Premium Drawer Colorful White Card Paper Packaging Box for Tea Bag

Description

This box consists of two separate parts. The inner box and outer box without cover are sleeved together.

We provide you with free structural drawings so that you can design the printed content.

We will match the appropriate materials for you according to the size, weight and use of the product.

Please communicate with the salesperson for details.

Basic Info.

| Product Name | Envelope Box | Surface Handling | Glossy Lamination/Matte lamination, Hot Stamping, Spot UV |

| Box Style | Self-forming Bottom | Logo Printing | Customized Logo |

| Material Structure | 250 /300/350/400gram ivory board | Origin | Ningbo |

| Single box Weight | 400gram ivory board | Sample | Accept custom samples |

| Shape | Rectangle | Sample Time | 5-7 Working Days |

| Color | CMYK Color, Pantone Color | Production Lead Time | 10-15 days based on quantity |

| Printing | Offset printing | Transport Package | Strong 5 ply Corrugated Carton |

| Type | Single /Two-sided Printing Box | MOQ | 2000PCS |

Detailed Images

We have a professional quality management team, and each process will undergo strict quality inspection. The structural designer designs appropriate structural drawings according to the characteristics of materials and packaging requirements.

Please communicate with the salesperson for details.

The master workers are checking the printing quality

Material Structure and Application

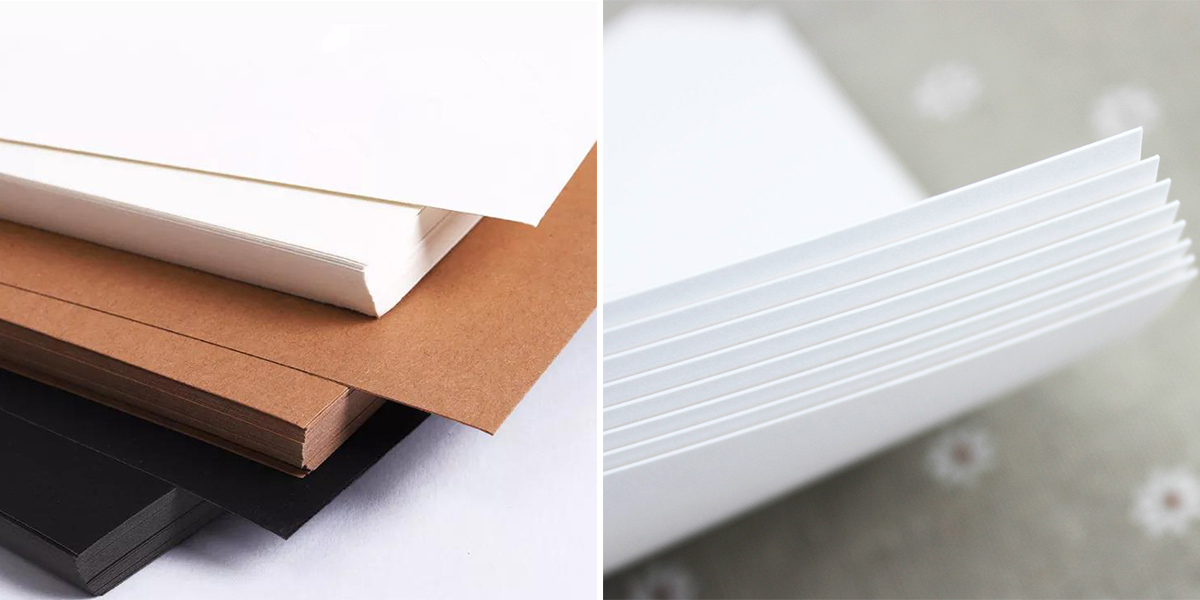

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Black Card Paper

Black cardboard is colored cardboard. According to different colors, it can be divided into red card paper, green card paper, etc. Its biggest drawback is that it can not print color, but it can be used for bronzing and silver stamping. The most commonly used is white card.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for printing advanced picture books, calendars and books, etc.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

white card paper, kraft card paper, black card paper

coated art paper

Application

Box Type and Finish Surface

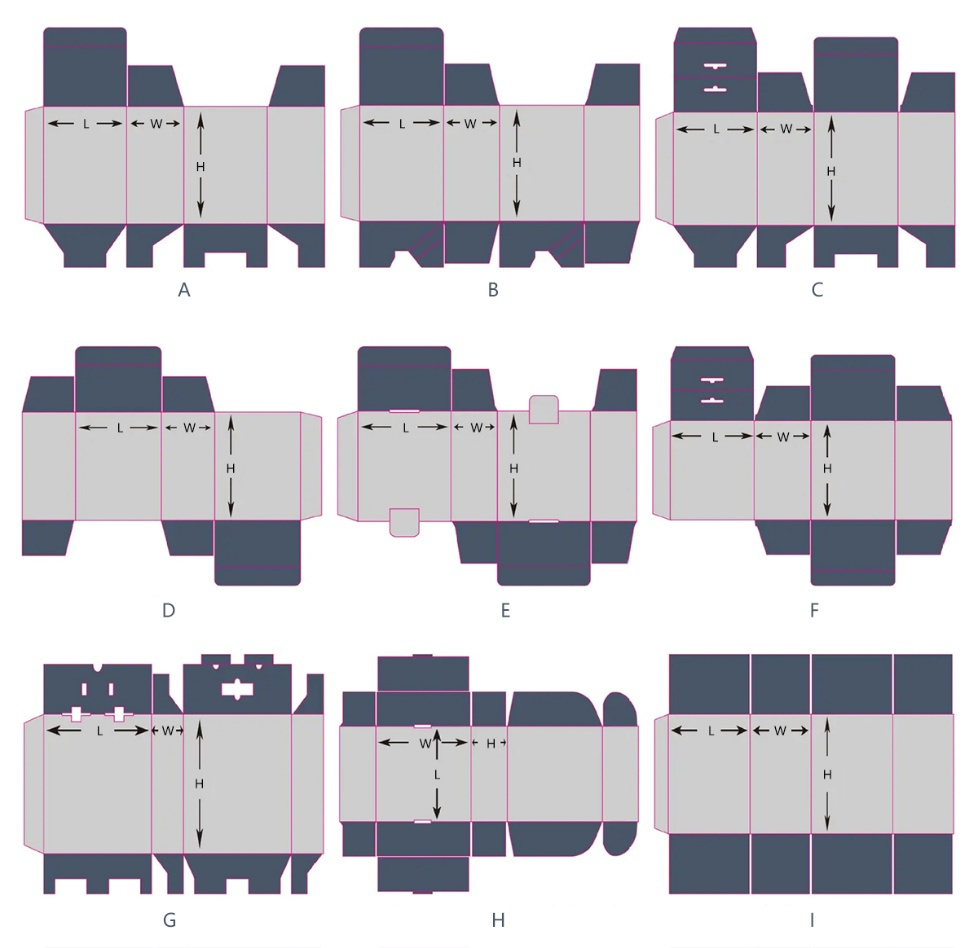

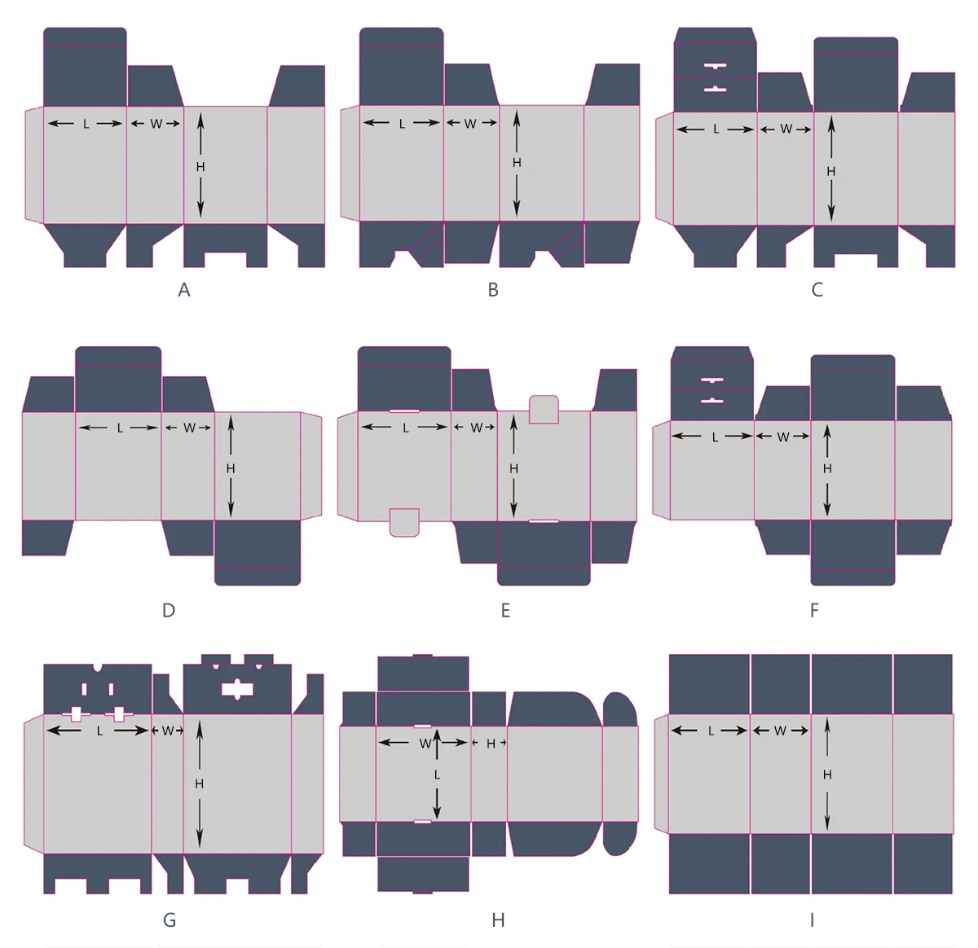

The box type as follow

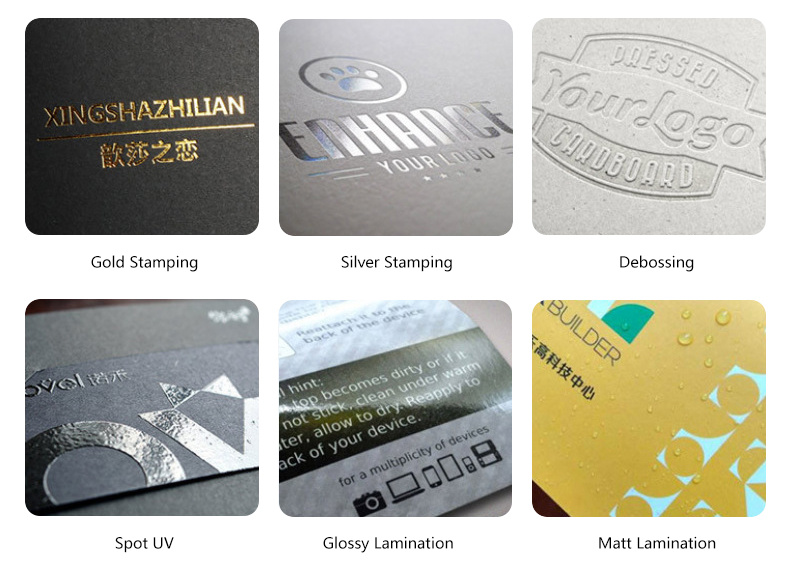

Finish Surface

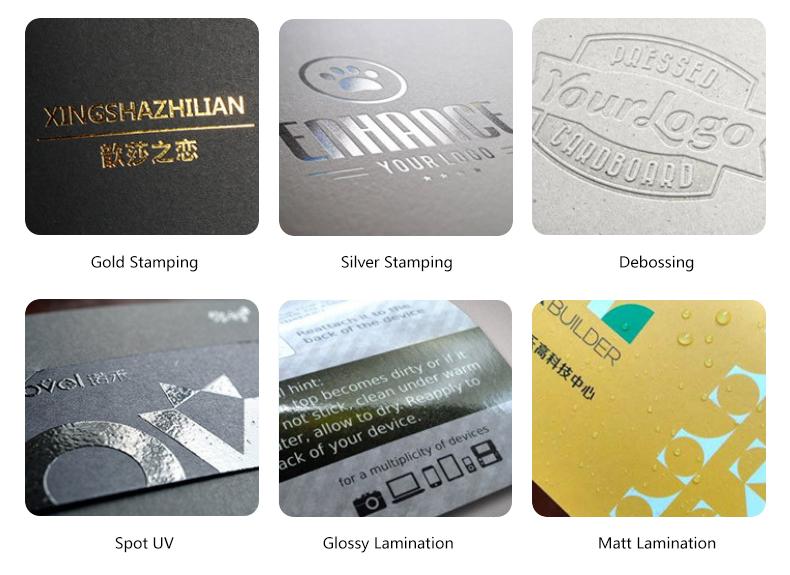

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment as Follows

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Black Card Paper

Black cardboard is colored cardboard. According to different colors, it can be divided into red card paper, green card paper, etc. Its biggest drawback is that it can not print color, but it can be used for bronzing and silver stamping. The most commonly used is white card.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for printing advanced picture books, calendars and books, etc.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

white card paper, kraft card paper, black card paper

coated art paper

Application

The box type as follow

Finish Surface

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment as Follows