oem logo printed small paper gift package gift boxes with PVC window

Description

Carton is a three-dimensional shape, it is composed of a number of planes moving, stacking, folding, surrounded by a multi-faceted shape.

The surface in three-dimensional construction plays the role of dividing space in space. With different parts is cut, rotated and folded, and the surface obtained has different emotions.

The composition of the carton display surface should pay attention to the connection between the display surface, side, top and bottom, and the setting of the packaging information elements.

Basic Info.

| Product Name | Baby products packaging | Surface Treatment | Glossy/Matte Lamination or Varnish, hot stamping, etc. |

| Box Style | product box | Logo Printing | Customized Logo |

| Material Structure | Card stock, 350gsm, 400gsm, etc. | Origin | Ningbo city, China |

| Weight | Lightweight box | Sample type | Printing sample, or no print. |

| Shape | Rectangle | Sample Lead Time | 2-5 working days |

| Color | CMYK Color, Pantone Color | Production Lead Time | 12-15 natural days |

| Printing mode | Offset Printing | Transport Package | Standard export carton |

| Type | One-sided Printing Box | MOQ | 2,000PCS |

Detailed Images

These details are used to show the quality, such as materials, printing and surface treatment.

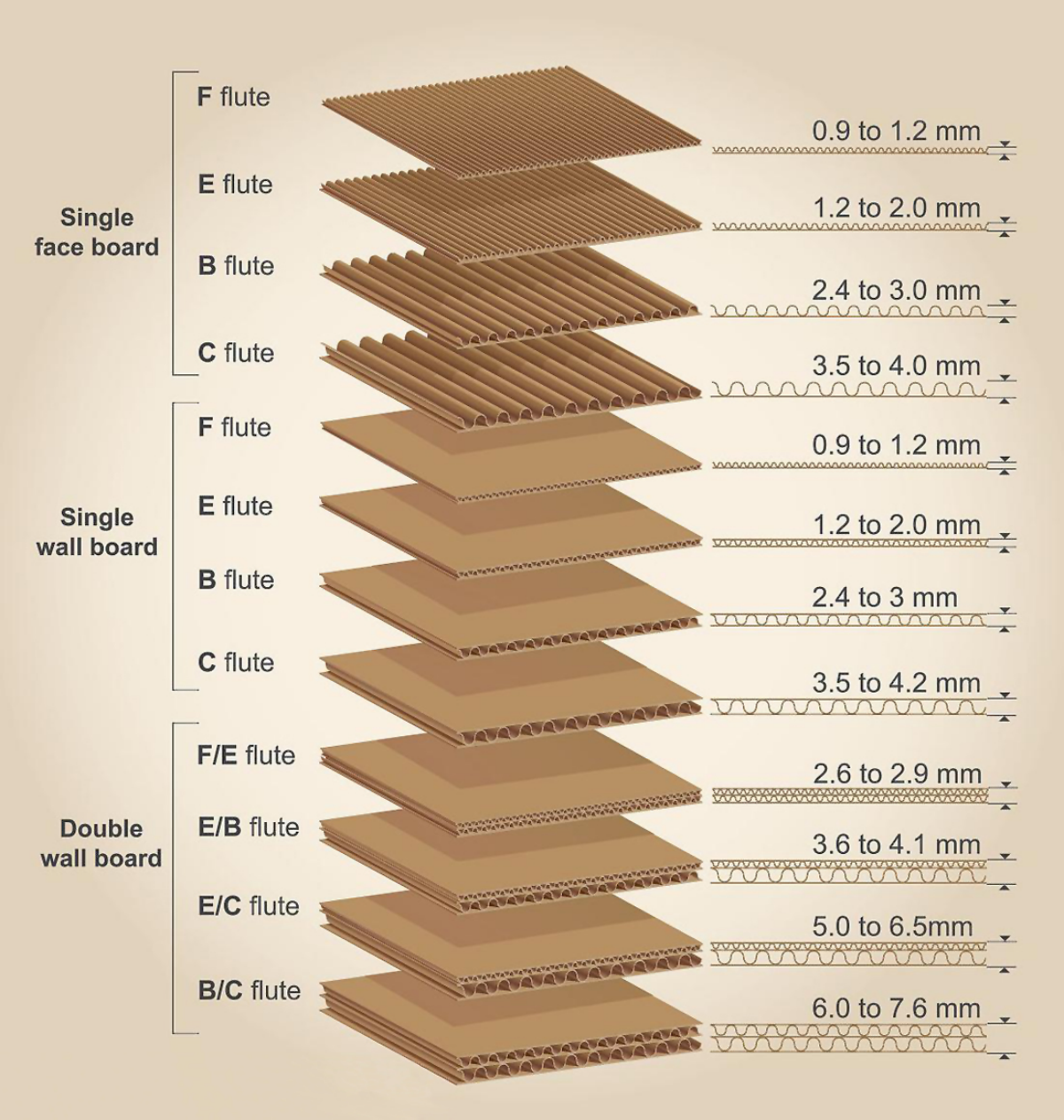

Material Structure and Application

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker (usually over 0.30 mm, 0.012 in, or 12 points) than paper and has certain superior attributes such as foldability and rigidity. According to ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions. Paperboard can be single- or multi-ply.

Paperboard can be easily cut and formed, is lightweight, and because it is strong, is used in packaging. Another end-use is high quality graphic printing, such as book and magazine covers or postcards.

Sometimes it is referred to as cardboard, which is a generic, lay term used to refer to any heavy paper pulp–based board, however this usage is deprecated in the paper, printing and packaging industries as it does not adequately describe each product type.

Terminology and classifications of paperboard are not always uniform. Differences occur depending on specific industry, locale, and personal choice. In general, the following are often used:

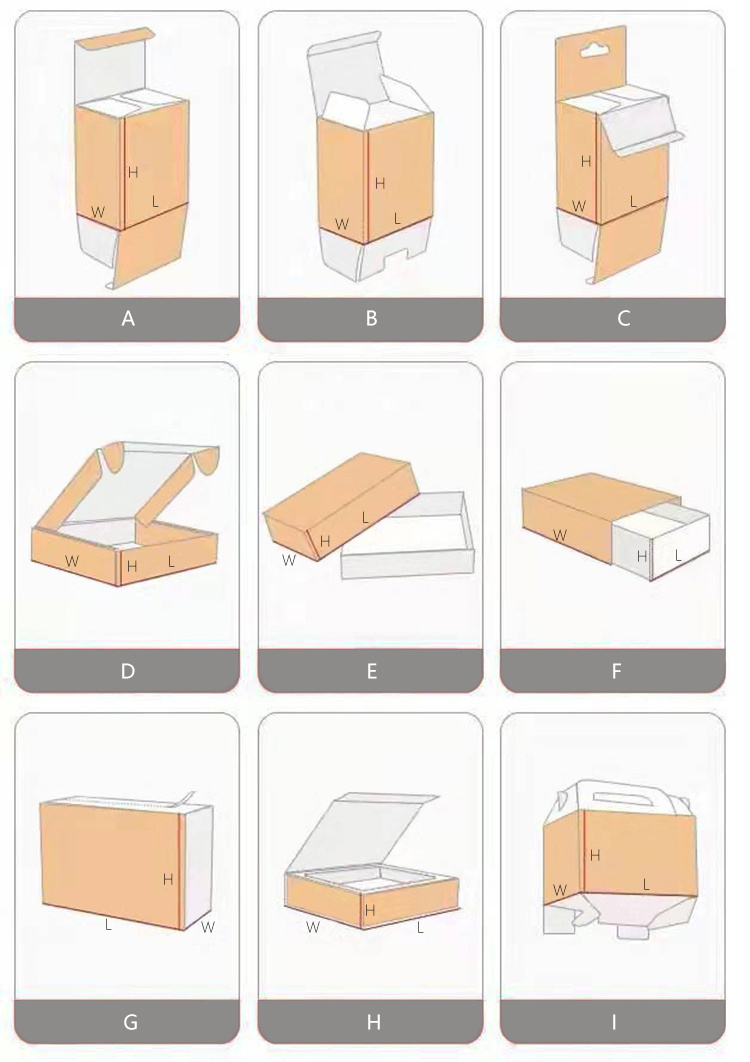

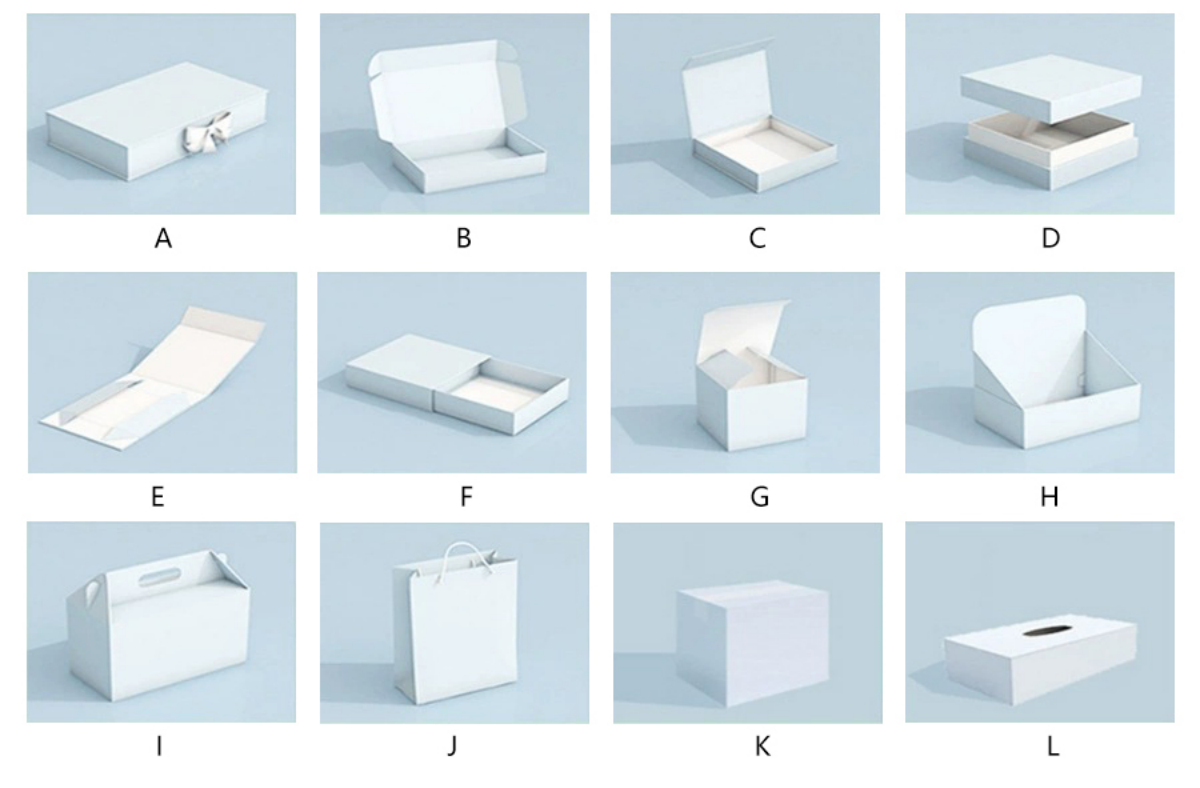

Box Type and Surface Treatment

These box type are used for reference, it can be customized as well.

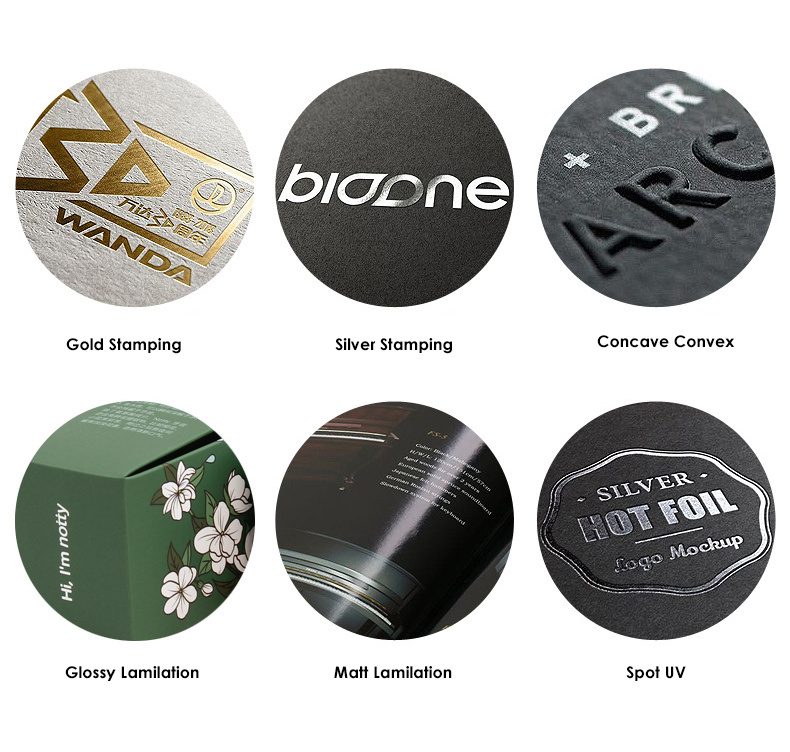

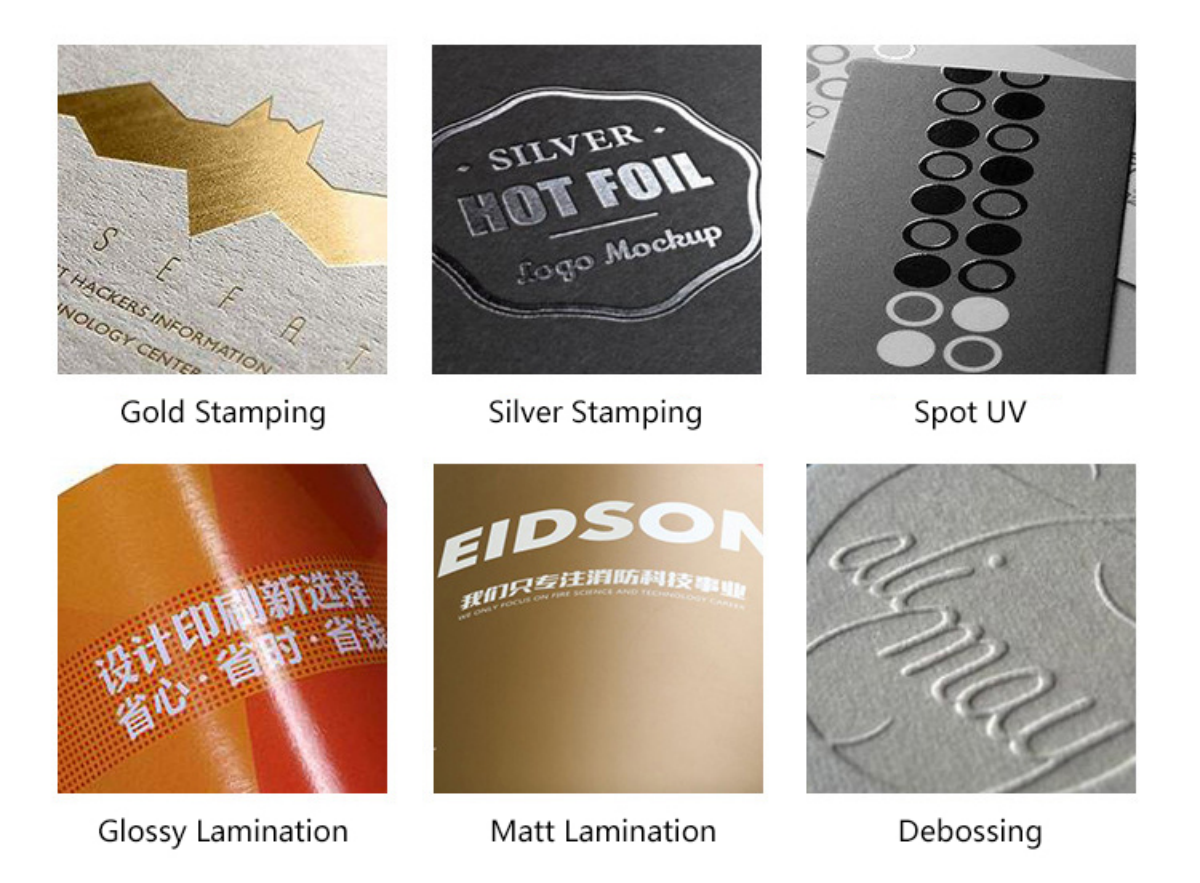

Common Surface Treatment As Follows

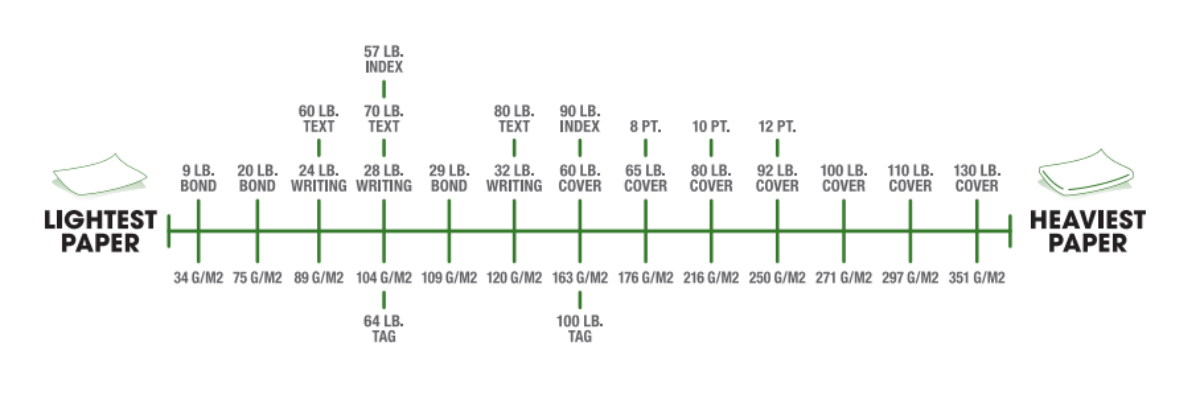

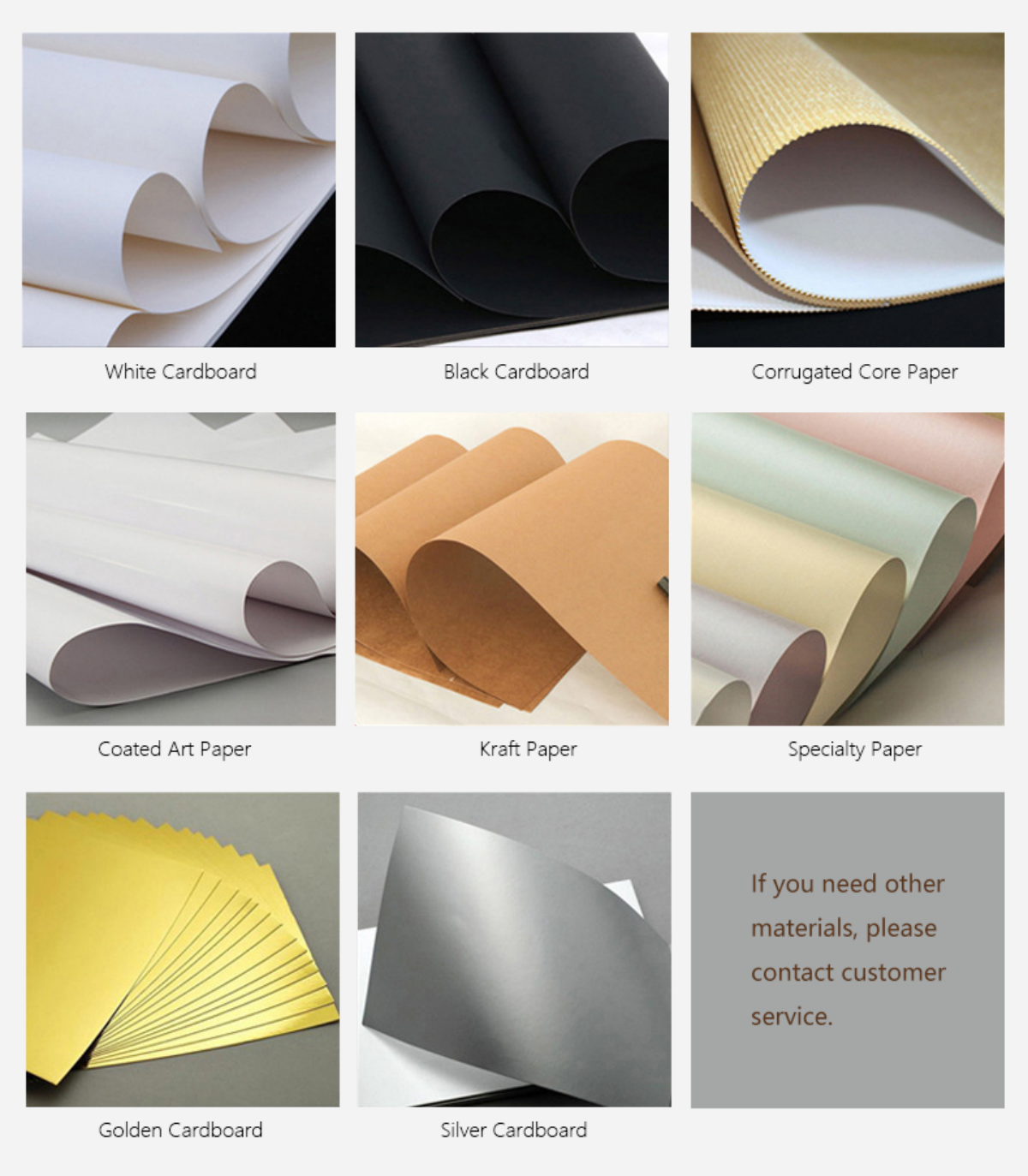

Paper Type

| C1S -White Cardboard PT/G SHEET | ||

| PT | Standard gram | Using gram |

| 7 PT | 161 g | |

| 8 PT | 174 g | 190 g |

| 10 PT | 199 g | 210g |

| 11 PT | 225 g | 230 g |

| 12 PT | 236g | 250g |

| 14 PT | 265 g | 300 g |

| 16 PT | 296 g | 300 g |

| 18 PT | 324g | 350g |

| 20 PT | 345 g | 350 g |

| 22 PT | 379 g | 400g |

| 24 PT | 407 g | 400 g |

| 26 PT | 435g | 450 g |

White card paper

It is better, the price is a little expensive, but the texture and hardness are enough, again the point is white (white board). Powder board paper: white on one side, grey on the other, lower price.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Material Structure and Application

In the highly competitive world of packaging production, efficiency and speed are key factors in meeting customer needs. Ningbo Hexing Packaging Co., Ltd. has introduced advanced fully automatic equipment, including fully automatic self-adhesive pasting machines and tear strip carton gluers, taking an important step towards industry reform. These state-of-the-art machines enable Hexing Packaging to significantly shorten production cycles, thereby delivering high-quality paper color boxes to customers faster.

The addition of a fully automatic self-adhesive, tear-strip and carton-gluing machine has allowed Hexing Packaging to simplify the production process. By automating the application of non-stick adhesives, tear strips and box gluing, the company has been able to reduce irregularities and eliminate the slow manual work previously required. This not only ensures higher quality standards, but also allows color boxes to be completed ahead of schedule and delivered to customers on time and consistently. The result is a significant increase in production efficiency and a competitive advantage in the market.

Box Type and Finish Surface

These box type are used for reference, it can be customized as well.

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment As Follows