Single printed strong corrugated mailer boxes for package kitchen ware

Description

This is a 3 layers B-flute corrugated paper box, the top lid is full overlap, and the bottom is self lock. It’s a common packaging for fry pans. Printing is customized, box dimensions depends on size of pans. Glossy surface, matte surface, hot stamping, spot UV both can be done.

Basic Info.

| Product Name | Fry pans packaging box | Surface Treatment | Matte Lamination, etc. |

| Box Style | Product box | Logo Printing | Customized Logo |

| Material Structure | 3 layers corrugated board. | Origin | Ningbo city, China |

| Weight | 32ECT, 44ECT, etc. | Sample type | Printing sample, or no print. |

| Shape | Rectangle | Sample Lead Time | 2-5 working days |

| Color | CMYK, Pantone color | Production Lead Time | 12-15 natural days |

| Printing mode | Offset Printing | Transport Package | Standard export carton |

| Type | One-sided Printing Box | MOQ | 2,000PCS |

Detailed Images

These details are used to show the quality, such as materials, printing and surface treatment.

Detailed Images

These details are used to show the quality, such as materials, printing and surface treatment.

Material Structure and Application

Corrugated paperboard can be divided into 3 layers, 5 layers and 7 layers according to the combined structure.

The thicker “A Flute” corrugated box has better compressive strength than "B Flute" and "C Flute".

“B Flute” corrugated box are suitable for packing heavy and hard goods, and are mostly used for packing canned and bottled goods. "C Flute" performance is close to "A Flute". "E Flute" has the highest compression resistance, but its shock absorption capacity is slightly poor.

Corrugated Paperboard Structure Diagram

Corrugated Paperboard Structure Diagram

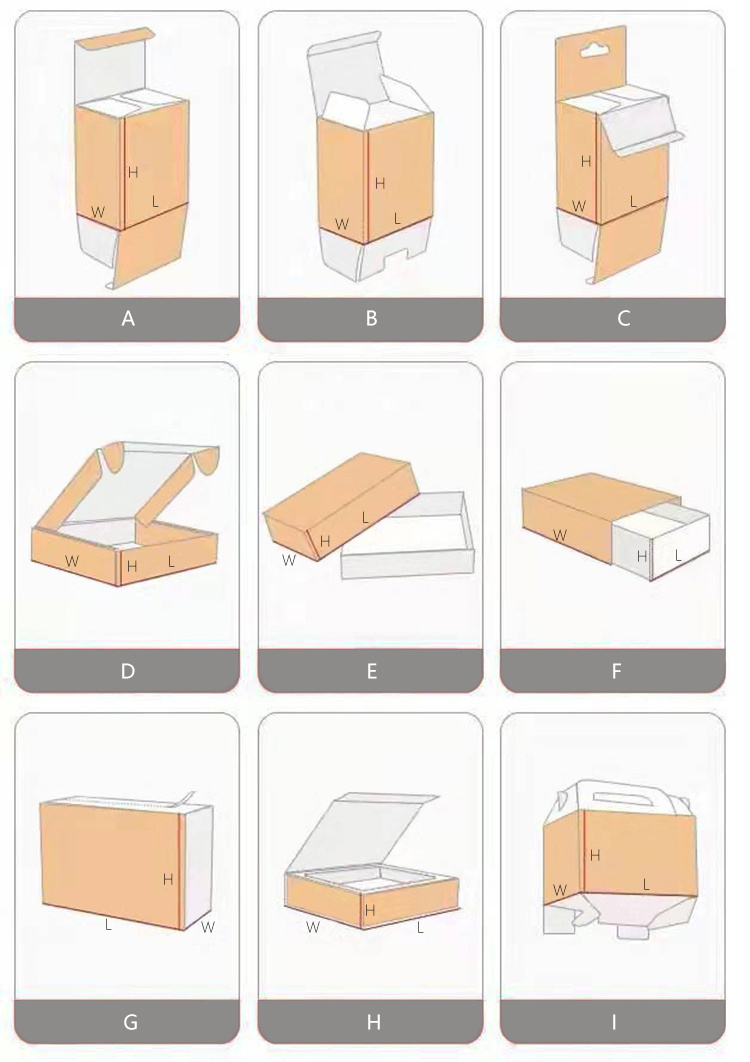

Box Type and Surface Treatment

These box type are used for reference, it can be customized as well.

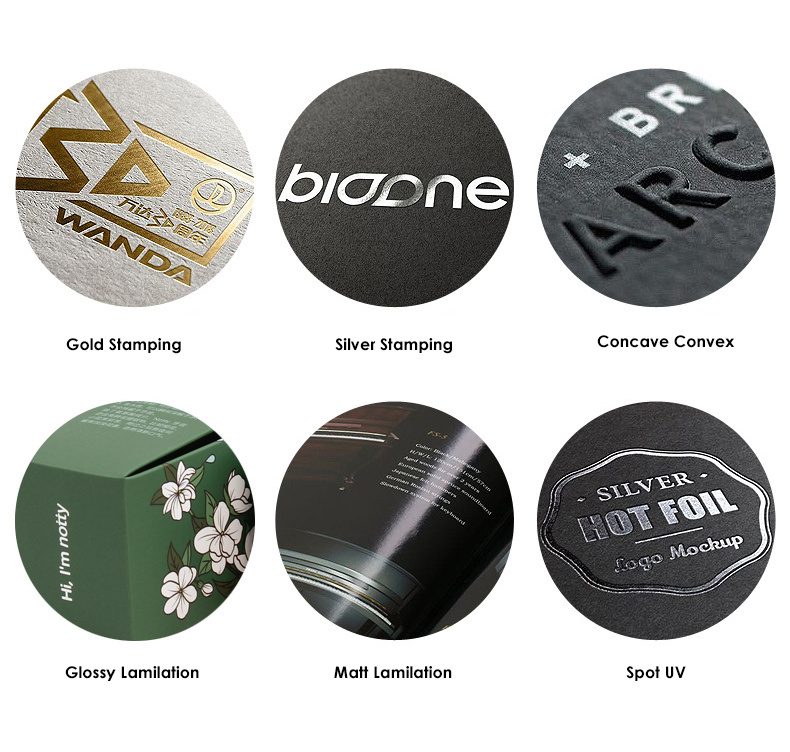

Common Surface Treatment As Follows

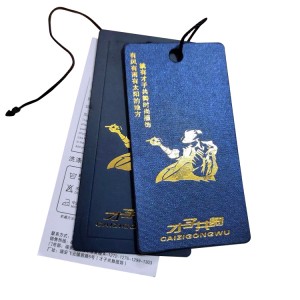

Paper Type

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Material Structure and Application

Packaging is an important part of any business and finding the right printed paper packaging manufacturer can be a challenging task. Fortunately, Ningbo Hexing Packaging Co., Ltd. is here to meet your needs with exceptional service and high-quality packaging solutions.

At Ningbo Hexing Packaging Co., Ltd., we take pride in providing the best packaging products. Our factory covers an area of more than 5000 square meters, with an annual output value of more than 38 million US dollars. Our location is only 75 kilometers away from the bustling Ningbo port, ensuring efficient and convenient transportation.

We have specialized in packaging manufacturing for many years and our experience allows us to fully understand our customers’ wants and needs. Our professional team is here to work with you to create custom packaging to ensure your products stand out.

Box Type and Finish Surface

These box type are used for reference, it can be customized as well.

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment As Follows