Luxury White Packaging Grey Paperboard Cover & Tray Classic Gift Cardboard Box for Sports Bracelet

Description

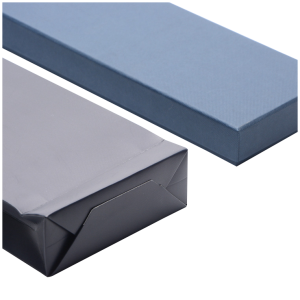

It is traditional classic paper gift with 2 mm gray board.

It can be OEM design of double offset printing paper or color art paper pasting outer and inside box.

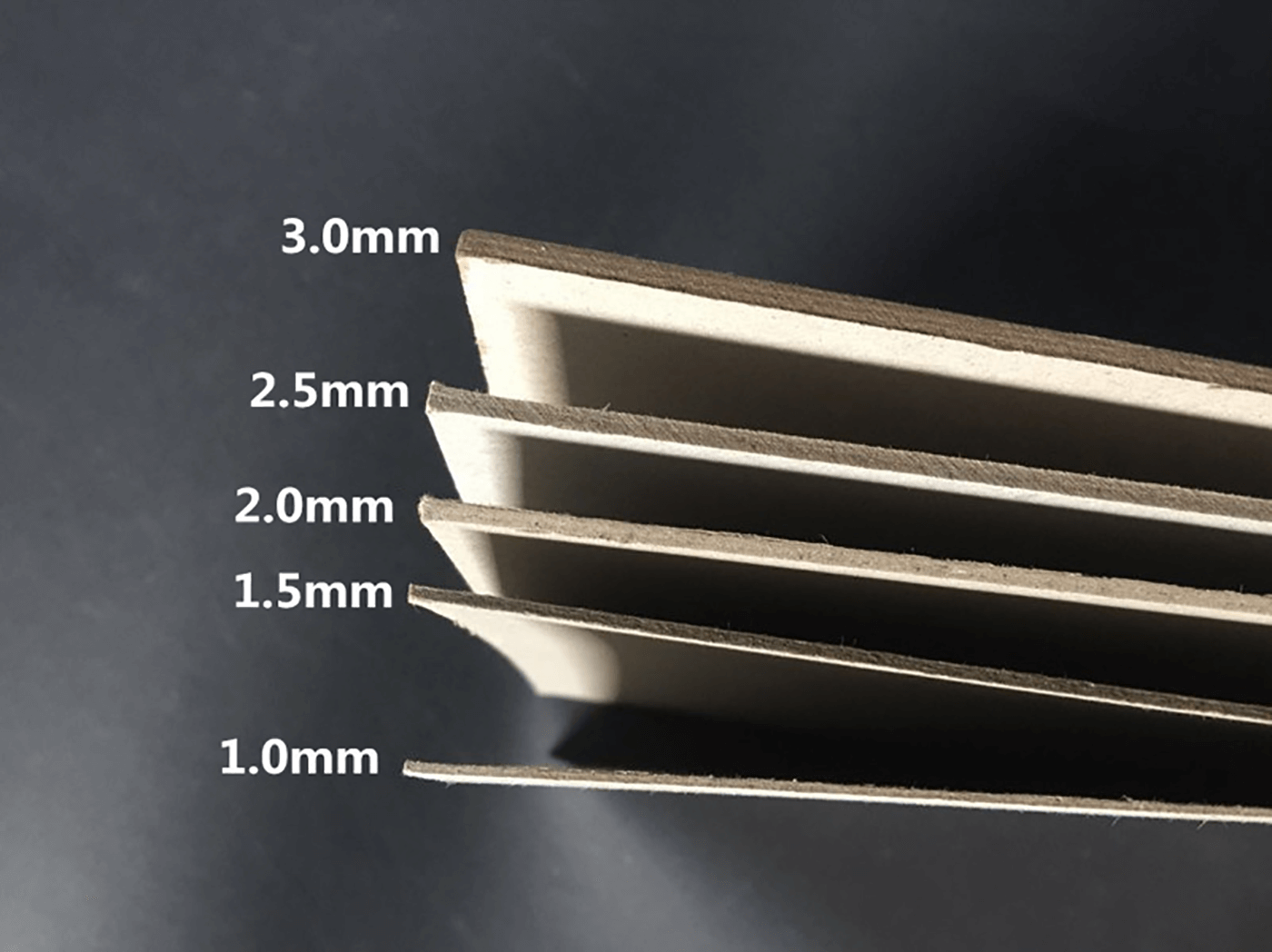

It usually in 1mm, 1.5 mm, 2mm, 2.5 mm gray board. It can be folding flat when shipping.

It can be used for shipping, gifts, logistics packaging.

Basic Info.

|

Product Name |

White Cardboard Gift Box |

Surface Handling |

Glossy lamination, matte lamination, Embossed, Spot UV |

|

Box Style |

OEM Design |

Logo Printing |

Customized Logo |

|

Material thickness |

1 mm, 1.5mm, 2 mm, 2.5 gray board |

Origin |

Ningbo |

|

Materials type |

Single gray board, double gray board, single white board, single black board... |

Sample |

Accept custom samples |

|

Shape |

Rectangle |

Sample Time |

7-10 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

10-15 working days based on quantity |

|

Printing |

Offset Printing, UV Printing |

Transport Package |

Strong 5 ply Corrugated Carton |

|

Type |

Offset Printing, UV printing |

MOQ |

2000PCS |

Detailed Images

We have full automatic mechanical equipment for classic gray board gift box. We have own professional team to check structure, printing and forming. Die-cut designer will adjust box size for different materials. Please attach more details below.

Material Structure and Application

Classic gray board gift box use strong materials in 1mm, 1.5 mm, 2mm, 2.5mm.

There are several kinds of gray board, such as single/double gray board, single white board, single black board.

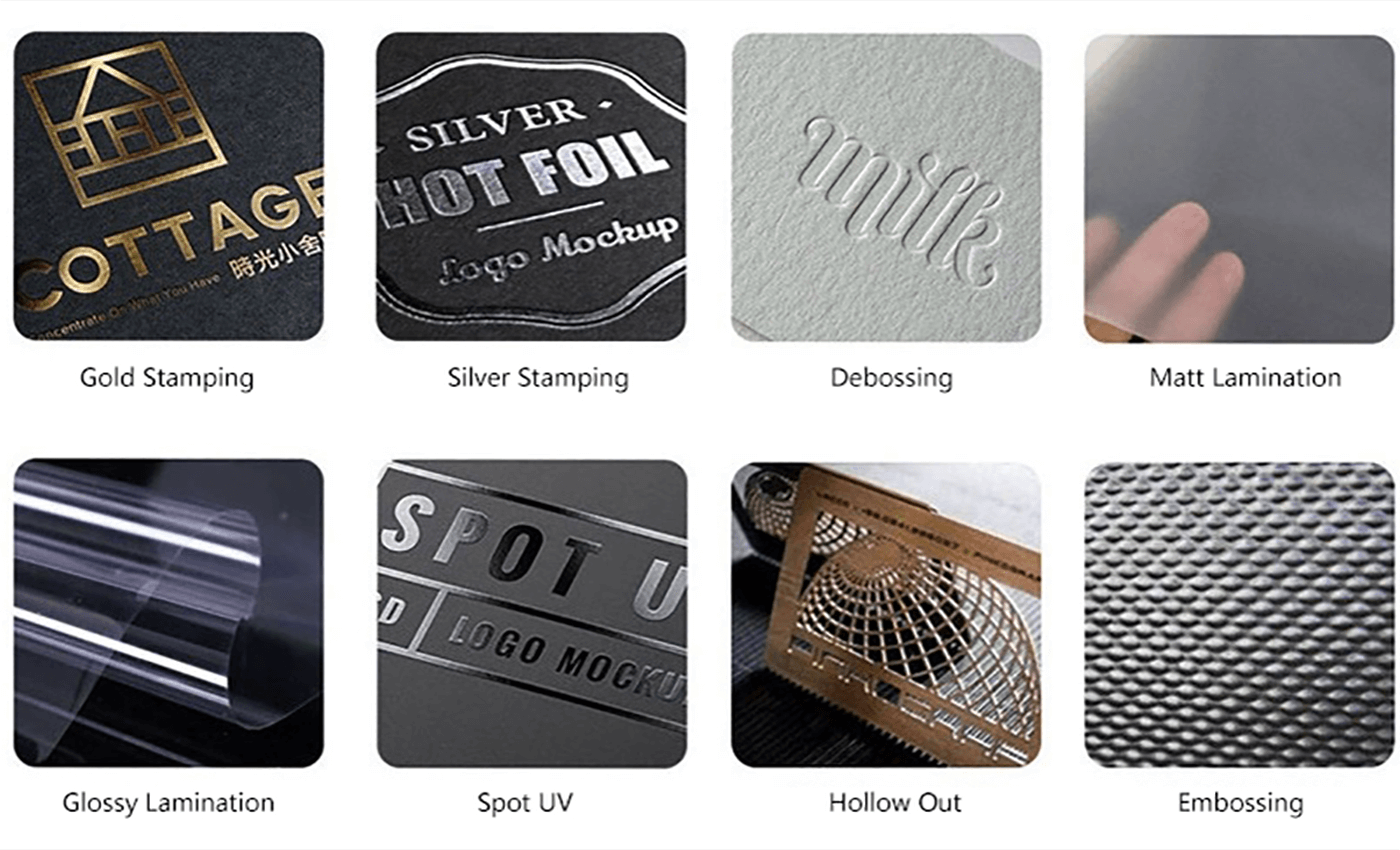

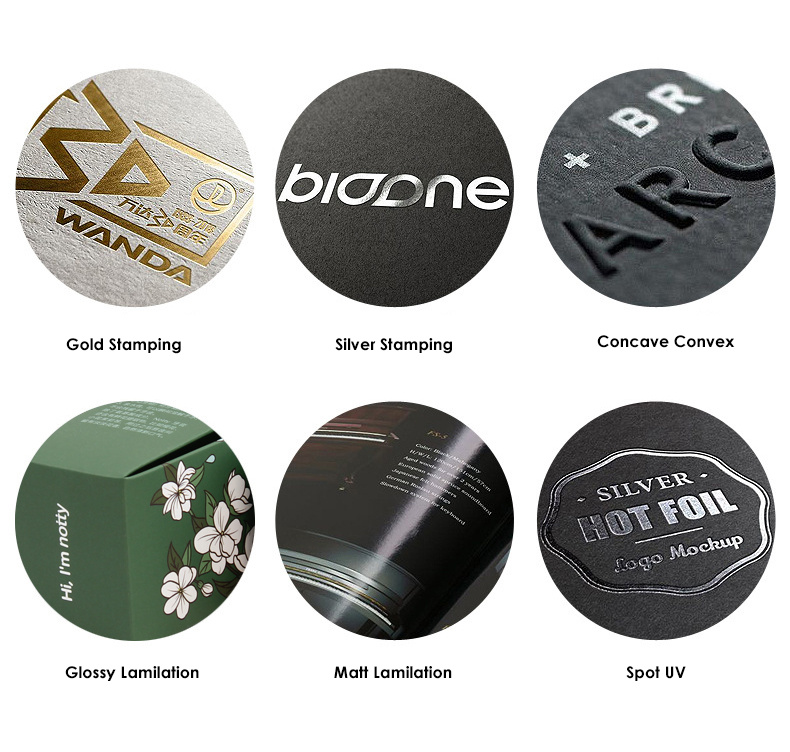

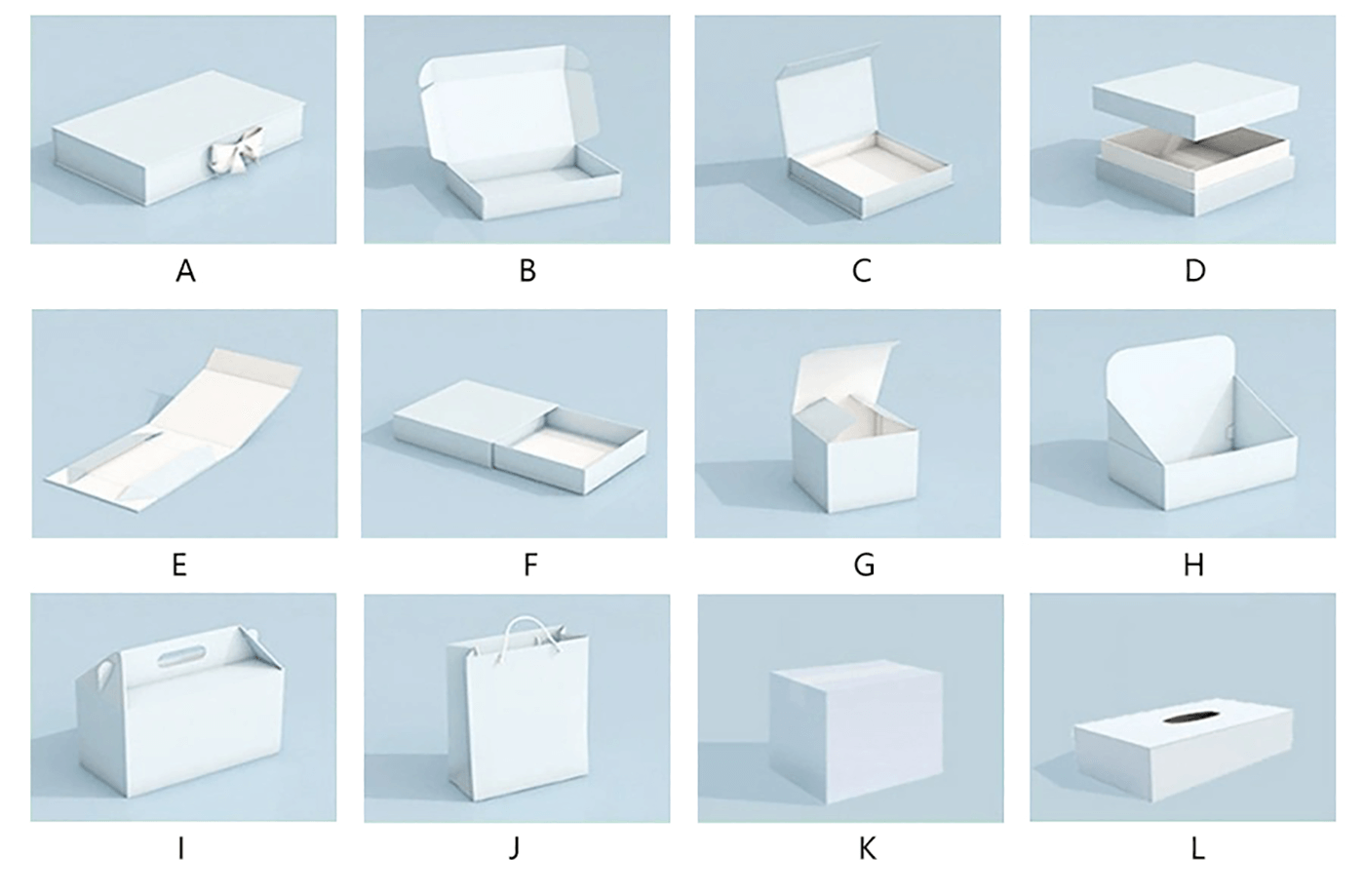

Box Type and Finish Surface

The box type as follow

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment As Follows

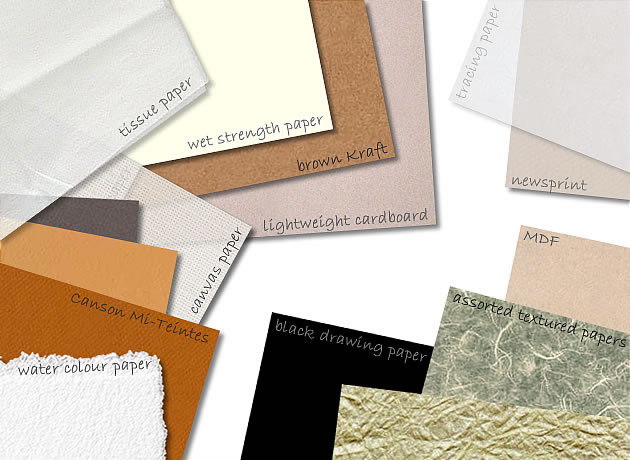

Paper Type

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Black Card Paper

Black cardboard is colored cardboard. According to different colors, it can be divided into red card paper, green card paper, etc. Its biggest drawback is that it can not print color, but it can be used for bronzing and silver stamping. The most commonly used is white card.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for printing advanced picture books, calendars and books, etc.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Ⅰ Material Structure

Paper Gift Box

◆ Gift box is a practical gift packaging which mainly aims at presenting gifts to relatives and friends to express affection. It is an extension of the social needs of a functional packaging way.

Gift box is the embodiment of the soul. we make love gifts or buy love goods to show romantic, mysterious, surprise by paper package. When you slowly open it like open the secret forest in your heart. Gift box expressing to him/her what you want in the mind. This is the meaning of the gift box.

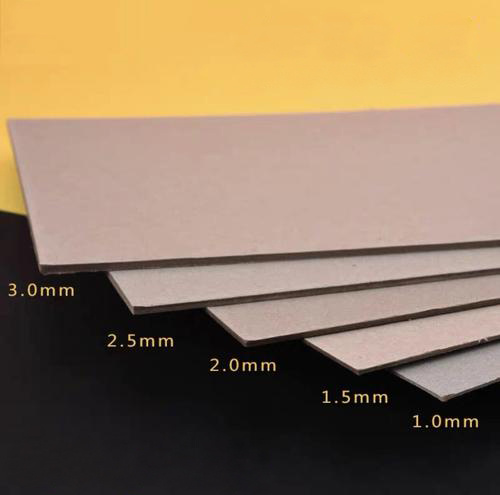

◆Grey board paper

Grey board paper is a kind of paperboard made of recycled waste paper.

It is a kind of environmental protection packaging material.

Products are divided into single gray, double gray, single white, single black.

◆ Specification of Grey board paper

|

Gram |

Thickness |

|

800 g |

1.05+ 0.05mm |

|

1200 g |

1.65+ 0.05mm |

|

1500 g |

2.10+ 0.05mm |

|

1800 g |

2.55+ 0.05mm |

|

2100 g |

3.00+ 0.05mm |

◆Main applications

packaging boxes, advertising boards, folders, photo frame backboards, bags, hardcover books, storage boxes, samples, lining boards, partitions, etc.

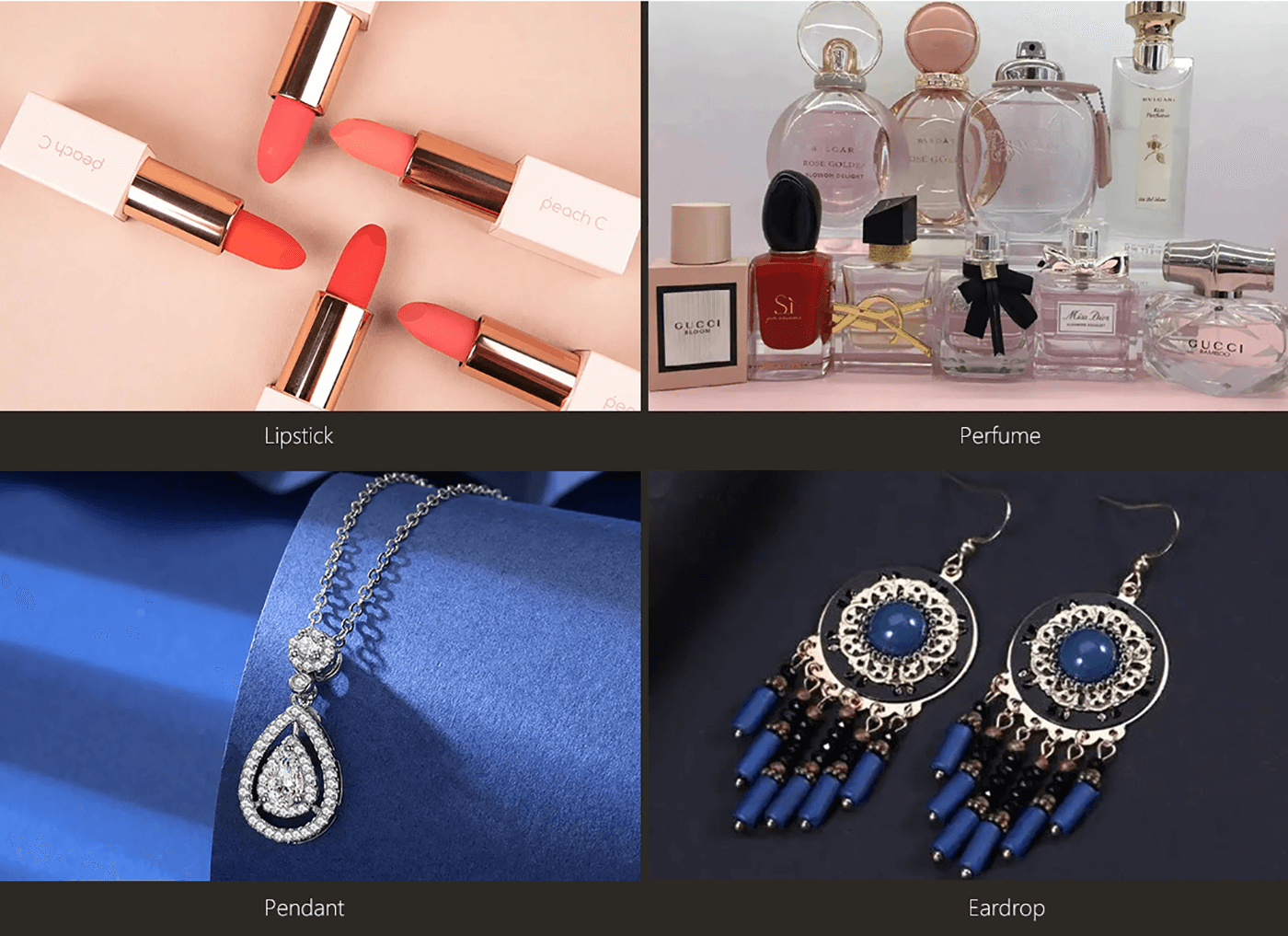

Ⅱ. Application Scenarios

◆Development current situation

With the increasing awareness of environmental protection, coupled with the increasing scarcity of global forest resources ,water and soil resources, the harvesting of wood, paper materials is increasingly restricted in many countries.

At present, the annual global demand for paper products has reached 100 million metric tons, of which the United States accounts for about 31%, Europe including Eastern Europe about 25%, China about 10%, Japan about 9%.

Developed countries such as Europe, the United States and Japan, because of their high domestic manufacturing costs, leading to the relocation of manufacturing. Paper production annual growth rate will be low or even negative growth. On the contrary, emerging developing countries such as China, India, Indonesia, Malaysia, Thailand and Vietnam. Because of their low manufacturing costs.

Ⅰ. Box Type

◆ Classic gift box types

① Drawer box design

Divided into inner box and box set in two parts.

Open and close in the extraction way, with more paper, slightly higher price.

Comparing with world box, it is good at quality packaging, more with opening ceremony sense.It is suitable for the vast majority of categories of products.

② Book box design

The packaging style is like a book, and the box is opened from one side,composed of the outer plate and the inner box. According to the size and function of the customized packaging box, some book boxes need magnets, iron and other materials. It is one of the high-end gift box options.

③World cover box design

Two parts: box cover and bottom box.

The separation of the two, slightly higher cost, but good texture, can also be made of double thickness to increase the robustness. It is suitable for boutique gift boxes, such as clothing, jewelry or food gift boxes, which can improve the product image.

◆ Main type of Gift Boxes

Ⅱ Surface Disposal

◆Classic surface treatment

❶ Gold stamping ❷ Silver Stamping

Gilding process is to use the principle of hot pressing transfer. The aluminum layer of electrolytic aluminum transfer to the substrate surface to form a special metal effect. Main material used in gilding is electrolytic aluminum foil, so gilding is also called electrolytic aluminum hot stamping.

❸ Debossing ❽ Embossing

Concave is the use of concave template (negative template) through the action of pressure. The surface of the printed matter is imprinted into a sense of depression relief pattern. Printed matter is locally depressed, so that it has a three-dimensional sense, causing visual impact.

Features: Can increase the three-dimensional sense of application range.

Suitable for more than 200g paper, mechanism sense obvious high weight special paper.

Note: with bronzing, local UV process effect is better.If the concave template after heating on the special hot melt paper, it will achieve extraordinary artistic effect.

❹ Matt Lamination ❺ Glossy lamination

Laminating is the plastic film coated with adhesive. Paper as substrate printed matter, after the rubber roller and heating roller pressure together, forming a paper-plastic product.

Covered with matte film, is in the name card surface covered with a layer of frosted texture film;

Coating film, is a layer of glossy film on the surface of the business card.

The coated products, due to its surface more than a layer of thin and transparent plastic film, smooth and bright surface, graphic color more bright. At the same time play the role of waterproof, anti-corrosion, wear resistance, dirty resistance and so on.

❻ Spot UV

Spot UV can be implemented after the film, also can be directly glazing on the print. But in order to highlight the effect of local glazing, It is generally after the printing film, and to cover matte film. About 80% of the local UV glazing products.

❼ Hollow Out

Hollow plate printing is a printing term, referring to the engraving of images and texts on wood, cardboard, metal or plastic and other pieces of wood, and hollowed out to make hollow plate. By brushing or spraying method to make ink through the hole attached to the substrate.

◆Common surface treatment effect