Manufacturer Degradable Paper Carton Strong Corrugated Cookware Packaging Box for Display

Description

The printing method is offset printing.

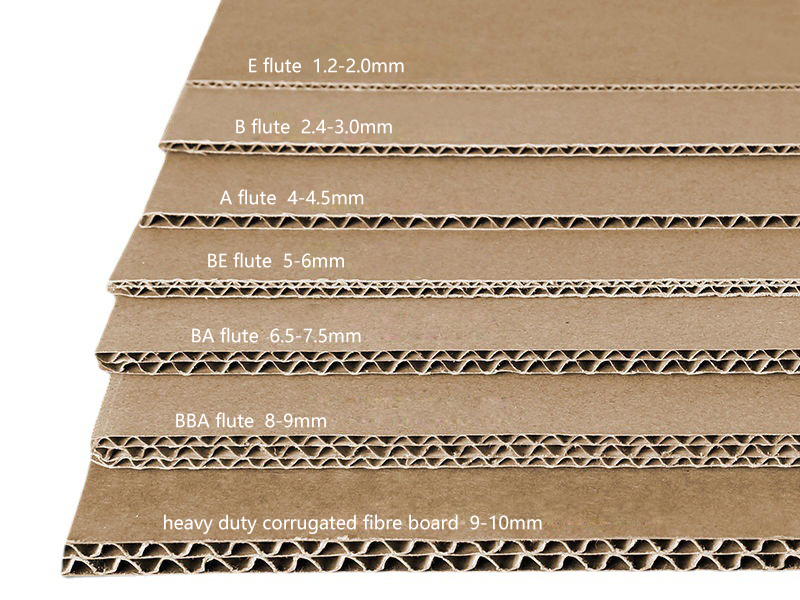

The material is three-layer corrugated cardboard, and the commonly used corrugated types are C flute, B flute and E flute. You can communicate with the salesperson in detail and select the appropriate materials to adapt to the products of different weights and sizes.

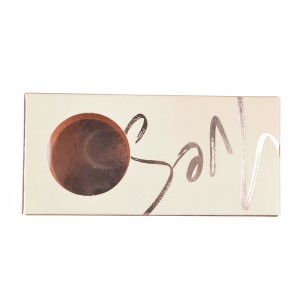

The packaging box with windows can directly display the style and quality of products to attract consumers to buy products.

One corner of material warehouse.

Basic Info.

|

Product Name |

Color Carton Box |

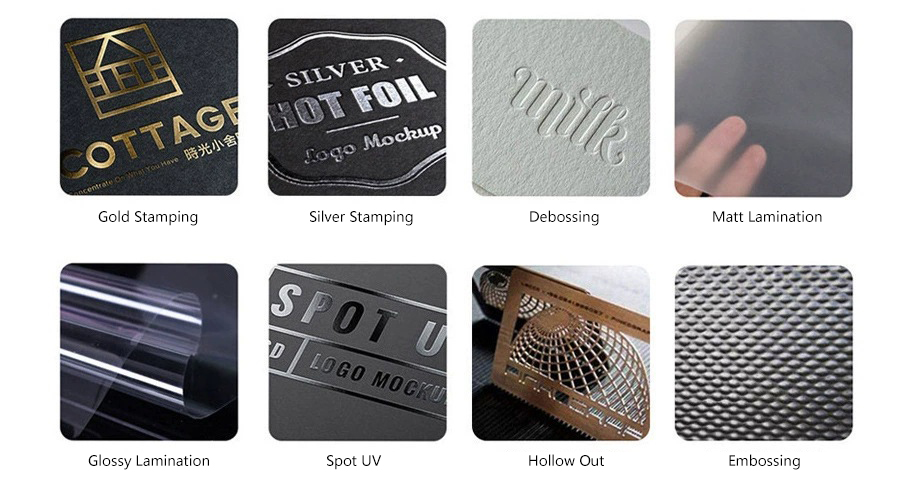

Surface Handling |

Glossy lamination, Matte lamination, Spot UV, Gold Stamping |

|

Box Style |

Hanging Foldable Box |

Logo Printing |

Customized Logo |

|

Material Structure |

White Board + Corrugated Paper + White Board/kraft paper |

Origin |

Ningbo |

|

Materials Weight |

300gsm white grayboard/120/150 white kraft, E flute/B flute/C flute |

Sample |

Accept custom samples |

|

Shape |

Customized |

Sample Time |

5-8 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

8-12 working days based on quantity |

|

Printing |

Offset Printing |

Transport Package |

Strong 5 ply Corrugated Carton |

|

Type |

Single Printing Box |

MOQ |

2000PCS |

Detailed Images

We can judge the quality of a box from the details. We have a professional team to check every production link.

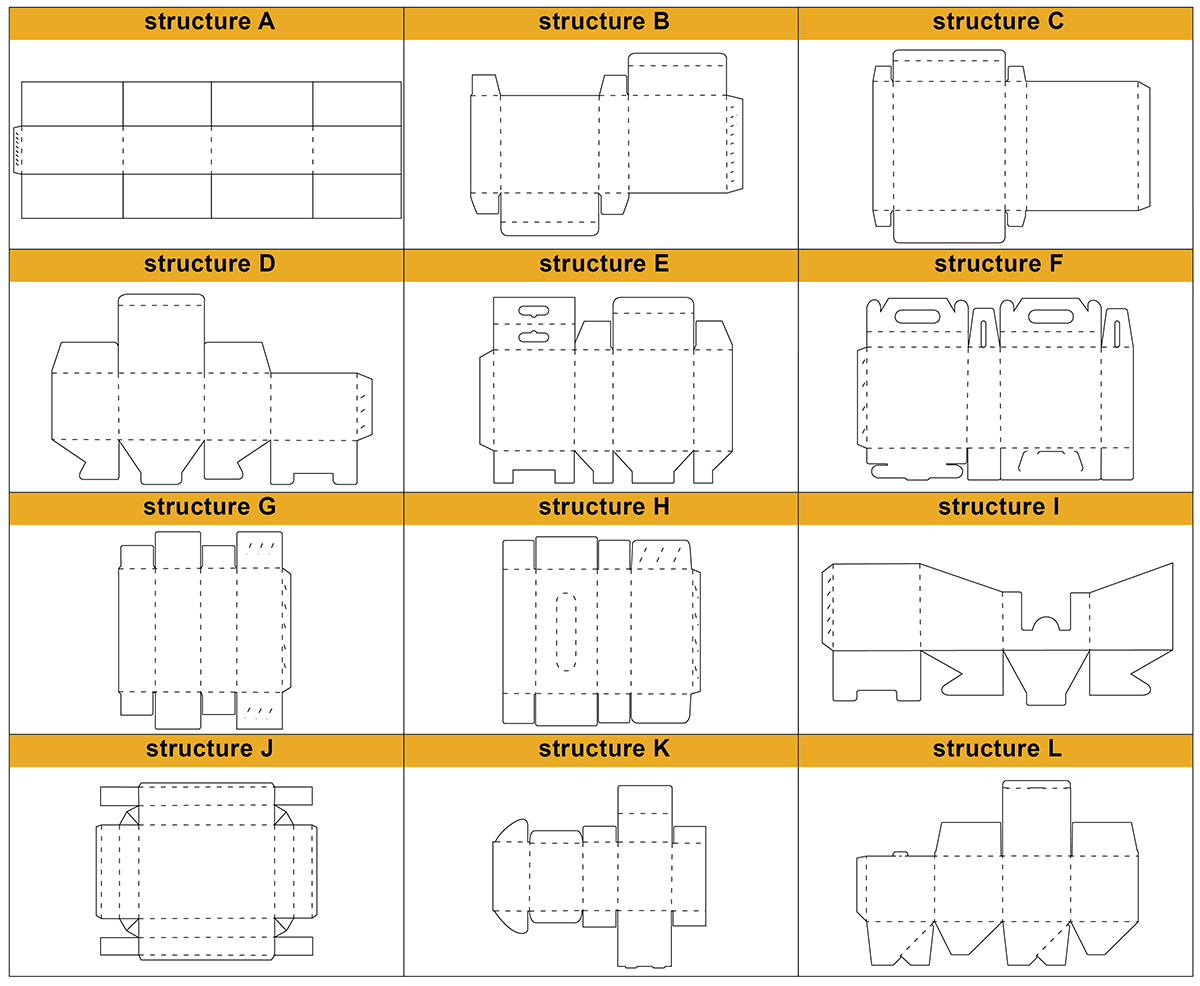

The structural designer will adjust the box structure and knife mold according to the material. Please communicate with the salesperson for details.

Material Structure and Application

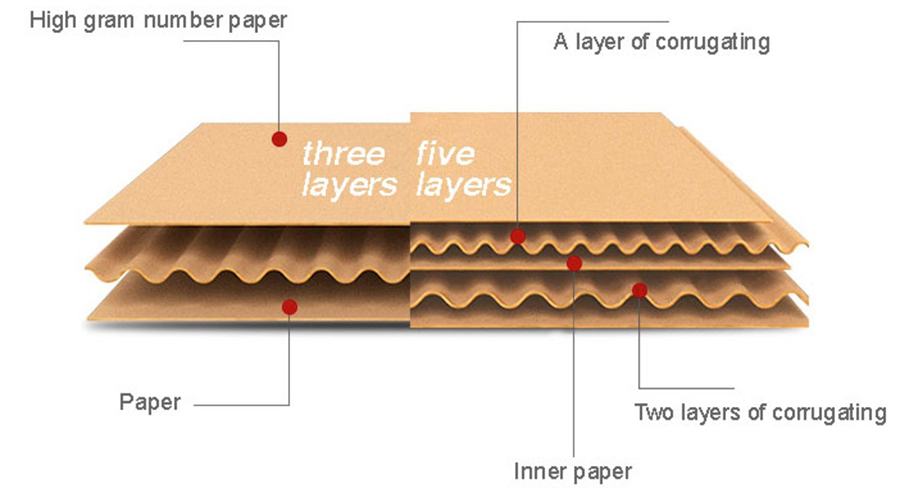

Corrugated paperboard can be divided into 3 layers, 5 layers and 7 layers according to the combined structure, 3 layers and 5 layers are commonly used.

The color printing carton is made by pasting the printed and surface treated outside paper on the corrugated cardboard and die-cutting. Paper with patterns is called outside paper.

The types of face paper and corrugated board can be customized according to needs.

The material structure of the color box and the thickness of the corrugated cardboard are shown below.

The type of outside paper is shown in the figure below.

Packaging Applications

Box Type and Finish Surface

The box type as follow

Surface treatment process