Logo Printed White design on Kraft Bio-Degradable brown Sleeve white corrugated packaging box Set for Cable with Windown

Description

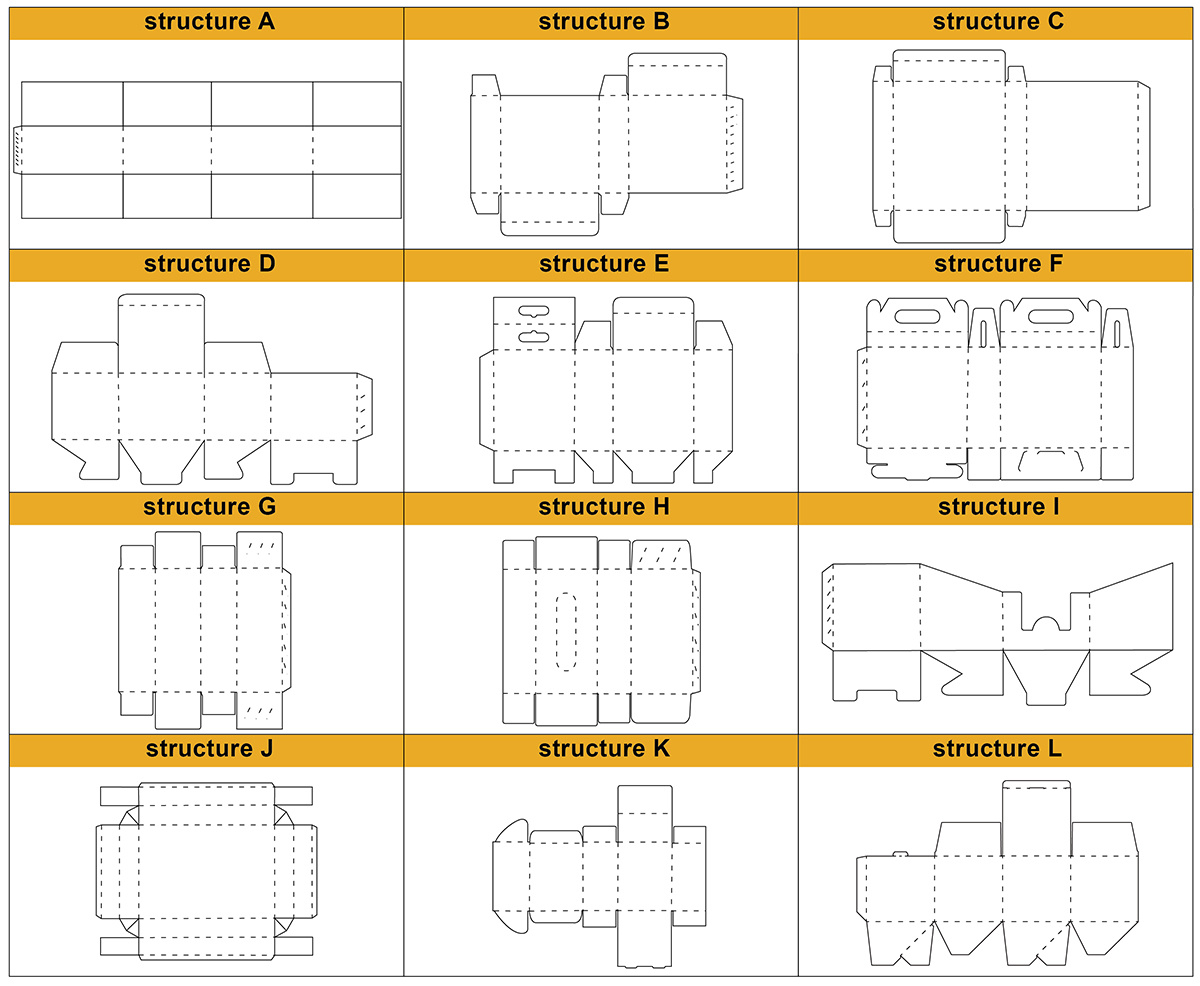

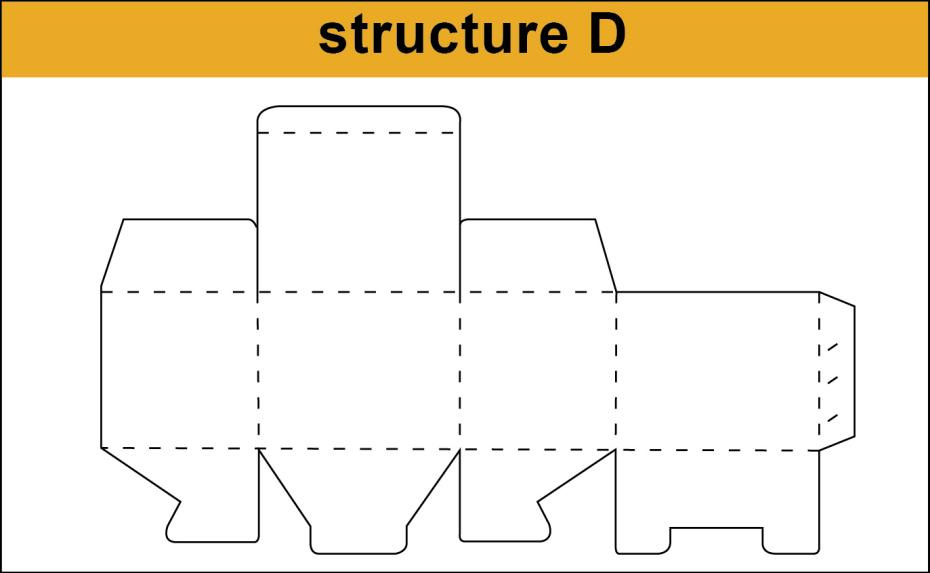

Component:one kraft paper sleeve + one white corrugated carton in structure D with paper hanging hole + one white corrugated board lining. All materials are 100% bio-degradable.

White UV printing on kraft paper without lamination;

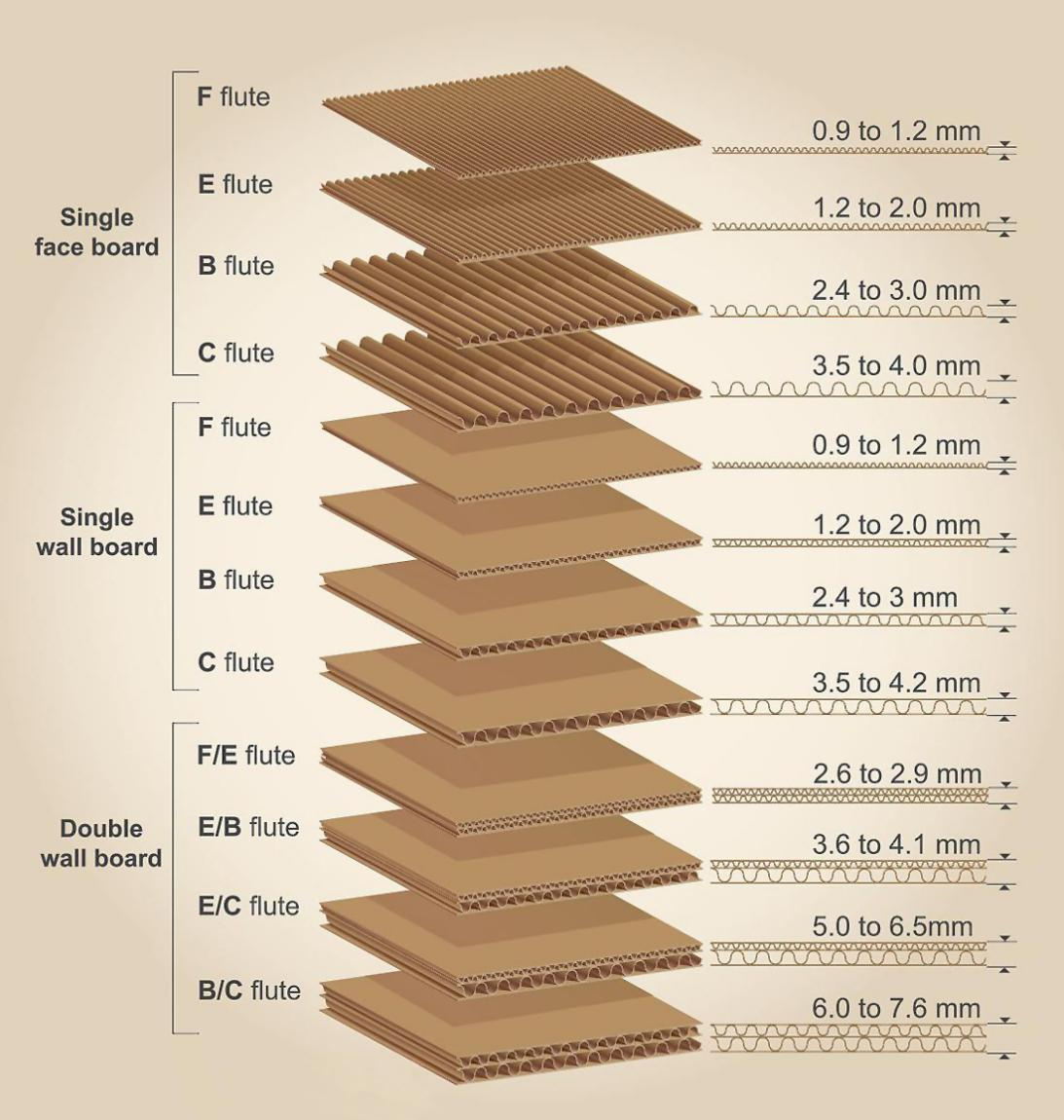

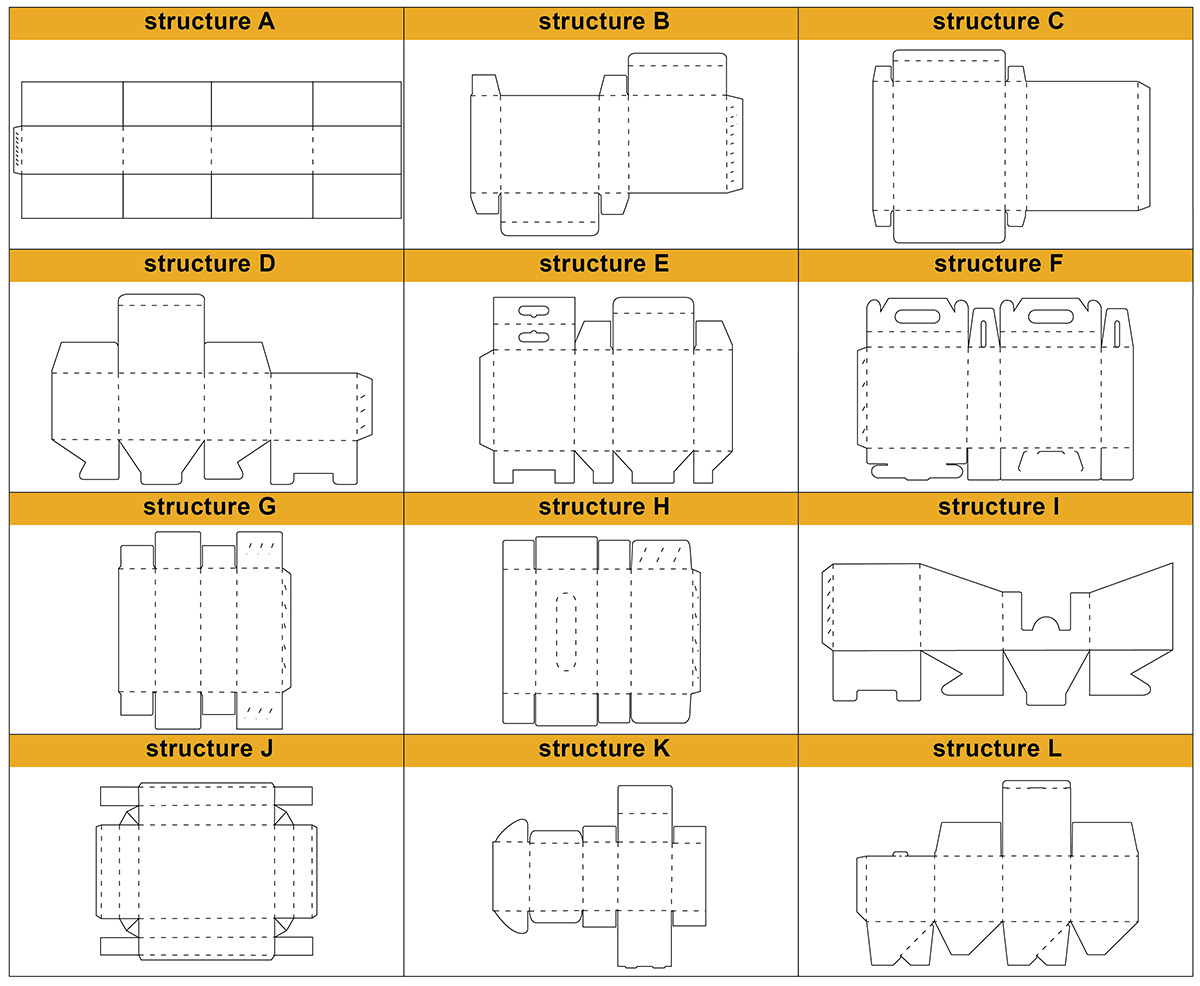

The material is strong corrugated paperboard in 3 ply/5 ply, to fit different weight and size of gift product. Enclosing structure D for your reference.

Basic Info

| Product Name | Sleeve & Corrugated Box set | Artwork version | AI, PDF, CAD. etc |

| Place of origin | Ningbo, China | MOQ | 2000 sets |

| Logo | accept customize | HS code | 4819200000; 4819100000 |

| Size | Customized size accept | Sample | Accept custom samples |

| Box Style | Sleeve+ corrugated carton+ board lining | Sample Time | 5-8 Working Days after confirmed files |

| Feature | Bio-degradable materials | Production Lead Time | 8-12 working days after confirmed files |

| Printing | UV Printing(white color on kraft paper) | Usage | Display box in supermarket; shipping carton |

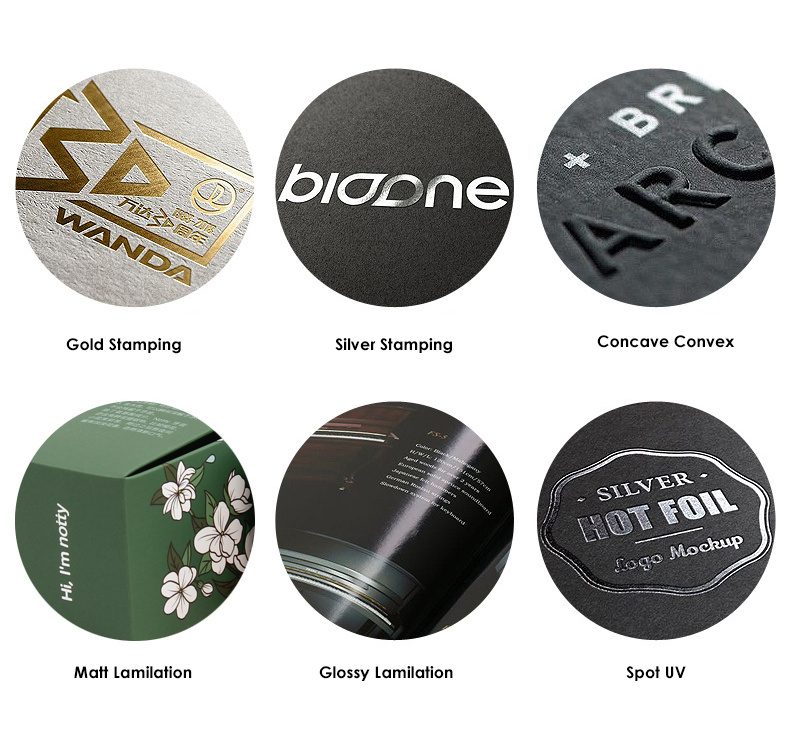

| Surface Handling | Embossing, no plastic lamination | Package | Use carton package |

Picture sample boxes data: Small box set- outer dimension 142 *95*141 mm;Big box set -outer dimension-140 *93*210 mm;

Gross weight per unit product:small box set -63.7 gram weight;big box set- 101.6 gram weight

Detailed Images

We have own professional team of designer , die lining,printing .They can adjust size in different thickness of materials to suited package box and lining. Sleeve, corrugated box and inside lining compatible together well. Please attach more details!

Material Structure and Application

Sleeve: kraft brown paper, white ivory board, art paper , etc.

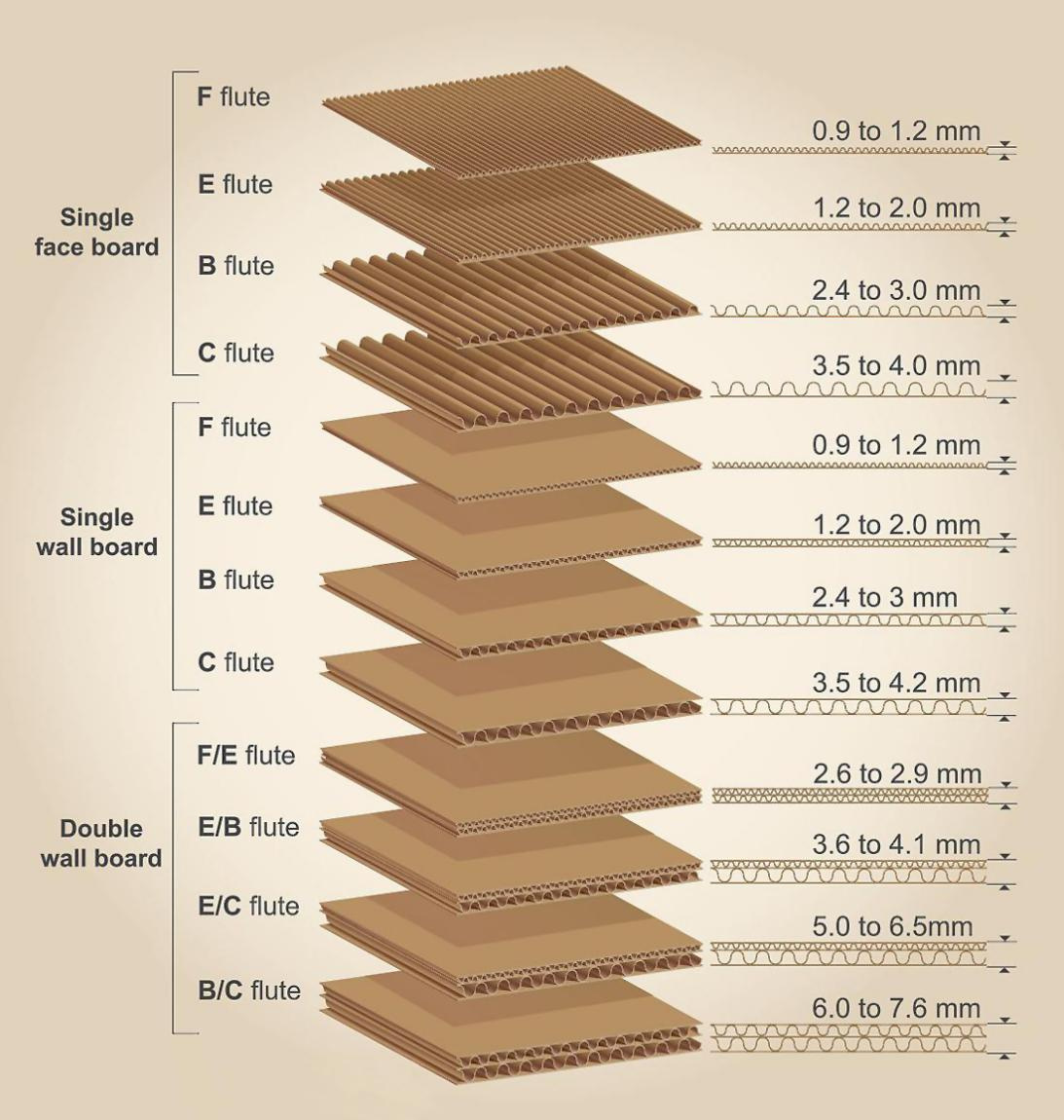

Corrugated box: white greyboard/kraft paper + corrugated board in flute;

cardboard lining: white greyboard /kraft paper+corrugated board in flute.Accept custom materials. Please attach more materials below:

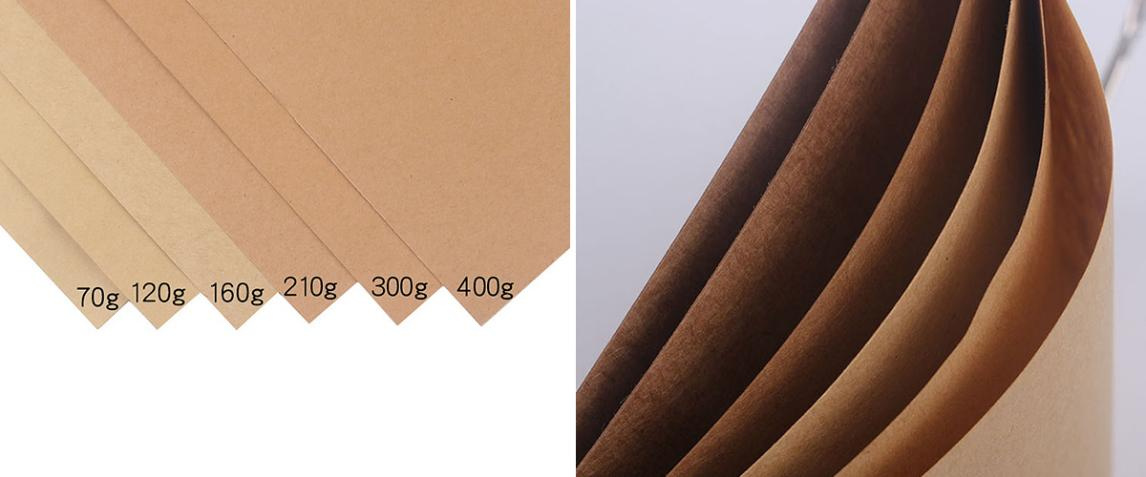

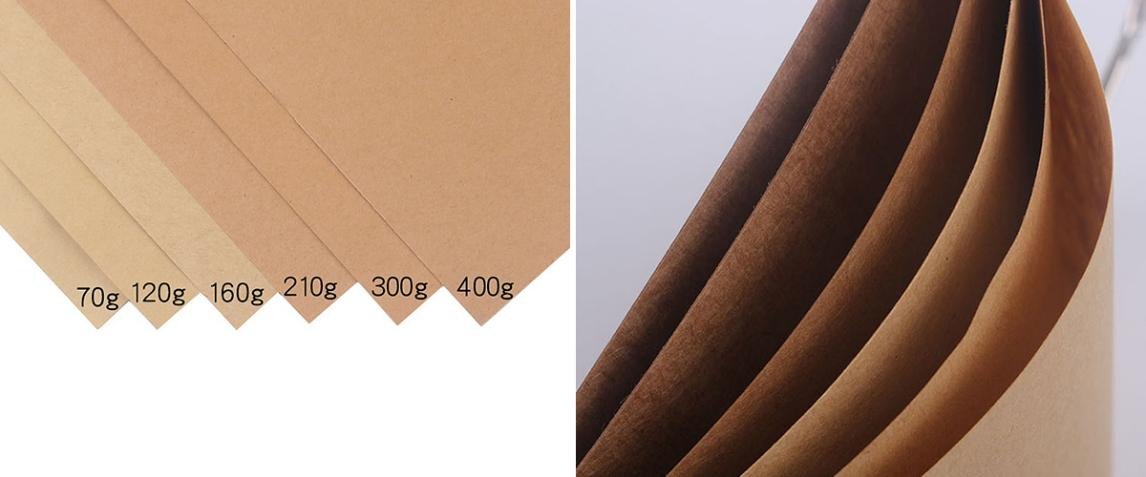

Different Paper Type

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for

printing advanced picture books, calendars and books, etc.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

Corrugated board type

Packaging Applications

Box Type and Finish Surface

The box type as follow

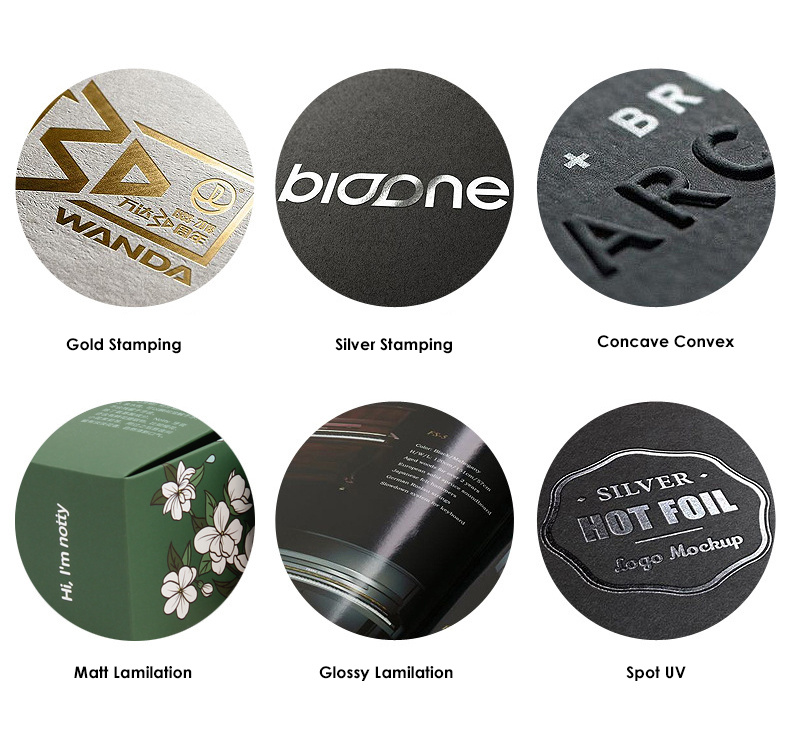

Surface Treatment

Generally speaking, color box packaging printing needs some special processing, such as gloss glue, dumb glue, gloss oil and so on. In general, it is based on the following factors:

1, protect the color of printed matter. The box paper is printed in ink. Under the action of ultraviolet light, it is easy to discolor printed matter.

2, waterproof effect is good, because the color box packaging is paper products, in order to prevent water rot;

Improve the brightness of the product, after special surface treatment, make the product soft, feel rough. More attractive to consumers.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Sleeve: kraft brown paper, white ivory board, art paper , etc.

Corrugated box: white greyboard/kraft paper + corrugated board in flute;

cardboard lining: white greyboard /kraft paper+corrugated board in flute.

Accept custom materials. Please attach more materials below:

Different Paper Type

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for

printing advanced picture books, calendars and books, etc.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

Corrugated board type

Packaging Applications

The box type as follow

Surface Treatment

Generally speaking, color box packaging printing needs some special processing, such as gloss glue, dumb glue, gloss oil and so on. In general, it is based on the following factors:

1, protect the color of printed matter. The box paper is printed in ink. Under the action of ultraviolet light, it is easy to discolor printed matter.

2, waterproof effect is good, because the color box packaging is paper products, in order to prevent water rot;

Improve the brightness of the product, after special surface treatment, make the product soft, feel rough. More attractive to consumers.