pink 400 gsm cardboard paper mailer gift box with sleeve

Description

This is a small drawer box, it’s packaging for soap.

The cut out slot of inner box can be made as per shape of soap.

The box structure/type can be customized as per your need as well, dimensions can be made as per your products. From this box sample, you can find spot UV on outside of the box, the part which is shiny.

Basic Info.

| Product Name | Soap packaging | Surface Treatment | Matte Lamination, spot UV, etc. |

| Box Style | Slid drawer box | Logo Printing | Customized Logo |

| Material Structure | Card stock, 350gsm, 400gsm, etc. | Origin | Ningbo city, China |

| Weight | Lightweight box | Sample type | Printing sample, or no print. |

| Shape | Rectangle | Sample Lead Time | 2-5 working days |

| Color | CMYK Color, Pantone Color | Production Lead Time | 12-15 natural days |

| Printing mode | Offset Printing | Transport Package | Standard export carton |

| Type | One-sided Printing Box | MOQ | 2,000PCS |

Detailed Images

These details are used to show the quality, such as materials, printing and surface treatment.

Material Structure and Application

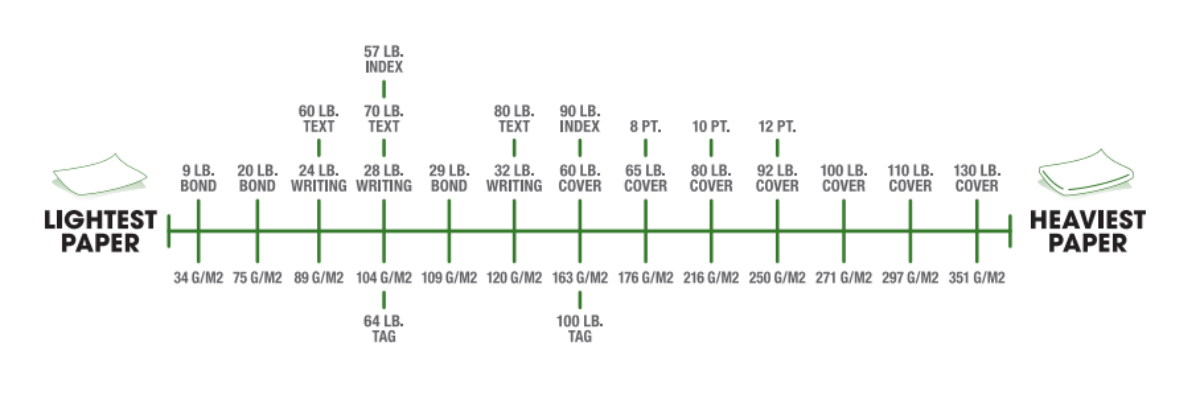

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker (usually over 0.30 mm, 0.012 in, or 12 points) than paper and has certain superior attributes such as foldability and rigidity. According to ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions. Paperboard can be single- or multi-ply.

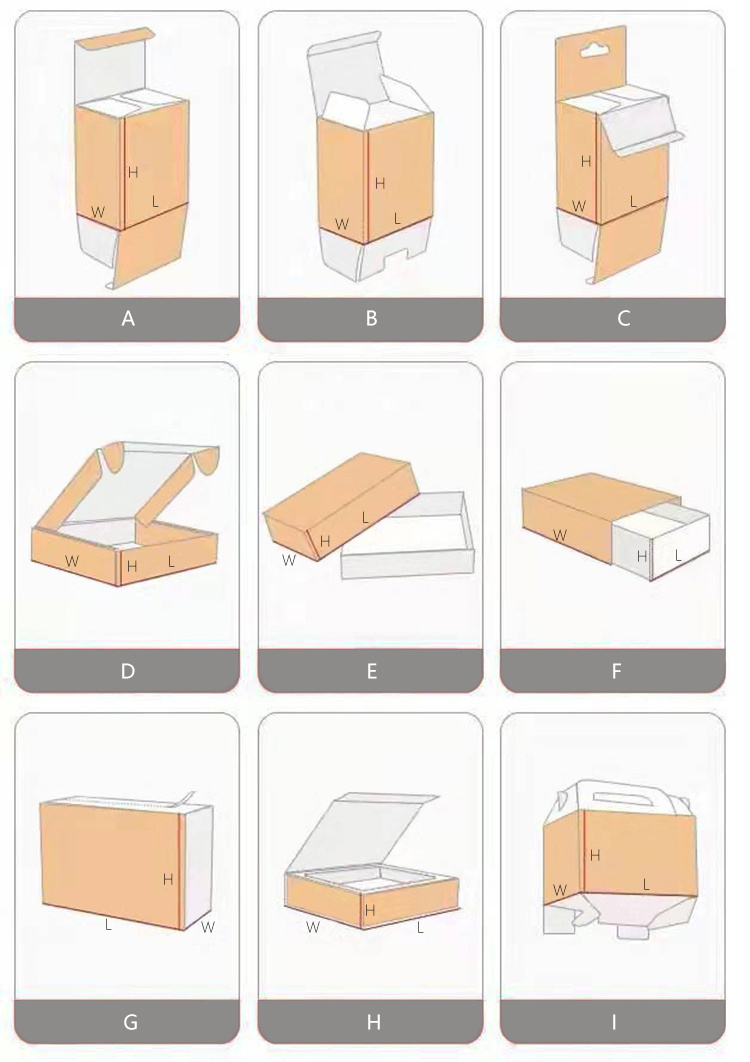

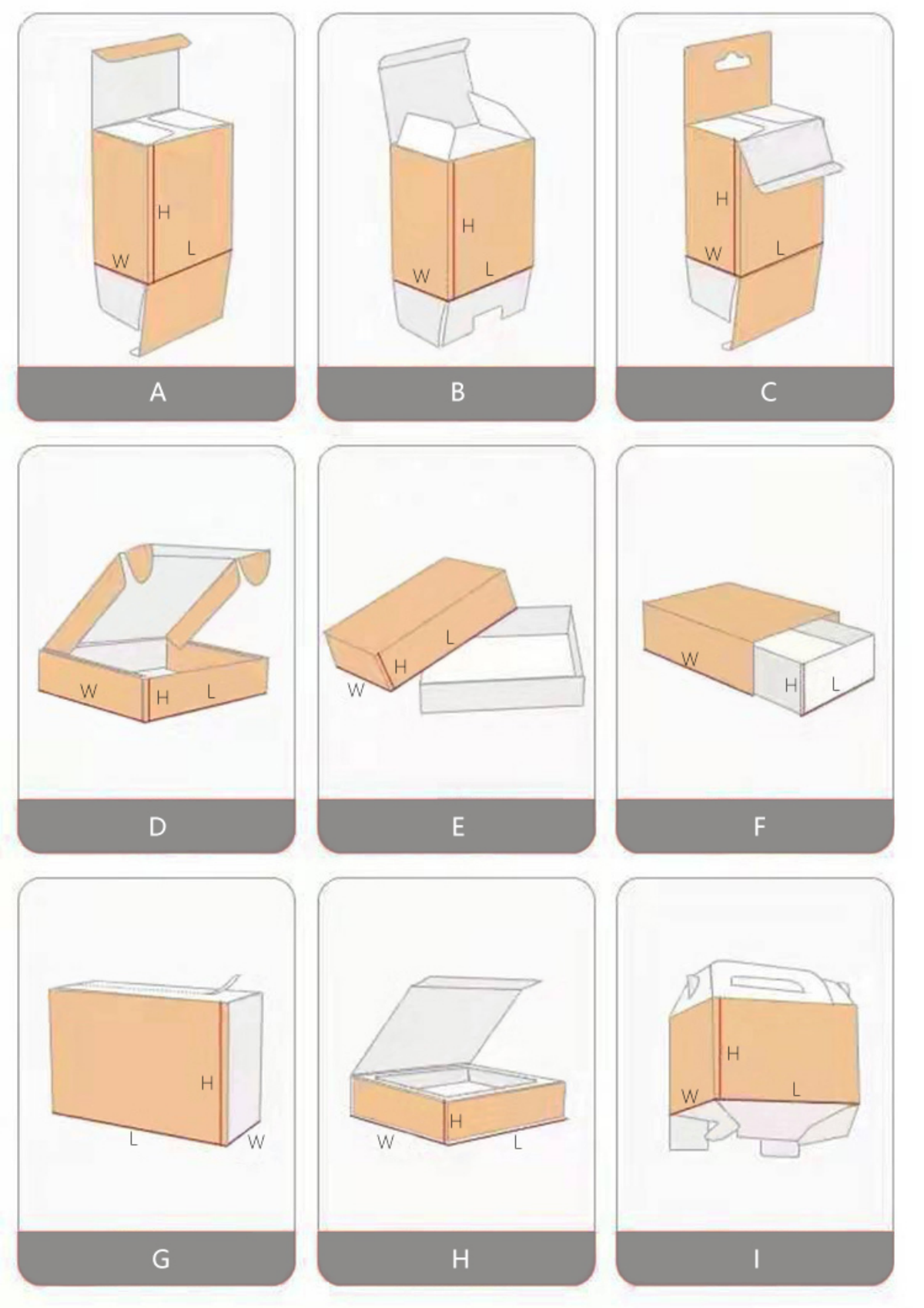

Box Type and Surface Treatment

These box type are used for reference, it can be customized as well.

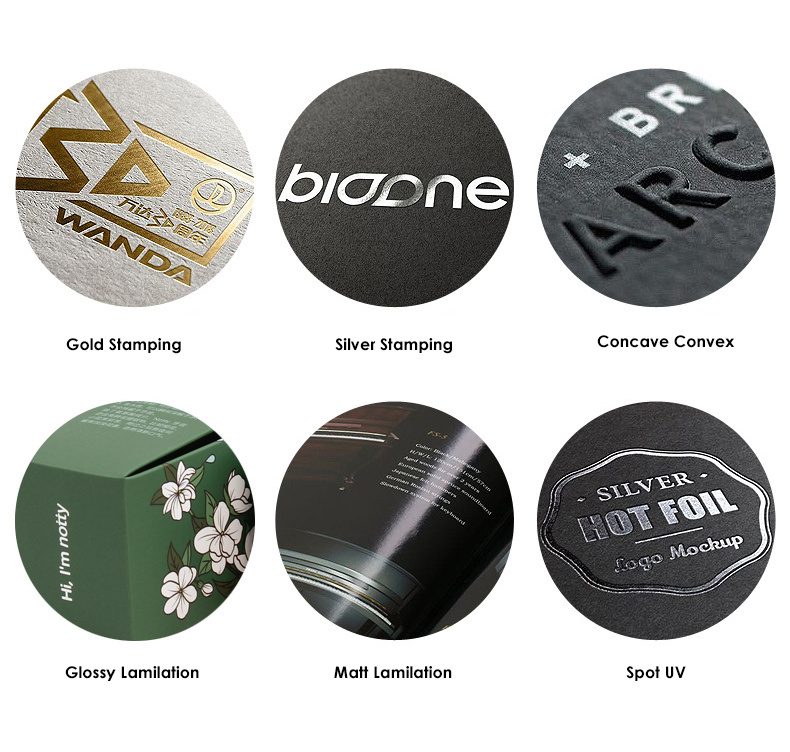

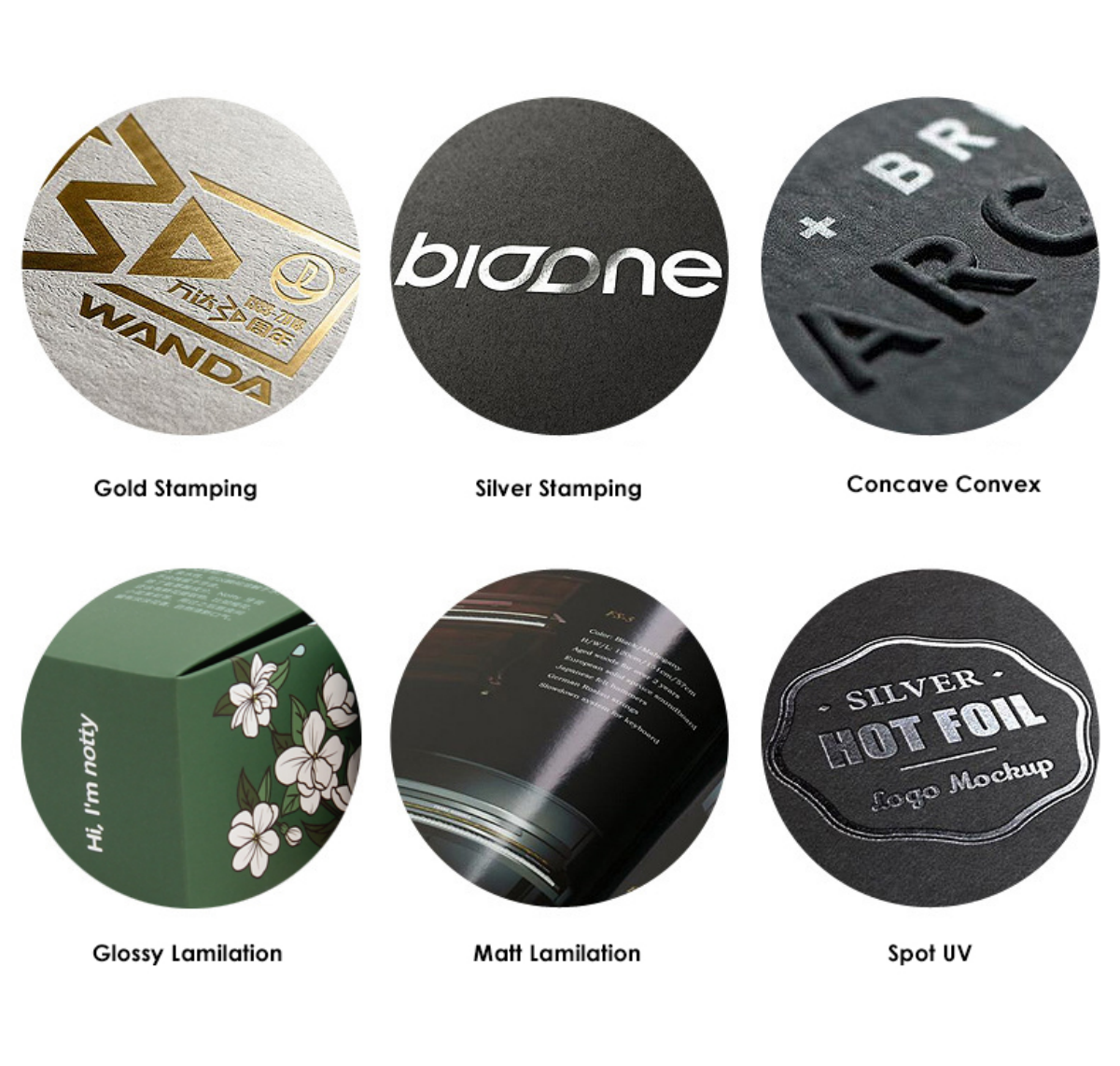

Common Surface Treatment As Follows

Paper Type

| C1S -White Cardboard PT/G SHEET | ||

| PT | Standard gram | Using gram |

| 7 PT | 161 g | |

| 8 PT | 174 g | 190 g |

| 10 PT | 199 g | 210g |

| 11 PT | 225 g | 230 g |

| 12 PT | 236g | 250g |

| 14 PT | 265 g | 300 g |

| 16 PT | 296 g | 300 g |

| 18 PT | 324g | 350g |

| 20 PT | 345 g | 350 g |

| 22 PT | 379 g | 400g |

| 24 PT | 407 g | 400 g |

| 26 PT | 435g | 450 g |

Ivory Board

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Material Structure and Application

In the ever-evolving world of packaging, there is an ever-increasing demand for sustainable and environmentally friendly solutions. With the 2024 paper product packaging export orders approaching, it is time to take a deeper look at the potential impact and opportunities this brings to the industry.

One of the key factors driving demand for paper product packaging is the shift in consumer preferences towards sustainable and biodegradable materials. This provides an opportunity for companies to align with these values and cater to an environmentally conscious consumer base. By taking advantage of the 2024 export orders, companies can expand their reach and tap into new markets that prioritize sustainable packaging solutions.

In addition, export orders also highlight the potential for innovation and technological advancement in the paper packaging industry. As the demand for environmentally friendly packaging solutions continues to grow, continuous research and development is required to improve the quality and functionality of paper packaging. This provides manufacturers with the opportunity to invest in cutting-edge technologies and processes that can further enhance the appeal and performance of paper product packaging.

Box Type and Finish Surface

These box type are used for reference, it can be customized as well.

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment As Follows