Printing Corrugated Carton Packaging Delivery Mailer Paper Box for Coffee Sweets

Description

The box is printed on one side. Offset printing has the characteristics of fine graphics and rich layers, which can display more printing details.

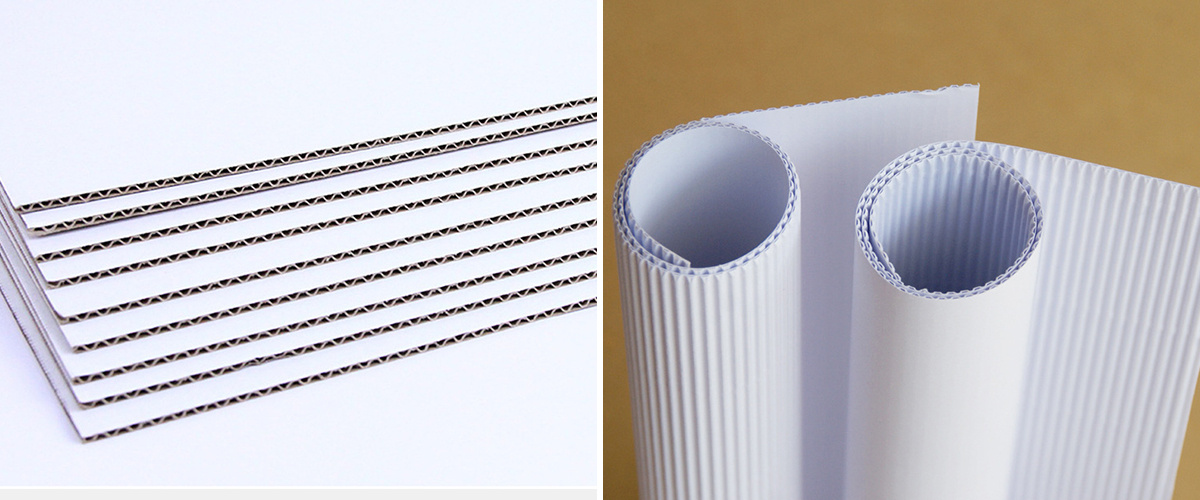

The material is 3 layers of corrugated cardboard to adapt to products of different weights and sizes.

Please communicate and negotiate with the salesperson about the selection of paper materials and printing methods.

Basic Info

|

Product Name |

Express delivery box |

Surface Handling |

Glossy Lamination, Matt Lamination |

|

Box Style |

Folding Packaging Box |

Logo Printing |

Customized Logo |

|

Material Structure |

White Board + Corrugated Paper + White Board/kraft paper |

Origin |

Ningbo |

|

Materials Weight |

250gsm white grayboard/120/170, white kraft, E flute |

Sample |

Accept custom samples |

|

Shape |

Rectangle |

Sample Time |

5-7 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

10-15 days based on quantity |

|

Printing |

Offset Printing |

Transport Package |

Strong 5 ply Corrugated Carton |

|

Type |

Double Side Printing Box |

MOQ |

2000PCS |

Detailed Images

A beautiful box is based on the success of every detail.

We have a professional team to check the structure and printing quality of the box. The cutter mould master will adjust the design and cutter mould according to the different materials.

Please communicate with the salesperson for details.

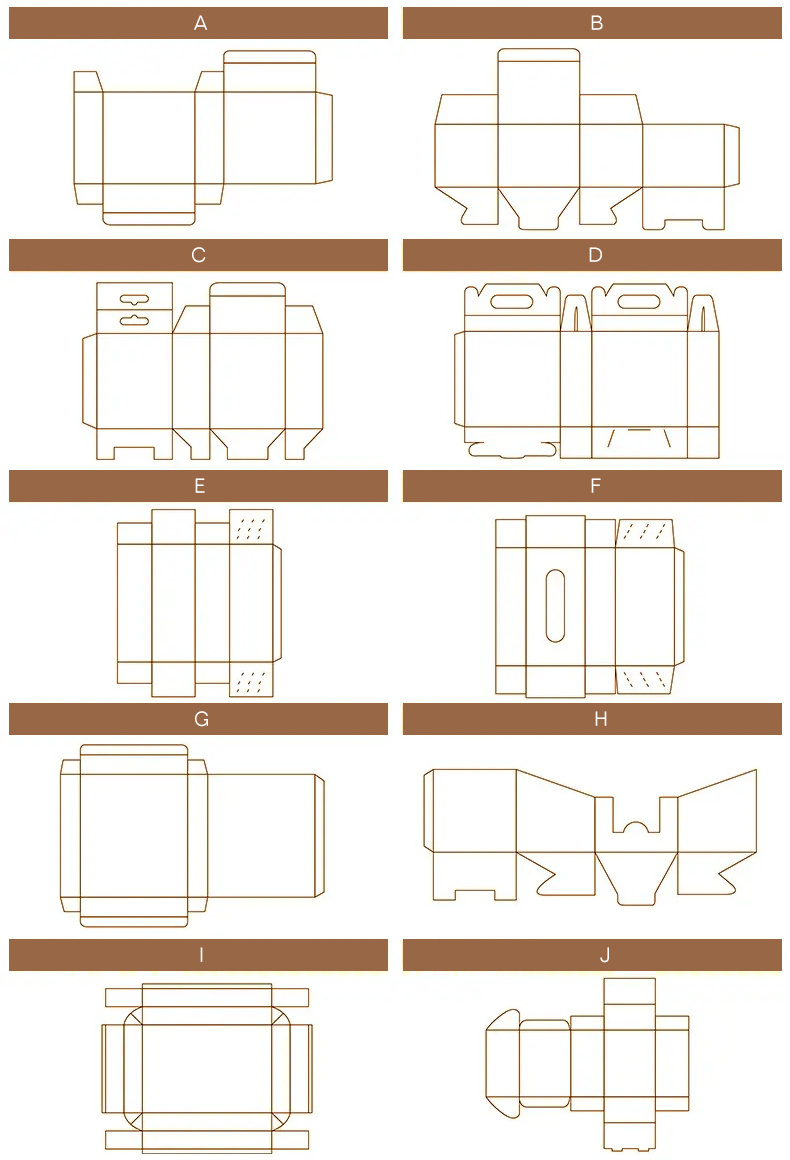

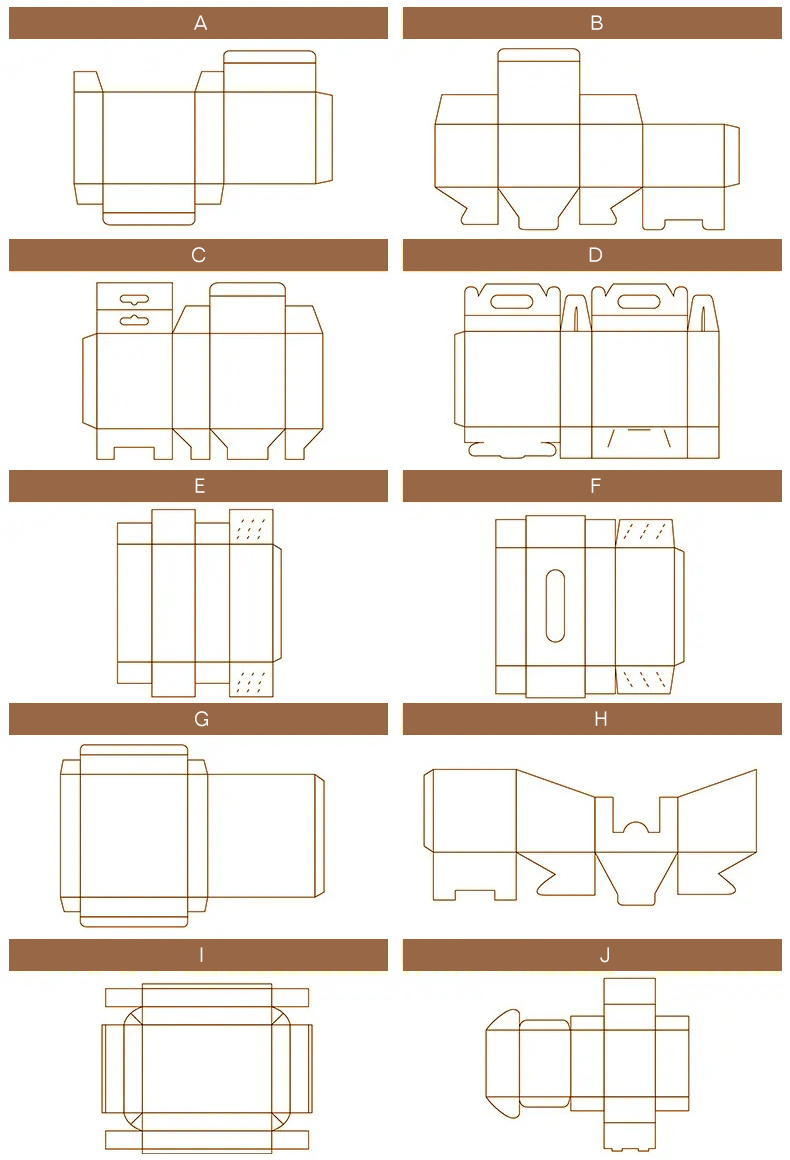

Structure Stretch-out View

Material Structure and Application

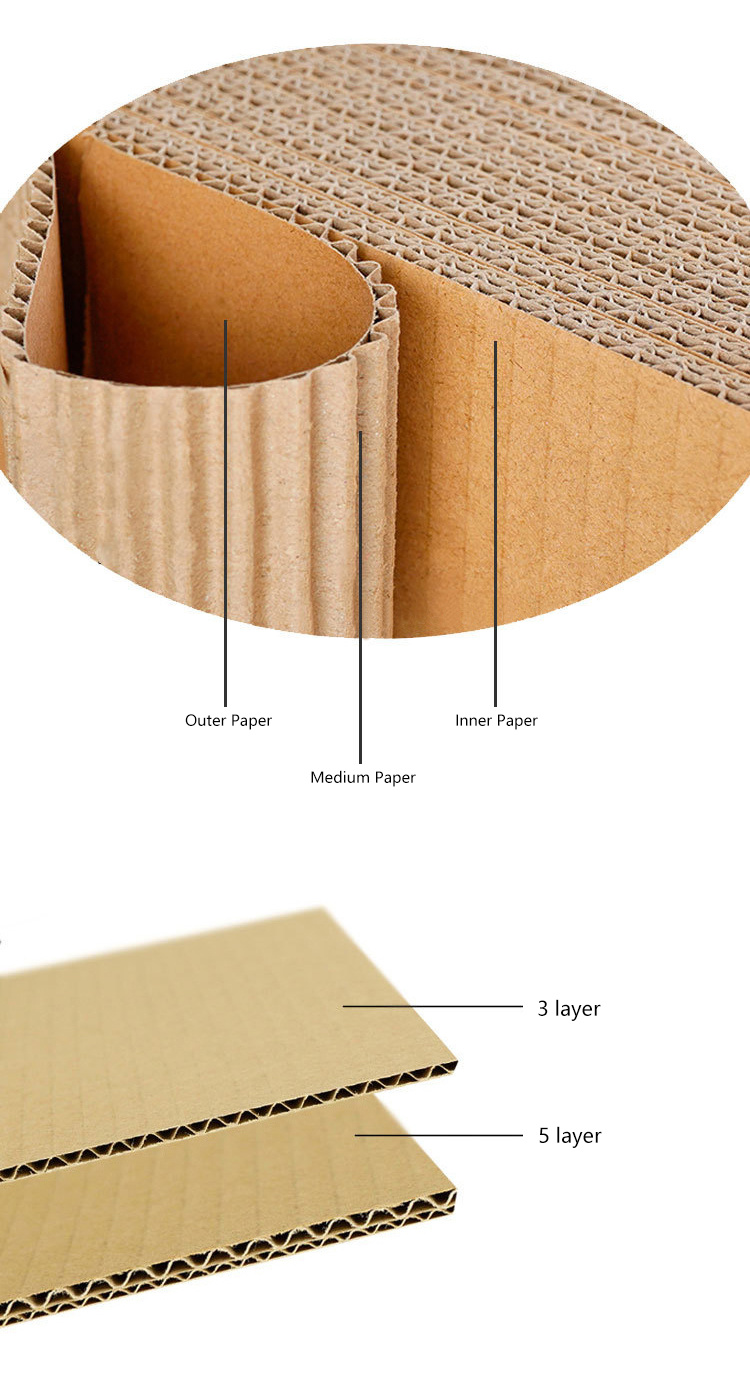

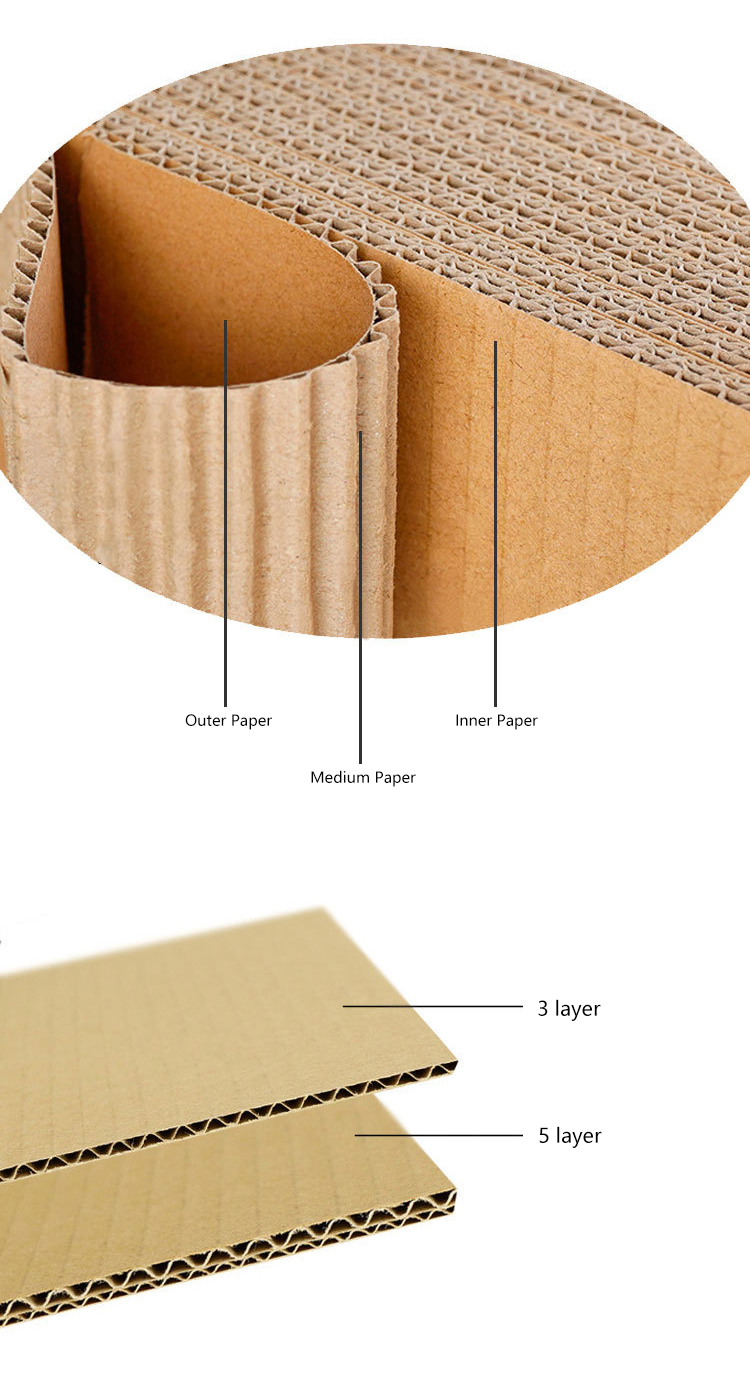

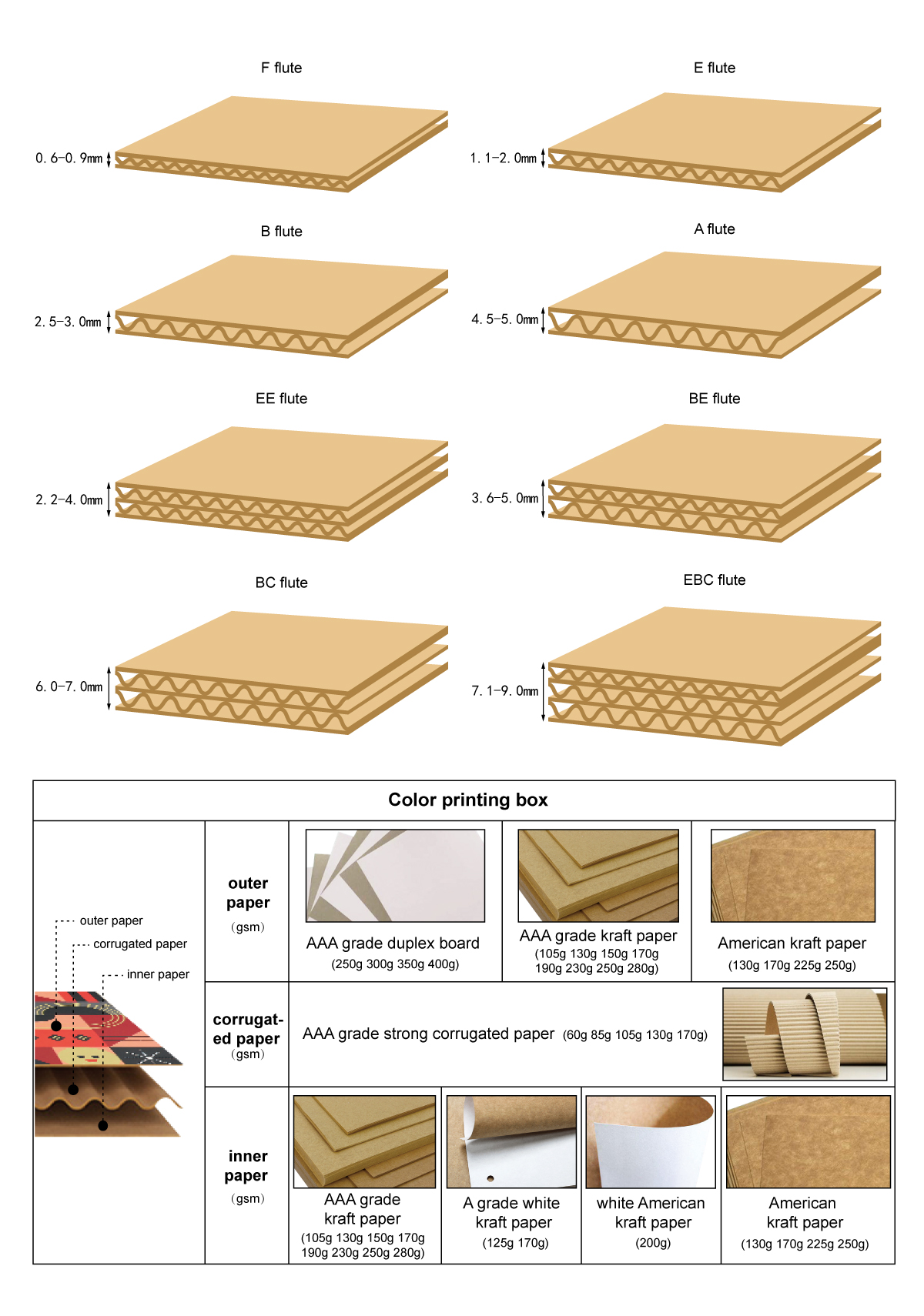

Three types of paper make up the corrugated box's material: exterior paper, medium paper, and inside paper.

The three parts of the material can be customized according to the size and weight of the product. Both the outer paper and the inner paper can be designed with patterns.

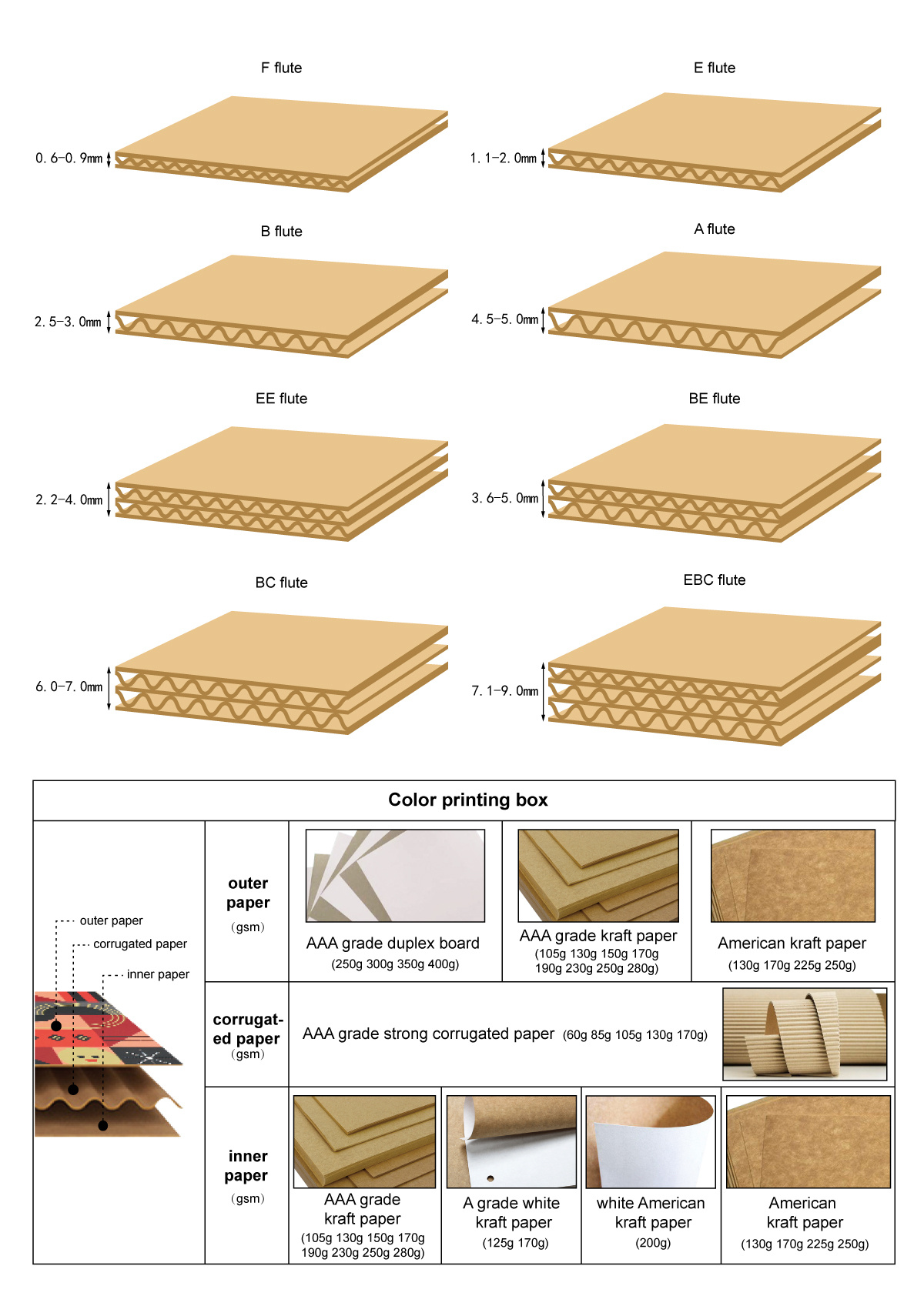

The commonly used materials of outer paper and inner paper are as follows

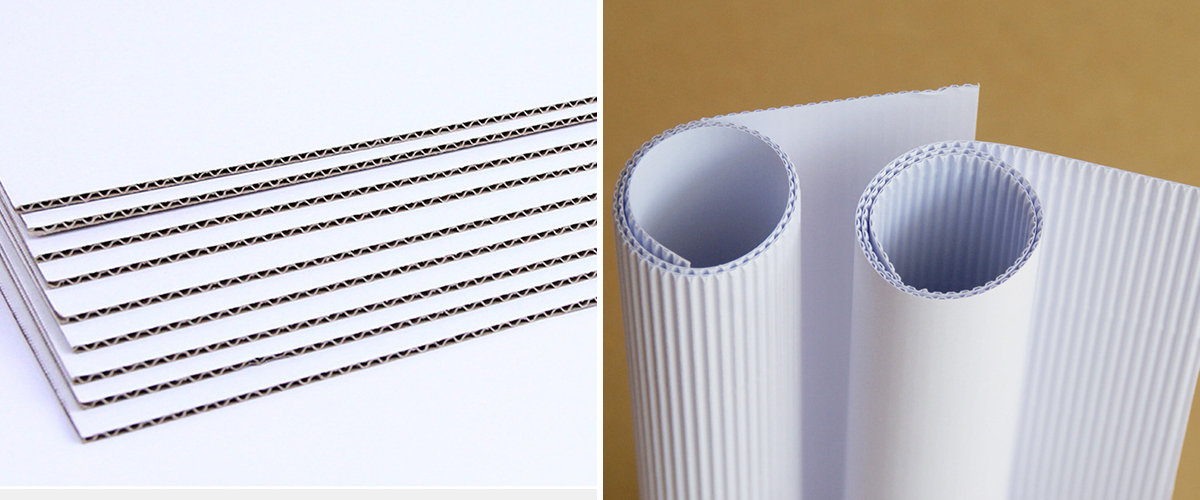

The medium paper is white corrugated cardboard with the following structure.

Corrugated Paperboard Structure Diagram

Packaging Applications

This type of box is widely used in e-commerce.

Box Type and Finish Surface

The box type as follow

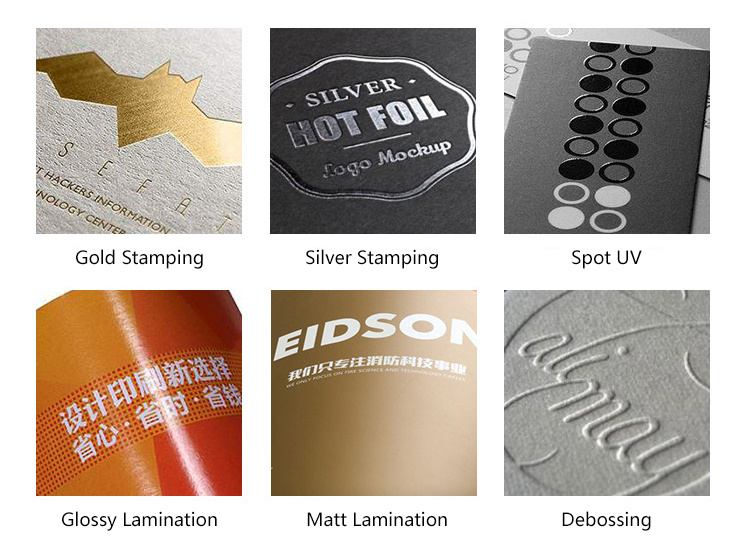

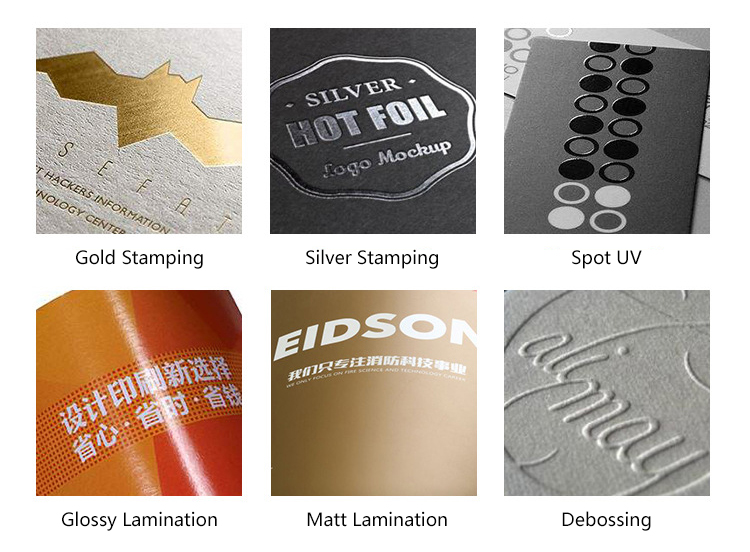

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment as Follows

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Three types of paper make up the corrugated box’s material: exterior paper, medium paper, and inside paper.

The three parts of the material can be customized according to the size and weight of the product. Both the outer paper and the inner paper can be designed with patterns.

The commonly used materials of outer paper and inner paper are as follows.

The medium paper is white corrugated cardboard with the following structure.

Corrugated Paperboard Structure Diagram

Packaging Applications

This type of box is widely used in e-commerce.

The box type as follow

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment as Follows