Pink Color 2 Pieces Paper 400gsm White Cardboard Folding Festival Gift Box With Ribbon

Description

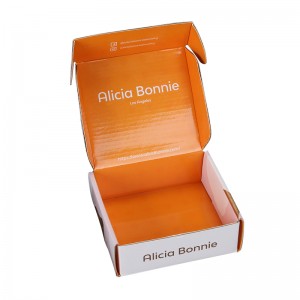

This is a white cardboard paper box, 2 pieces type, the top lid and bottom both are folding style, it’s flat shipping. This kind of box can be used to pack socks, towel, etc. We can print this box according to your design.

Basic Info.

| Product Name | Baby clothes packaging box | Surface Treatment | Glossy/Matte Lamination, spot UV, hot stamping, etc. |

| Box Style | 2 pieces gift box | Logo Printing | Customized Logo |

| Material Structure | Card stock, 350gsm, 400gsm, etc. | Origin | Ningbo city, China |

| Weight | Lightweight box | Sample type | Printing sample, or no print. |

| Shape | Rectangle | Sample Lead Time | 2-5 working days |

| Color | CMYK Color, Pantone Color | Production Lead Time | 12-15 natural days |

| Printing mode | Offset Printing | Transport Package | Standard export carton |

| Type | One-sided Printing Box | MOQ | 2,000PCS |

Detailed Images

These details are used to show the quality, such as materials, printing and surface treatment.

Material Structure and Application

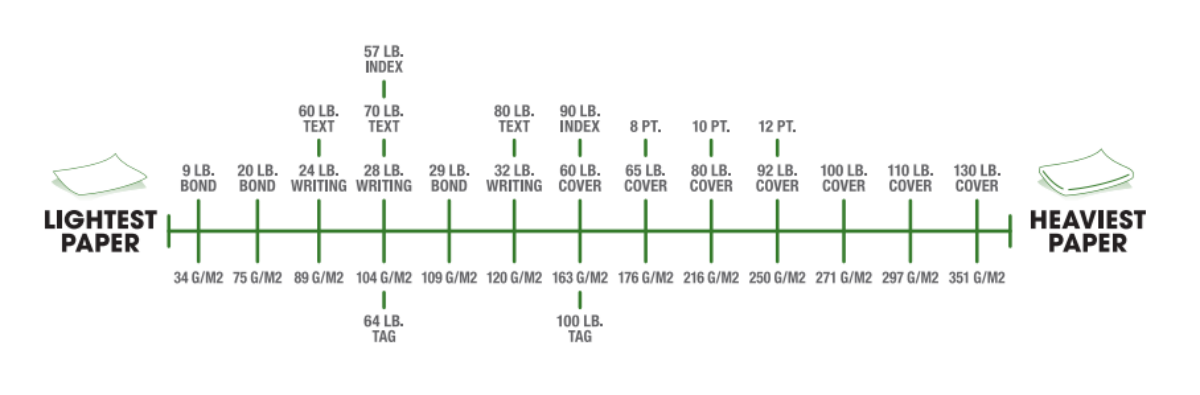

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker (usually over 0.30 mm, 0.012 in, or 12 points) than paper and has certain superior attributes such as foldability and rigidity. According to ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions. Paperboard can be single- or multi-ply.

Paperboard can be easily cut and formed, is lightweight, and because it is strong, is used in packaging. Another end-use is high quality graphic printing, such as book and magazine covers or postcards.

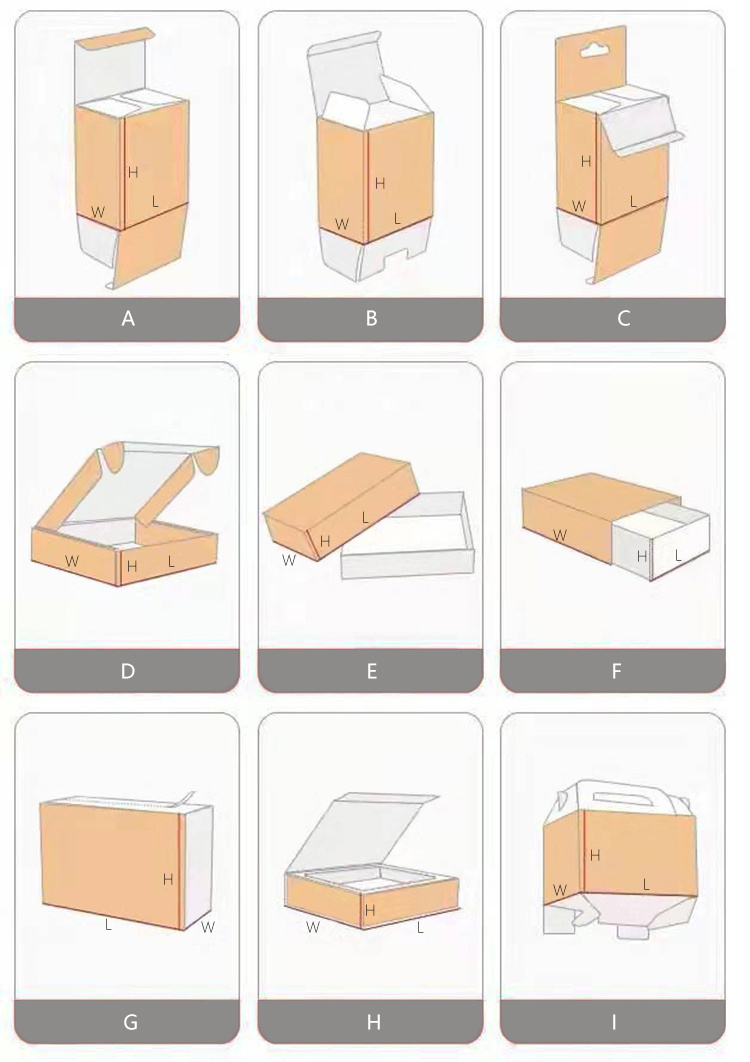

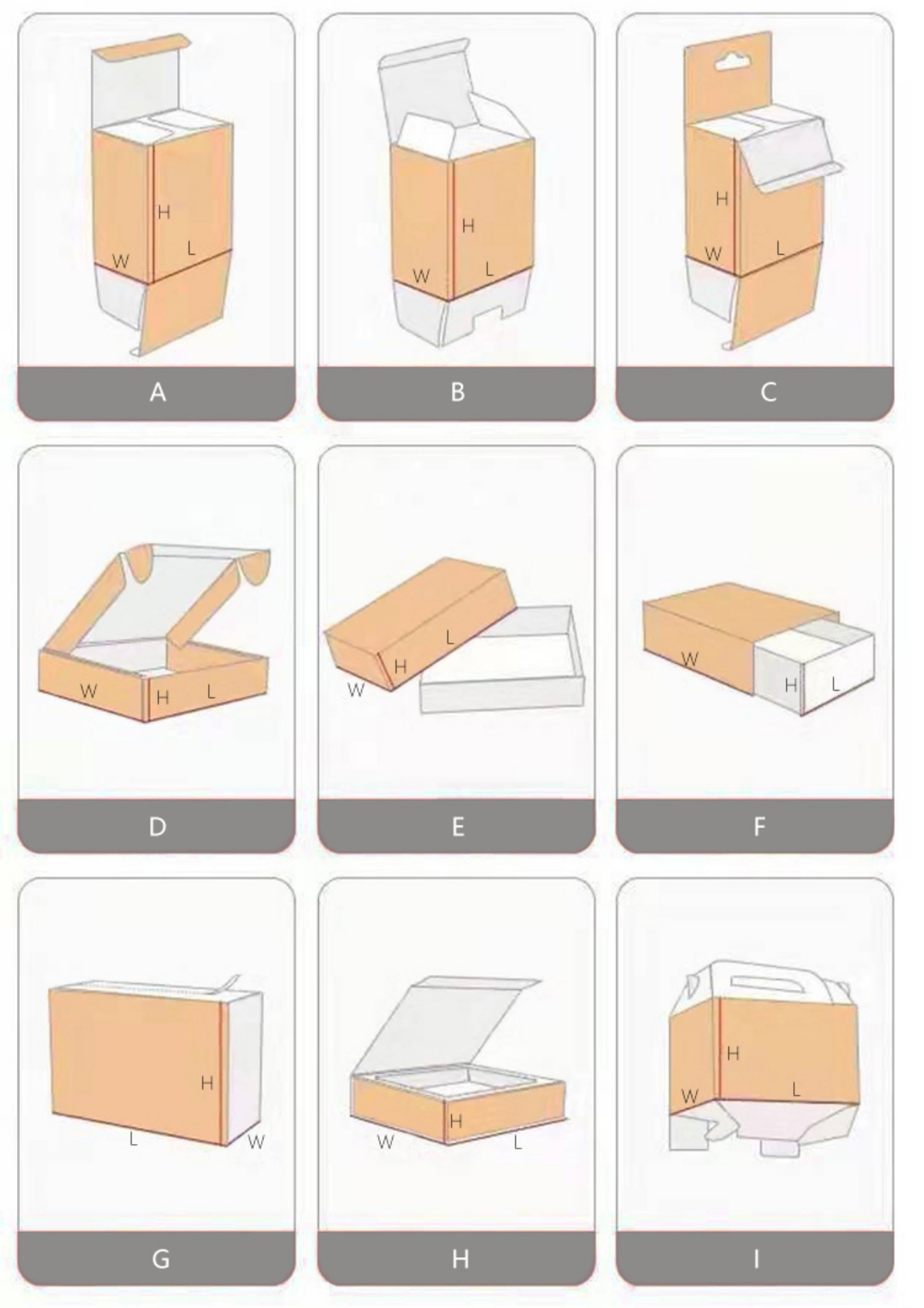

Box Type and Surface Treatment

These box type are used for reference, it can be customized as well.

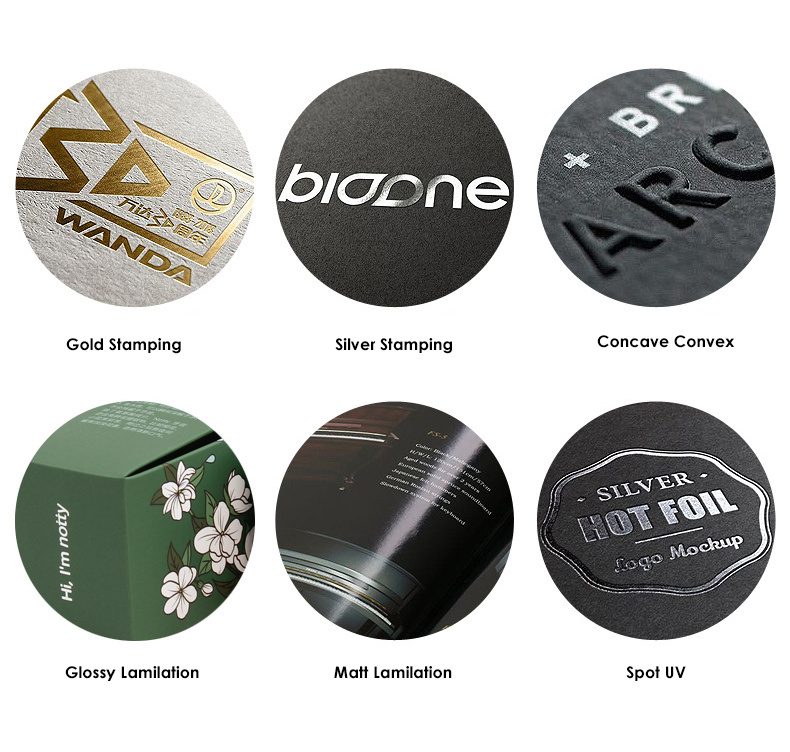

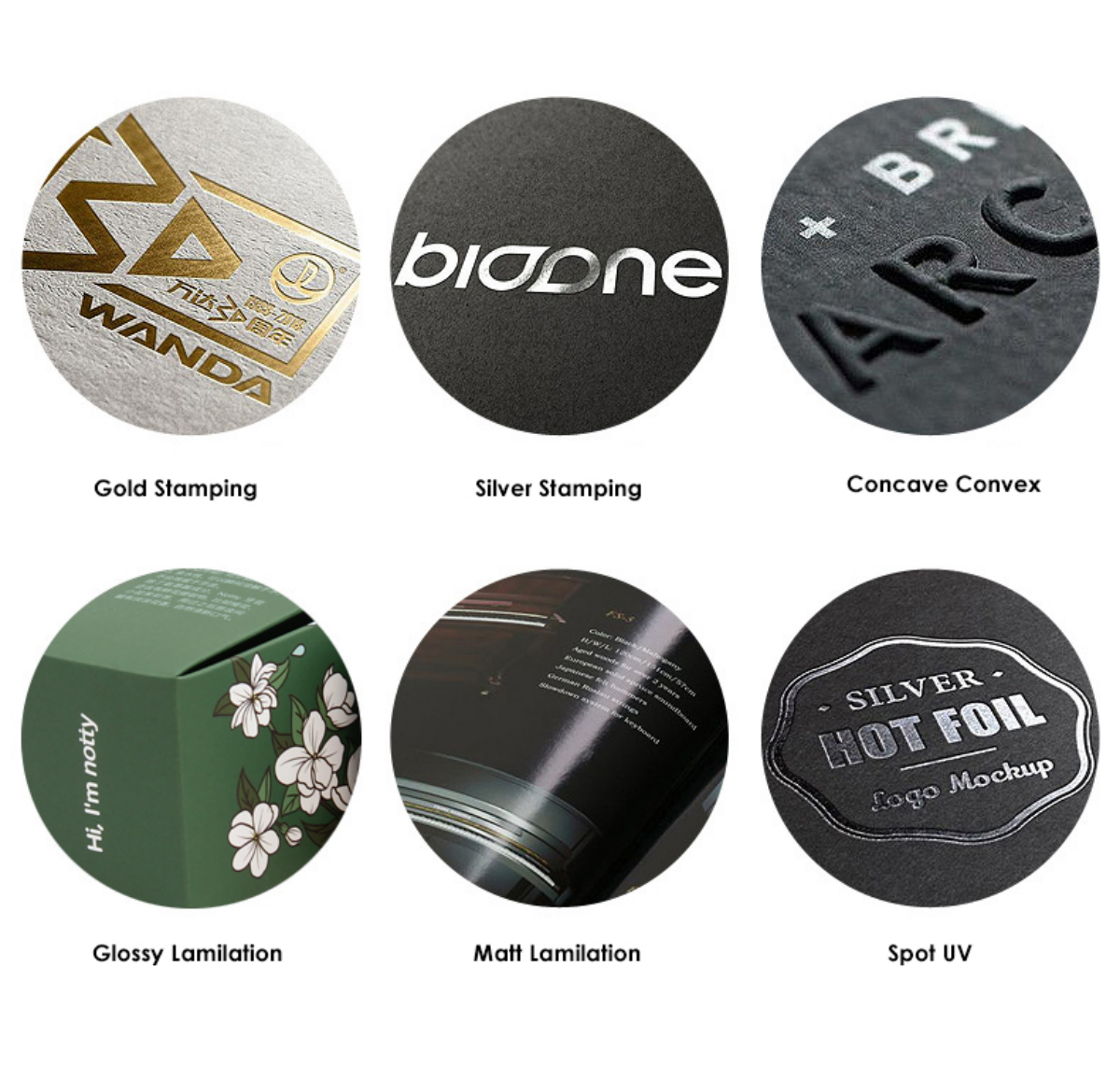

Common Surface Treatment As Follows

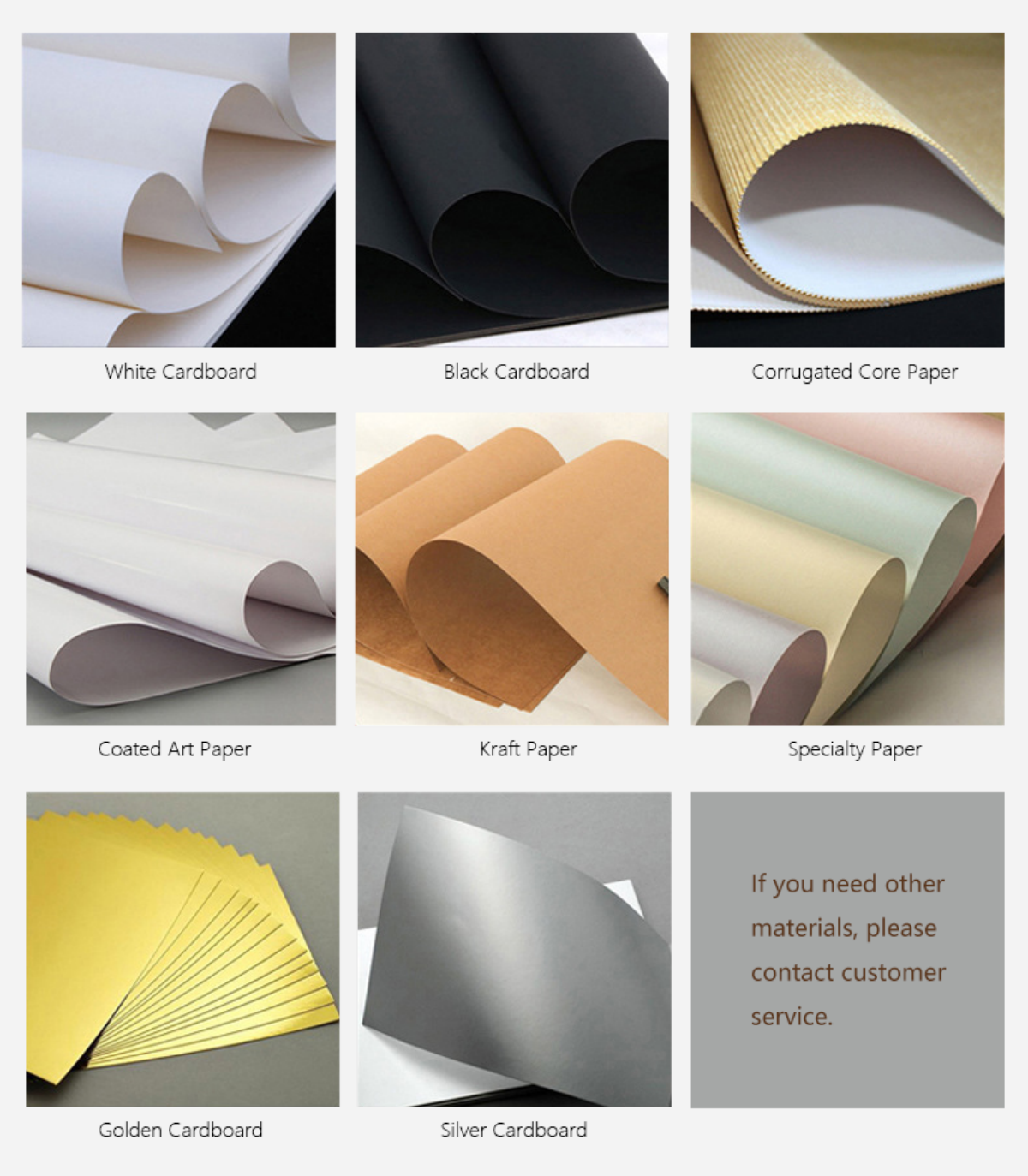

Paper Type

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Material Structure and Application

The popularity of creative paper boxes and paper tubes has risen significantly in recent years, especially in the beauty industry. With consumers increasingly concerned about the environment and the need for sustainable packaging growing, beauty brands and packaging suppliers are adopting eco-friendly designs, using paperboard for folding cartons, paper tubes and more.

One of the main reasons behind this trend is the environmental benefits offered by paperboard packaging. Unlike traditional plastic packaging, cardboard is made from renewable resources and is biodegradable, making it a more sustainable option. This is in line with the values of many beauty brands working to reduce their carbon footprint and adopt more sustainable practices.

Additionally, cardboard packaging is highly customizable and easy to decorate, allowing beauty brands to showcase their creativity and brand identity. This level of customization allows them to create unique and memorable packaging designs that stand out on store shelves and appeal to consumers.

Beauty brands are also recognizing the versatility of paper tubes and creative cartons. These packaging options are suitable for a variety of beauty products including skin creams, lipsticks, fragrances and more. Their compact, lightweight nature makes them ideal for e-commerce businesses as they are easy to ship and transport, reducing the environmental impact of logistics.

Box Type and Finish Surface

These box type are used for reference, it can be customized as well.

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment As Follows