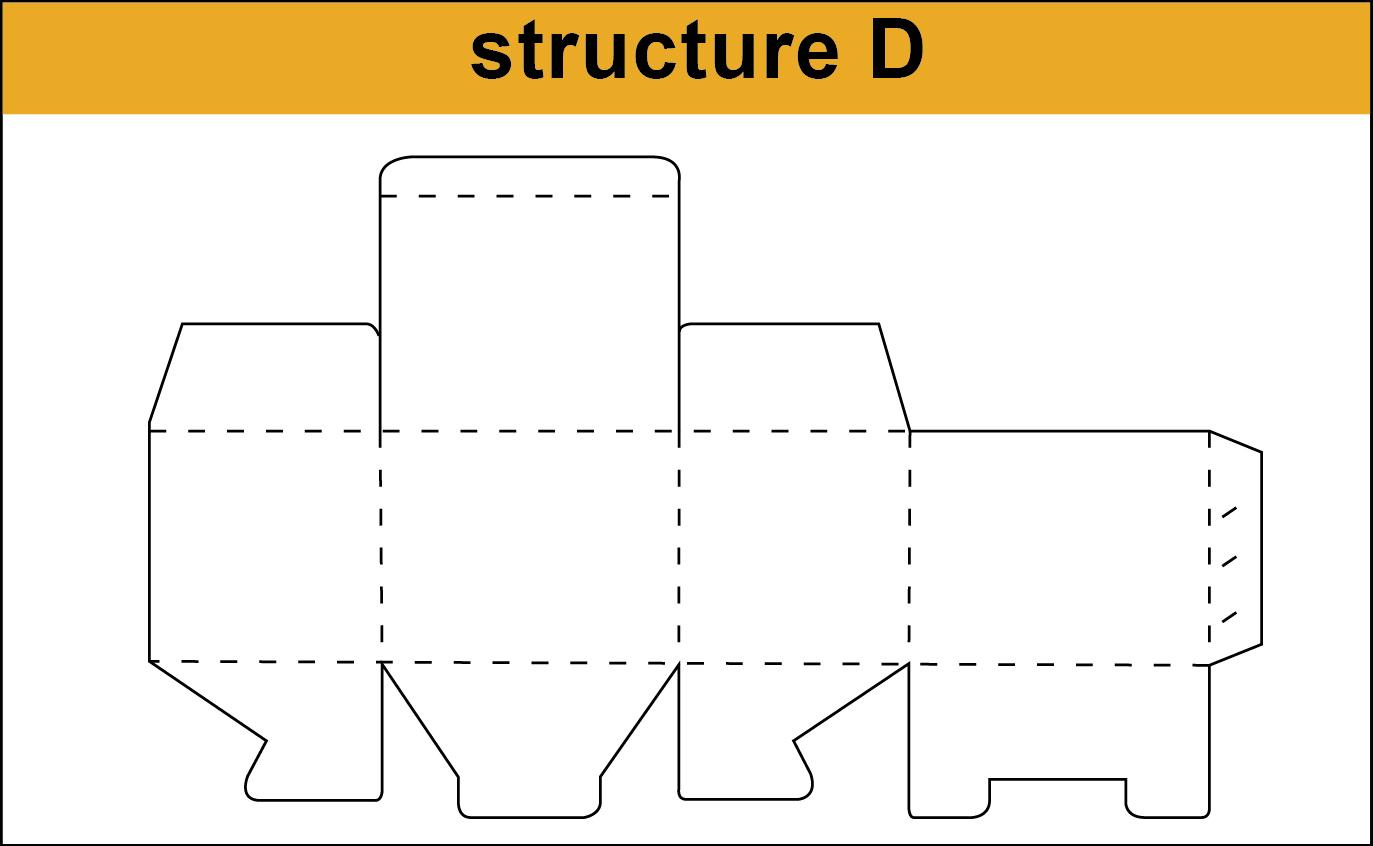

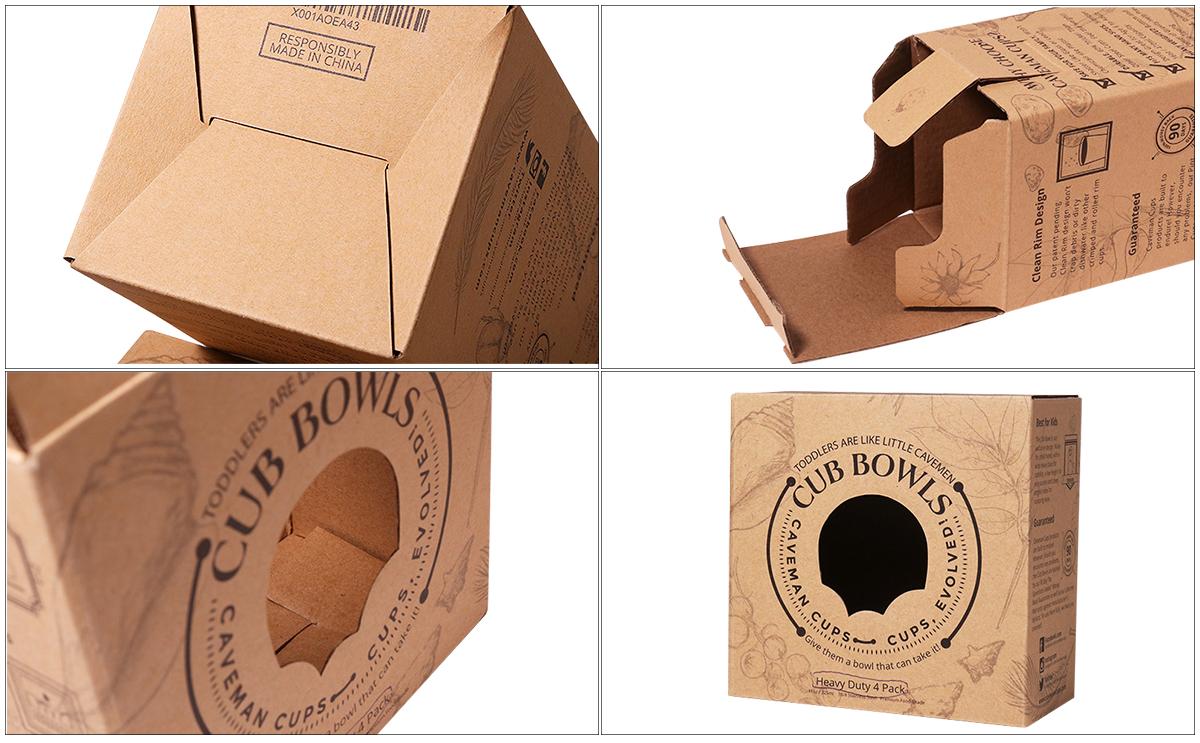

It is self-forming bottom structure with top whole opening way.

Natural and retro in appearance, kraft paper can be used for a variety of brands. Without sophisticated printing, a good visual impression can be achieved.

Basic Info

|

Product Name |

Recyclable Kraft Corrugated Box |

Surface Handling |

No Lamination |

|

Box Style |

OEM design |

Logo Printing |

Customized Logo |

|

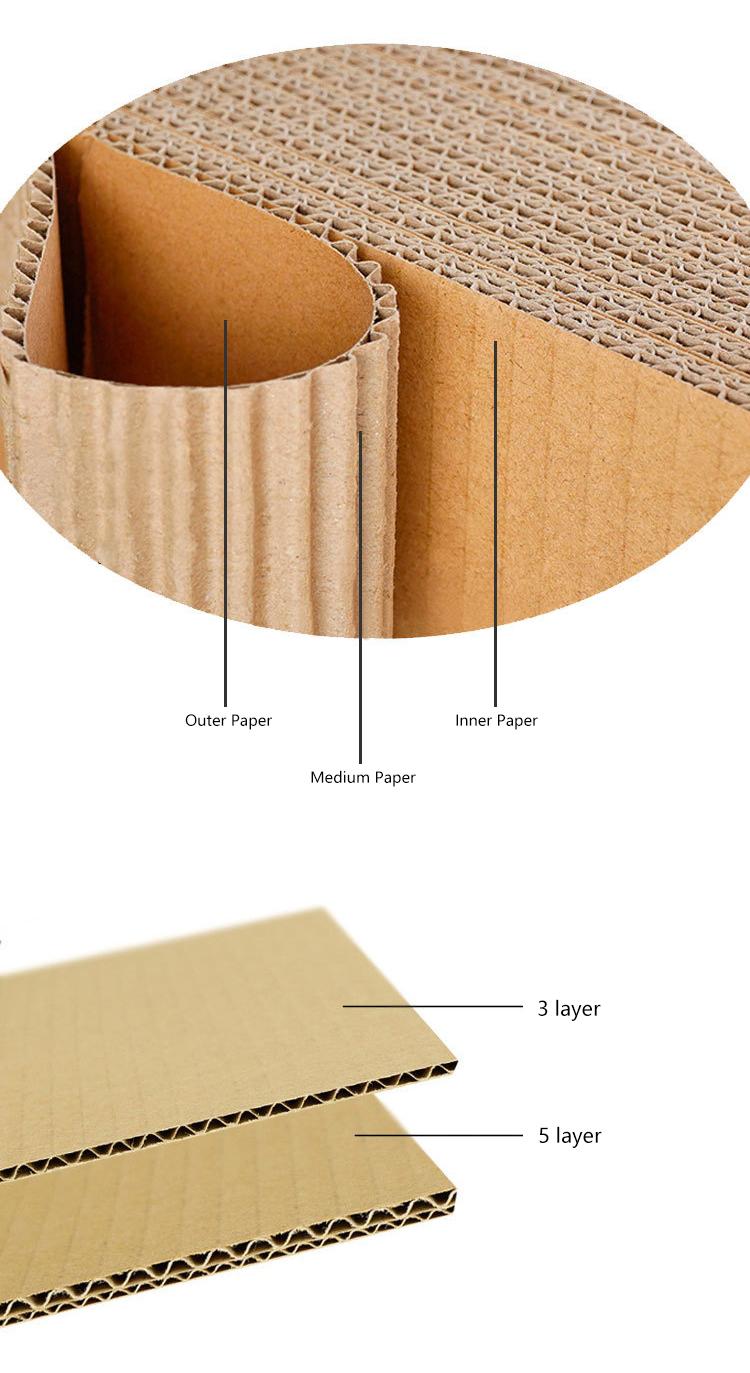

Material Structure |

Kraft paper + Corrugated Paper + Kraft Paper |

Origin |

Ningbo |

|

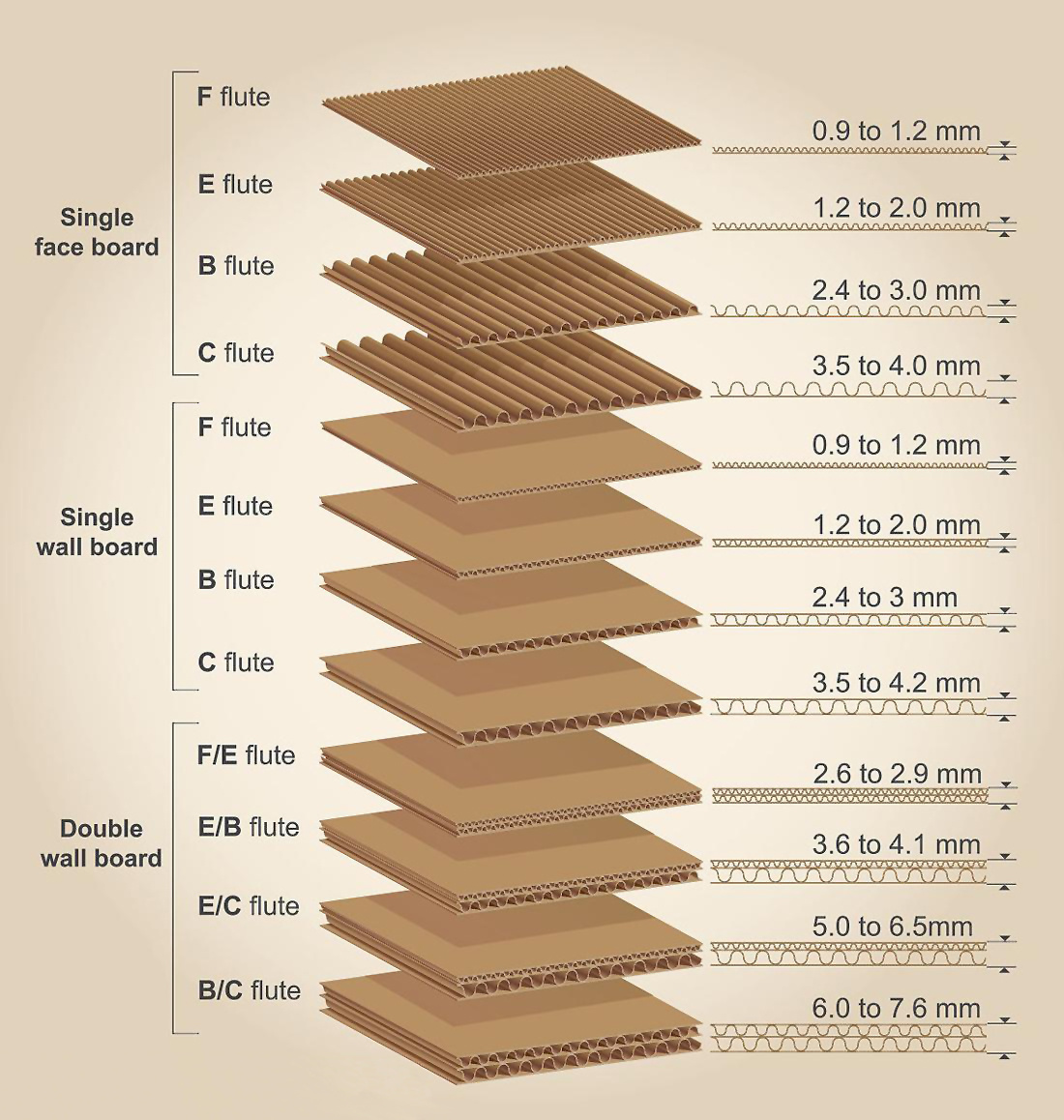

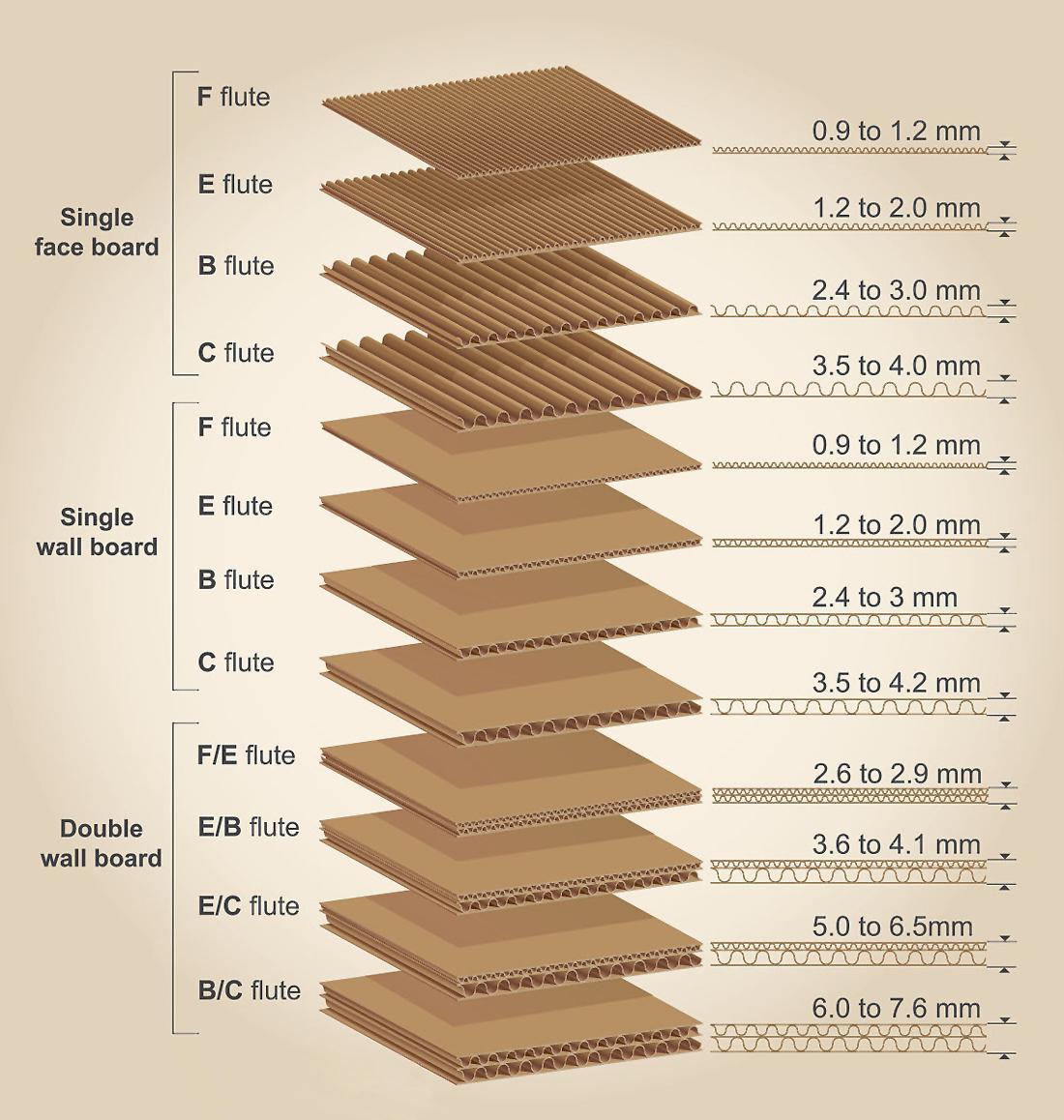

Flute Type |

E Flute, B Flute, C Flute, BE Flute |

Sample |

Accept custom samples |

|

Shape |

Rectangle |

Sample Time |

5-7 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

10-15 days based on quantity |

|

Printing |

Offset Printing, UV printing |

Transport Package |

Strong 5 ply Corrugated Carton |

|

Type |

Single Printing Box |

MOQ |

2000PCS |

Detailed Images

Flexographic printing kraft paper box is printed directly on kraft corrugated cardboard. The color is relatively simple and the price is low.

Offset printing kraft paper box needs to be printed on kraft paper first, and then mounted on kraft corrugated cardboard. This printing method has beautiful and rich colors.

Offset Printing Effect & Flexographic Printing Effect

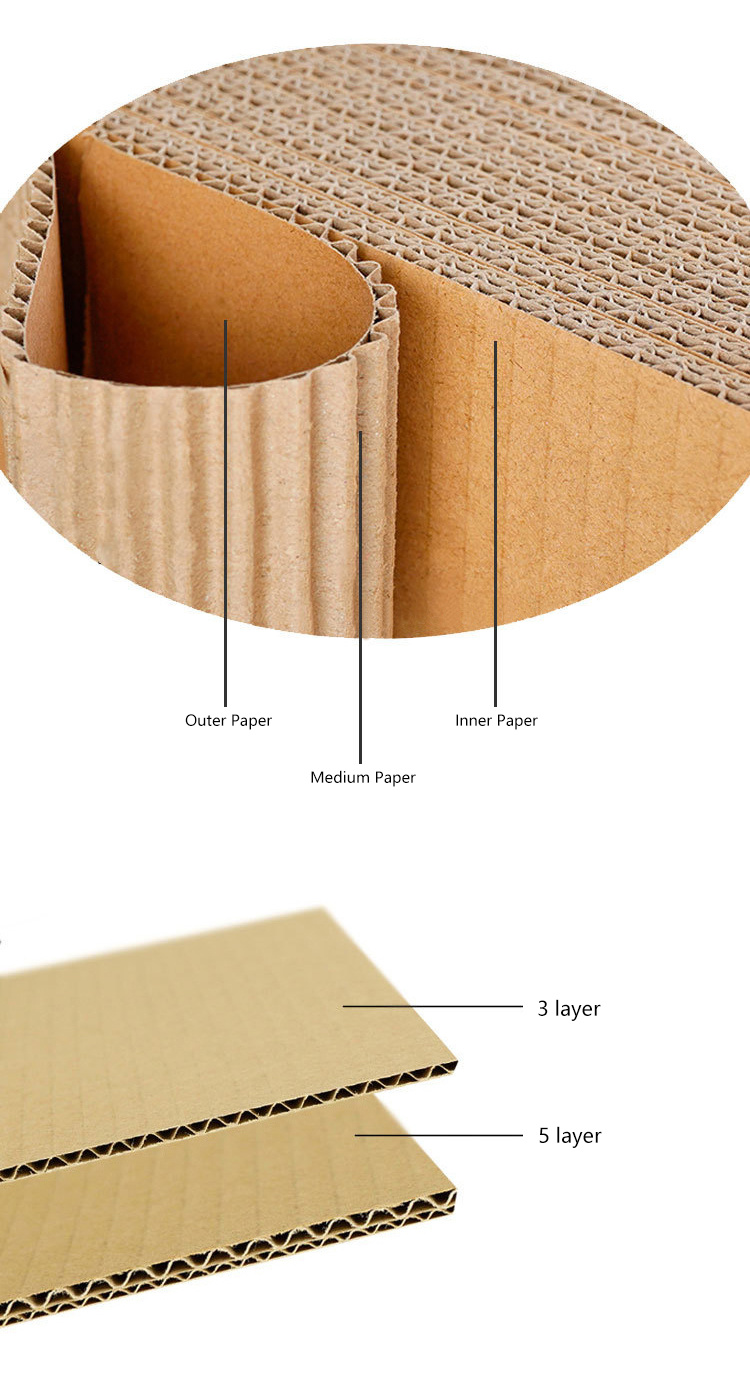

Material Structure and Application

Due to the good mechanical strength of corrugated cardboard, it can withstand collisions and falls during handling.

The actual performance of corrugated cardboard depends on three factors: the characteristics of core paper and cardboard and the structure of cardboard itself.

Kraft paper packaging has the following characteristics: high strength, low cost, good air permeability and crack resistance.

Corrugated Paperboard Structure Diagram

Application

Kraft paper is a robust and water-resistant packaging material that is frequently used in cartons, handbags, color boxes, wine boxes, gift boxes, document bags, and other industries.

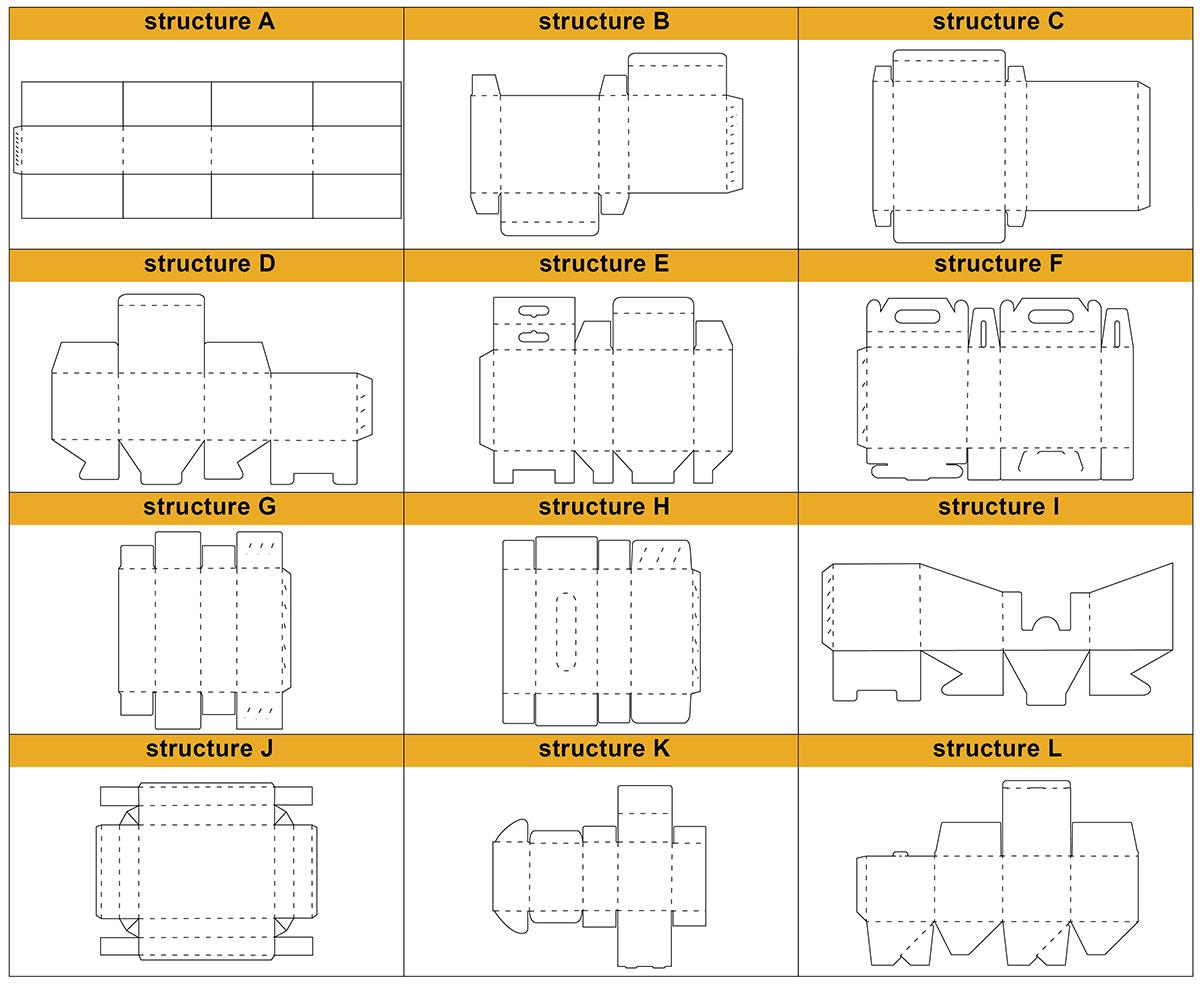

Box Type and Finish Surface

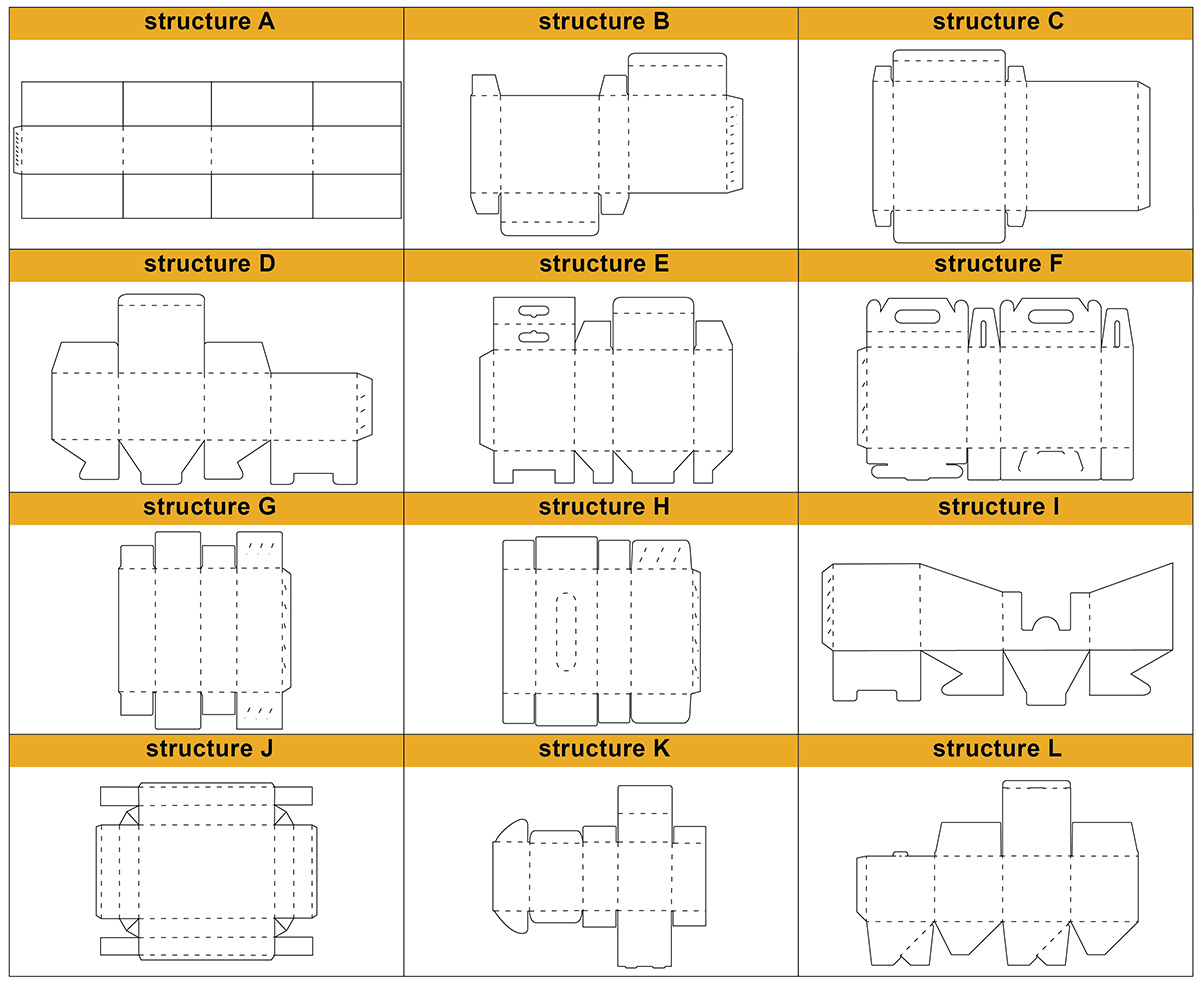

The box type as follow

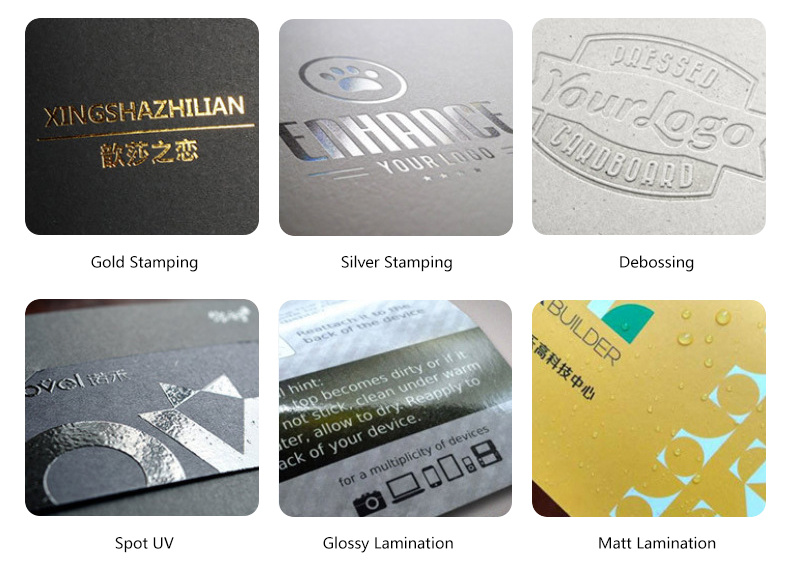

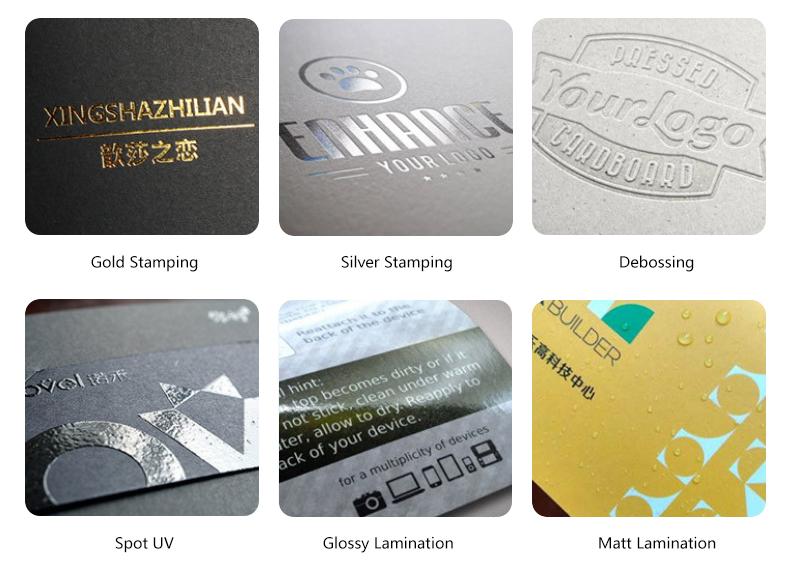

Surface treatment process

Foil Stamping

There are many kinds of foil stamping materials, including gold, silver, laser gold, laser silver, black, red, green, etc.

Lamination

Lamination process refers to using a film covering machine to cover the surface of printed matter with a layer of transparent plastic film.

Debossing

Concave and convex embossing is to use the greater pressure of the relief printing machine to roll the local patterns or characters on the printed semi-finished products into distinct concave and convex, three-dimensional images and characters.

Spot UV

Through UV drying and curing, the ink is bright and special, especially for trademarks, logos and local printing content.

Common Surface Treatment as Follows

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Due to the good mechanical strength of corrugated cardboard, it can withstand collisions and falls during handling.

The actual performance of corrugated cardboard depends on three factors: the characteristics of core paper and cardboard and the structure of cardboard itself.

Kraft paper packaging has the following characteristics: high strength, low cost, good air permeability and crack resistance.

Corrugated Paperboard Structure Diagram

Application

The box type as follow

Surface treatment process

Foil Stamping

There are many kinds of foil stamping materials, including gold, silver, laser gold, laser silver, black, red, green, etc.

Lamination

Lamination process refers to using a film covering machine to cover the surface of printed matter with a layer of transparent plastic film.

Debossing

Concave and convex embossing is to use the greater pressure of the relief printing machine to roll the local patterns or characters on the printed semi-finished products into distinct concave and convex, three-dimensional images and characters.

Spot UV

Through UV drying and curing, the ink is bright and special, especially for trademarks, logos and local printing content.

Common Surface Treatment as Follows