RETF Structure Fit Low Height OEM Design Kraft Colorful Corrugated Double Sides Printing Carton Delivery Shipping Paper Gift box

Description

One step assemble structure to package easily, and can be one piece of corrugated board when shipping,

which reduce much volume and shipping fee.

Flexo printing, offset printing inside & outside, making customize design.

The material is strong corrugated paperboard in 3 ply/5 ply,

to fit different weight and size for long distance shipping.

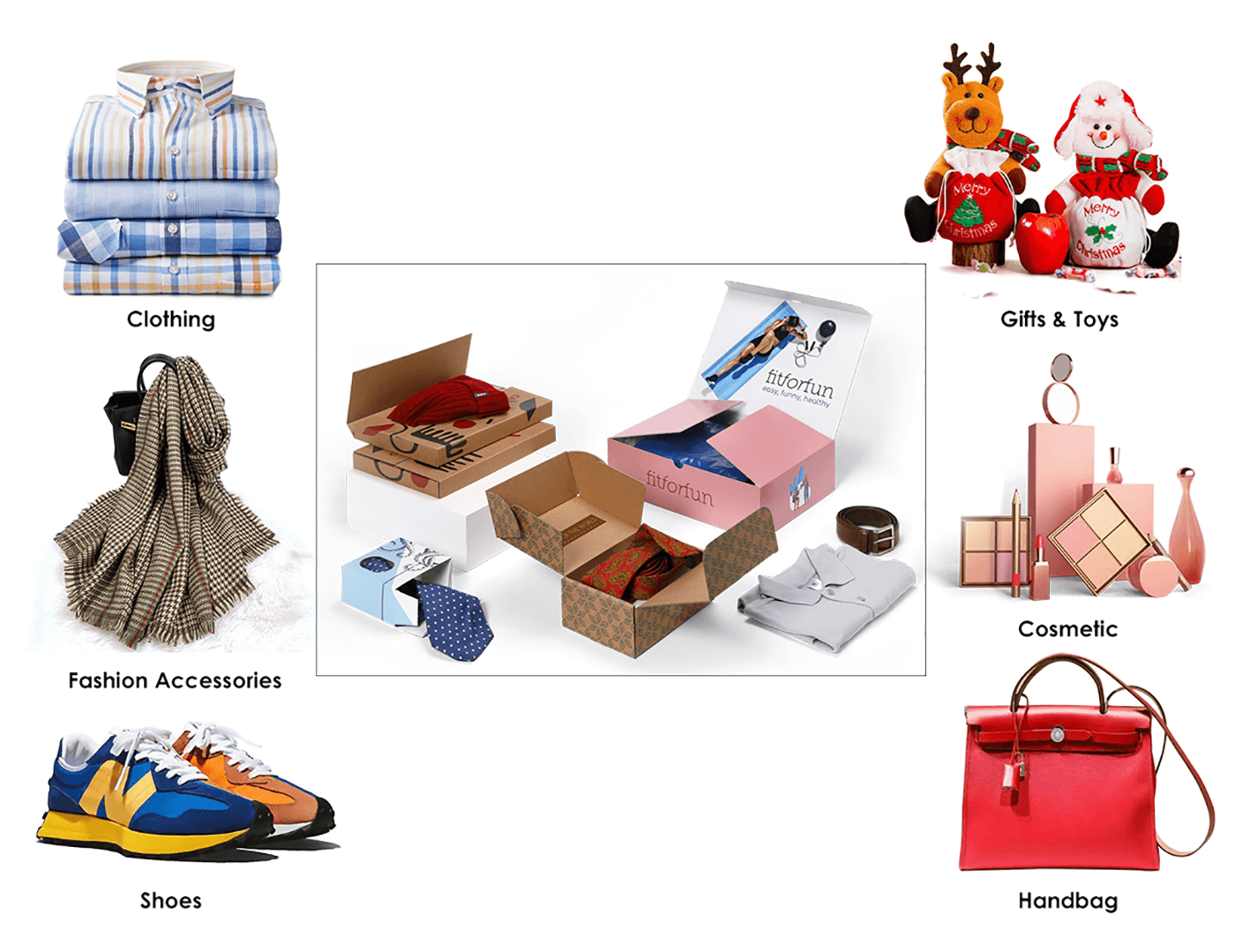

It can be used for shipping, gifts, logistics packaging.

Basic Info.

|

Product Name |

Two-sided Printed Corrugated Packaging |

Surface Handling |

No Lamination |

|

Box Style |

RETF |

Logo Printing |

Customized Logo |

|

Material Structure |

Kraft Corrugated Board, Kraft Paper + Corrugated Paperboard |

Origin |

Ningbo |

|

Weight |

0.2-0.5kg |

Sample |

Accept custom samples |

|

Shape |

Rectangle |

Sample Time |

5-8 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

8-12 days based on quantity |

|

Printing |

flexo Printing, Offset Printing |

Transport Package |

Strong 3 ply/5 ply Corrugated Carton |

|

Type |

Single /Two-sided Printing Box |

MOQ |

2000PCS |

Package size per unit product:

RETF Box 165-external dimension: L208×W110×H70mm;

Gross weight per unit product:92 gram weight;

RETF Box 176-external dimension: L200×W130×H100mm;

Gross weight per unit product:165 gram weight;

Detailed Images

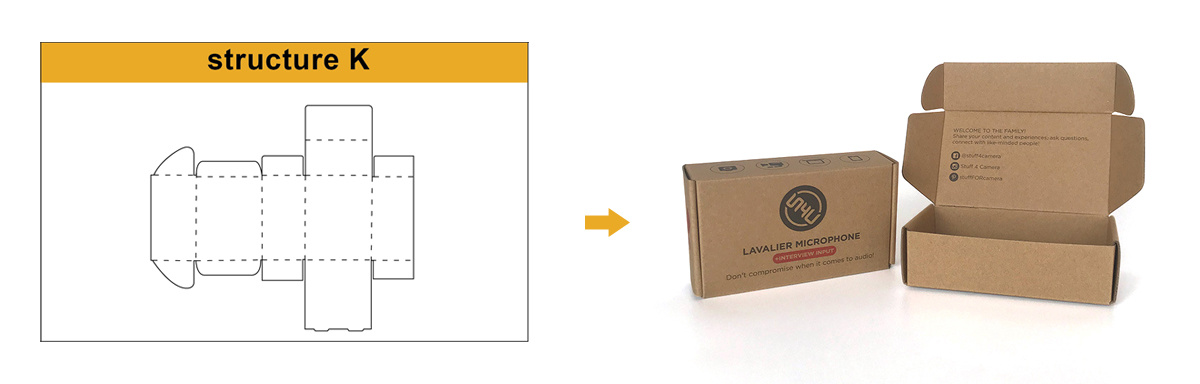

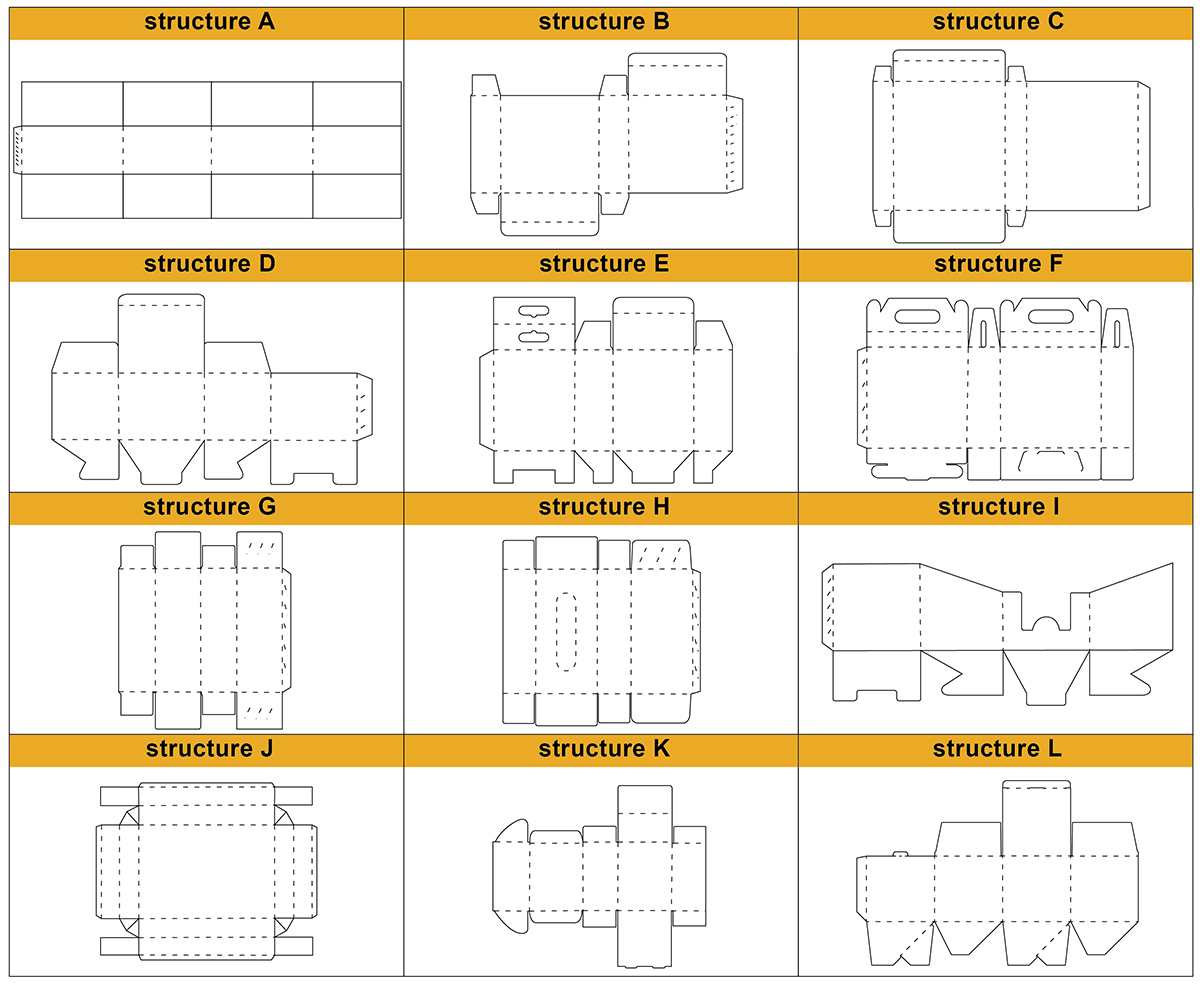

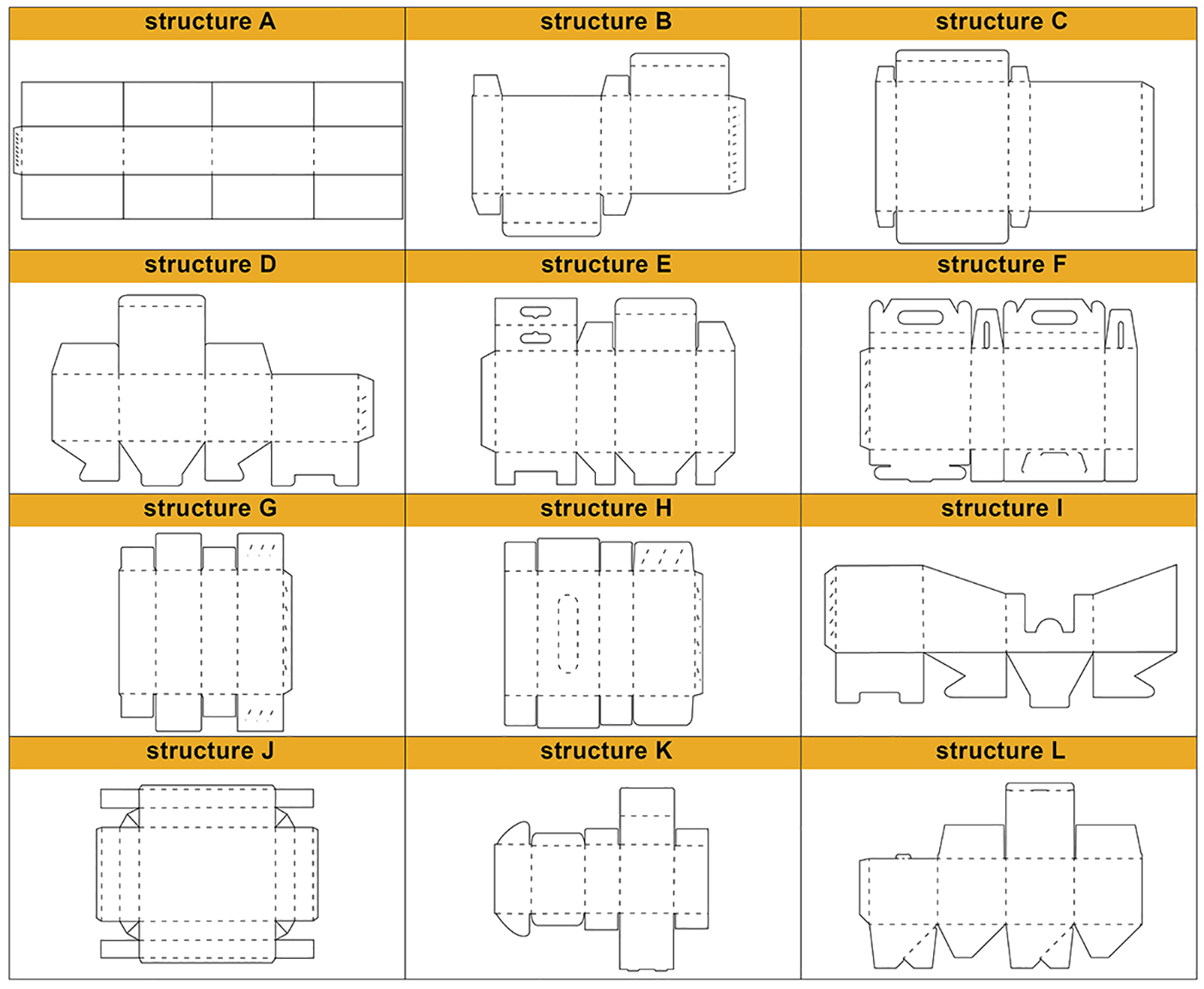

RETF, structure K, our designer will draw box based on your product size or external size you need by wealth experience. This structure fit to height is lower than length &width.

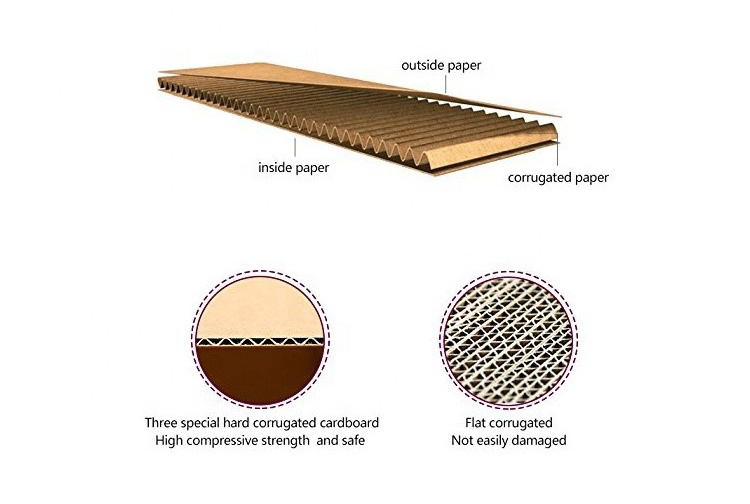

Material Structure and Application

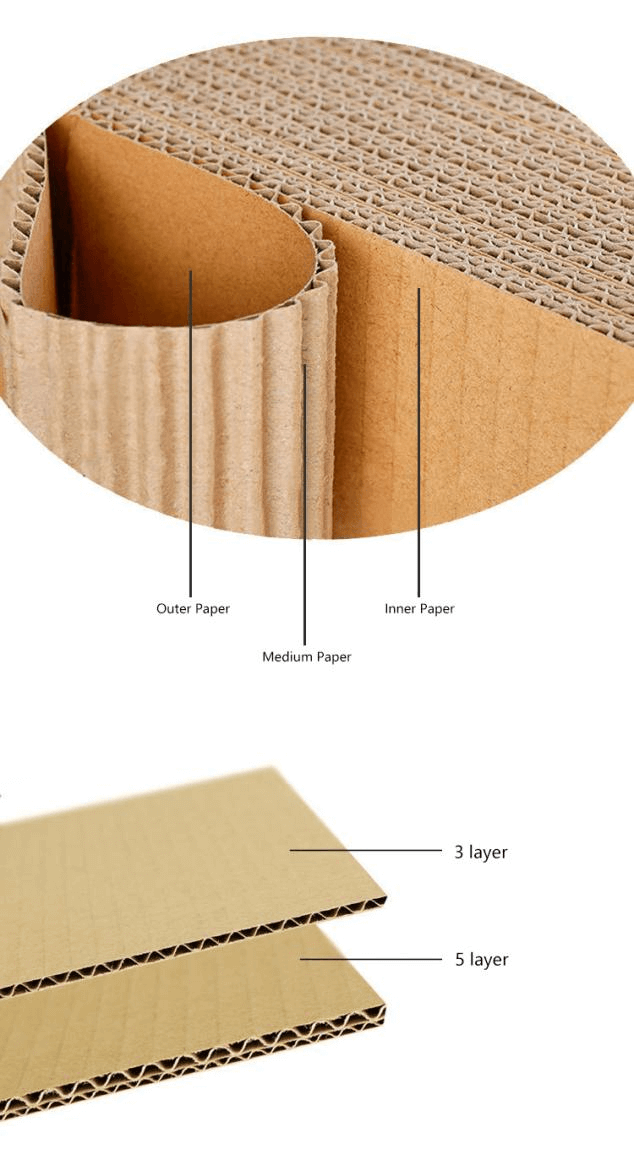

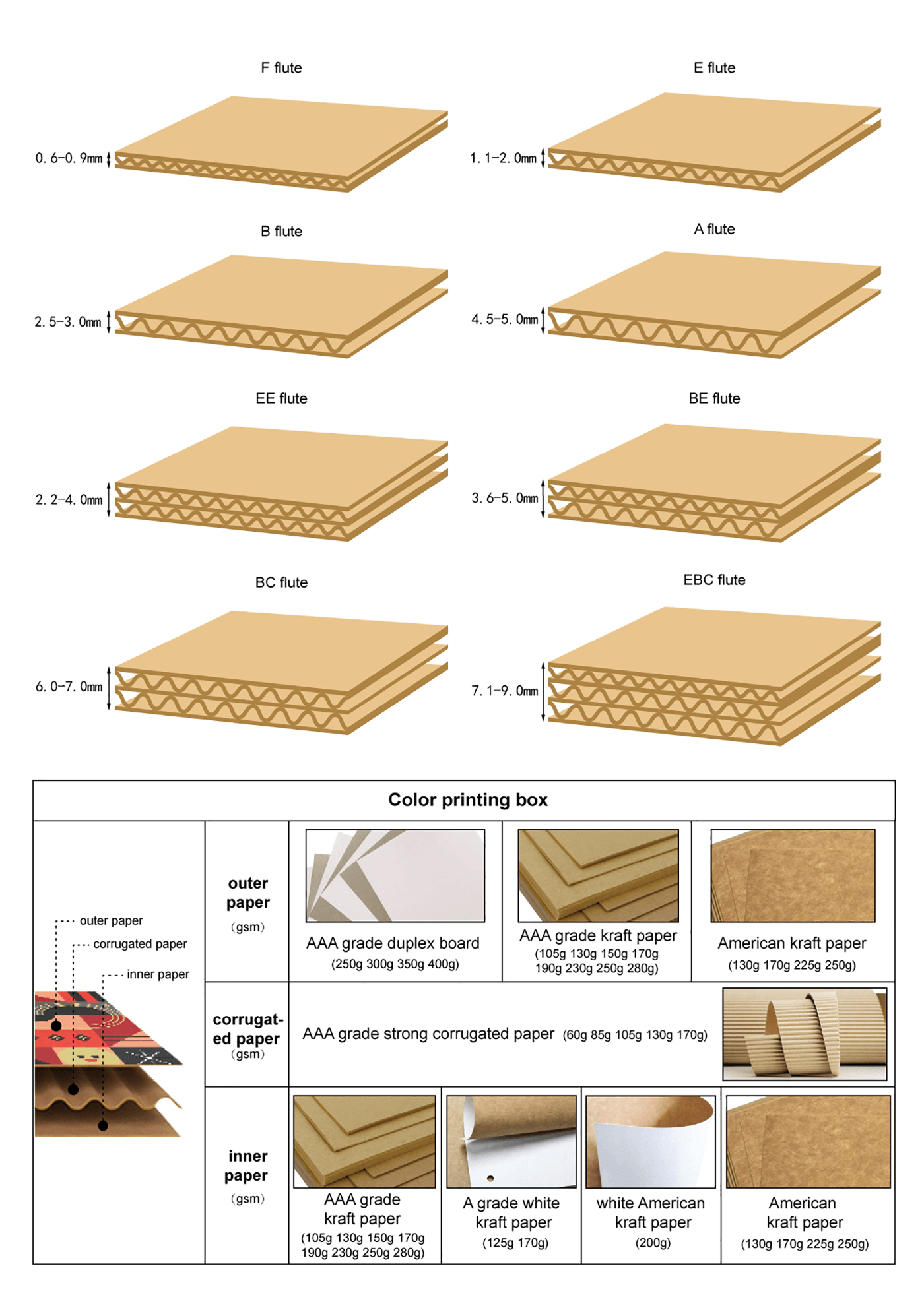

Corrugated paperboard can be divided into 3 layers, 5 layers and 7 layers according to the combined structure.

Three parts as outside paper, corrugated paper and inside paper.

Three parts can be as customized size and weight. Outside & inside paper can be printed OEM design and color.

Corrugated Paperboard Structure Diagram

Packaging Applications

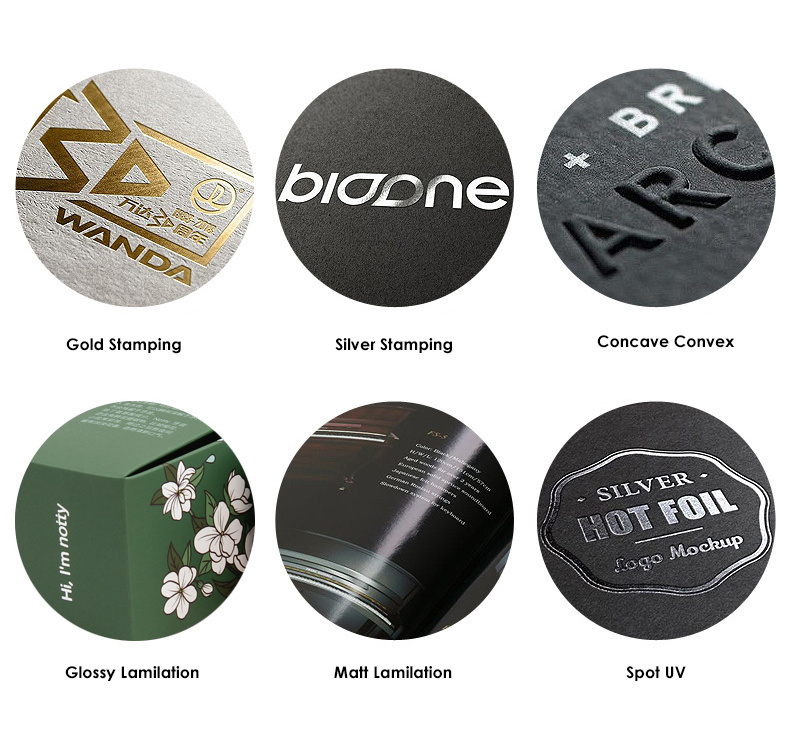

Box Type and Finish Surface

The box type as follow

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment as Follows

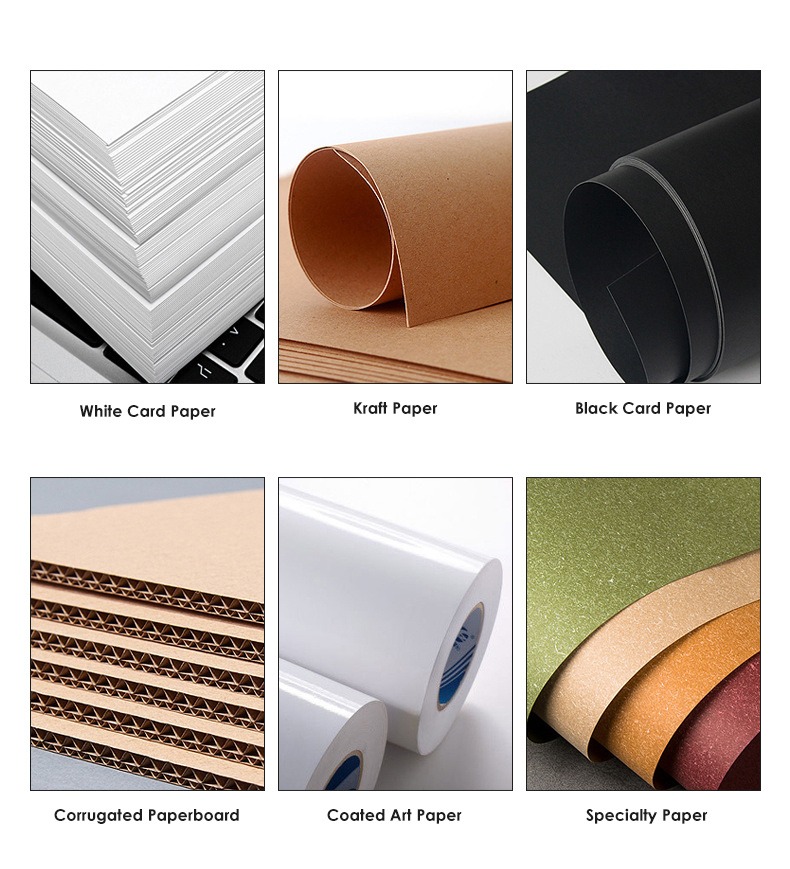

Paper Type

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Black Card Paper

Black cardboard is colored cardboard. According to different colors, it can be divided into red card paper, green card paper, etc. Its biggest drawback is that it can not print color, but it can be used for bronzing and silver stamping. The most commonly used is white card.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for printing advanced picture books, calendars and books, etc.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Ⅰ Material Structure

Corrugated board

◆Corrugated board is a multi-layer adhesive body, which is composed of at least one layer of corrugated core paper inter layer (commonly known as “pit sheet”, “corrugated paper”, “corrugated core”, “corrugated base paper”) and one layer of cardboard (also known as “box board paper”, “box board”).

◆It has high mechanical strength and can resist collision and fall in the process of handling. The actual performance of corrugated cardboard depends on three factors: the characteristics of the core paper and cardboard, and the structure of the carton itself.

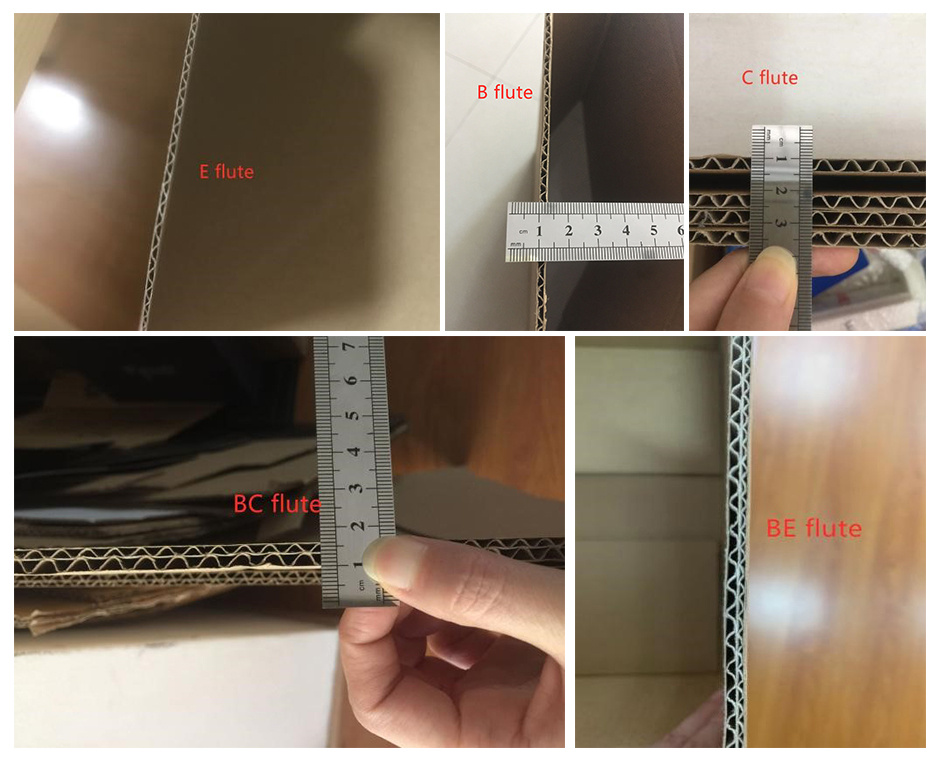

Corrugated paper

◆Corrugated paper is made of hanging paper and corrugated paper formed by corrugated roller processing and bonding board.

◆Generally divided into single corrugated board and double corrugated board two categories, according to the size of corrugated is divided into: A, B, C, E, F five types.

Ⅱ. Application Scenarios

◆Corrugated cardboard

Corrugated cardboard began in the late 18th century, the early 19th century because of its light weight and cheap, wide use, easy to make, and can be recycled or even reused, so that its application has a significant growth. By the beginning of the 20th century, it had been widely used to make packaging for a wide variety of commodities. Because the packaging container made of corrugated cardboard has its unique performance and advantages to beautify and protect the goods inside, so it has achieved great success in the competition with a variety of packaging materials. So far, it has become one of the main materials for making packaging containers, which has been used for a long time and presented rapid development.

◆Corrugated boxes

Corrugated boxes are made of corrugated cardboard, is the most widely used paper container packaging, widely used in transportation packaging.

Corrugated box is widely used because it has many unique advantages:

① good cushioning performance.

② Light and firm.

③ Small size.

④ Sufficient raw materials, low cost.

⑤ Easy to automate production.

⑥ Low cost of packaging operations.

⑦ can pack a variety of items.

⑧ less metal consumption.

⑨ Good printing performance.

⑩ Recyclable and reusable

Ⅰ. Box Type

◆Carton (hard paper case)

Carton is the most widely used packaging products. According to different materials, there are corrugated cartons, single-layer cardboard boxes, etc., with various specifications and models.

◆Carton commonly has three layers, five layers, seven layers are less used, each layer is divided into inner paper, corrugated paper, core paper, face paper. Inner& face paper to be brown kraft paper, white greyboard, ivory board, black card, art paper and so on.All kinds of paper color and feel are different, different manufacturers of paper (color, feel) are different.

◆Customized Structure

Carton structure can be customized according to customer requirements.

Common structures are:

①cover type structure,

②shake type structure,

③window type structure,

④drawer type structure,

⑤carrying type structure,

⑥display type structure,

⑦closed structure,

⑧heterogeneous structure and so on.

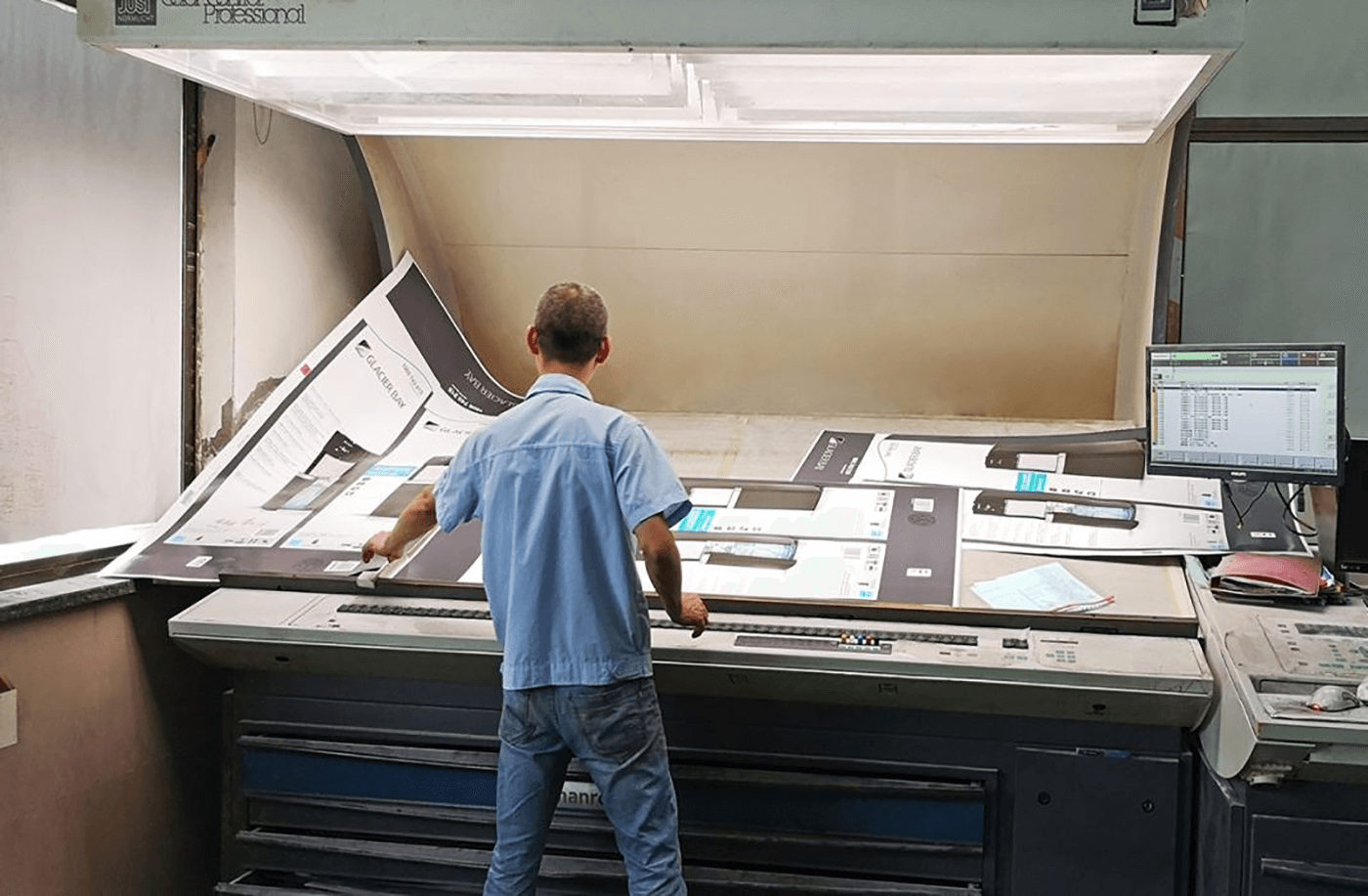

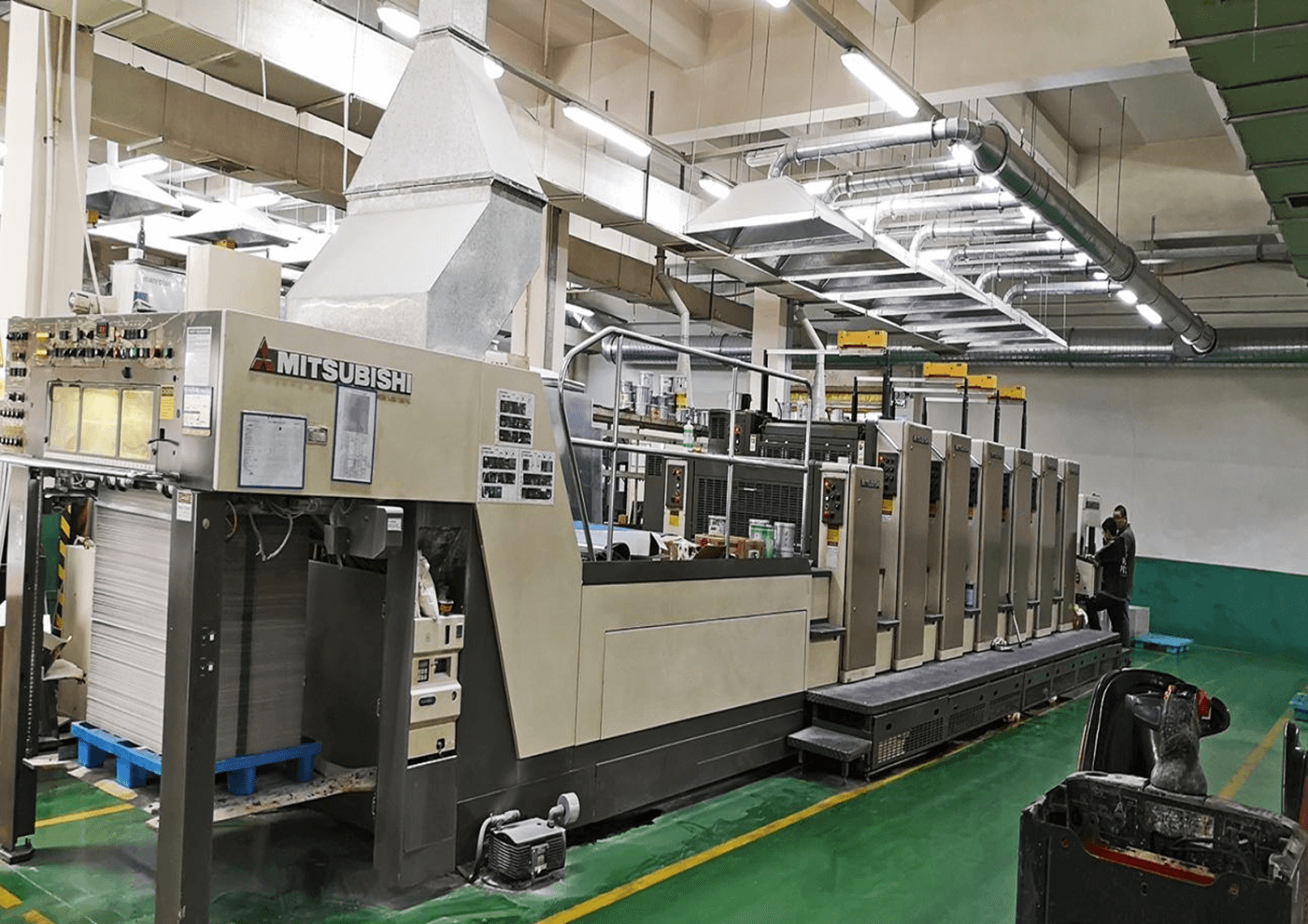

Ⅱ Carton Printing

◆Printing Technology

Common carton printing process Carton printing technology, the process is simple, economical and practical. By the majority of the market carton demand is large, main printing process as follow: offset printing, flexo printing , UV printing , gravure printing process and so on.

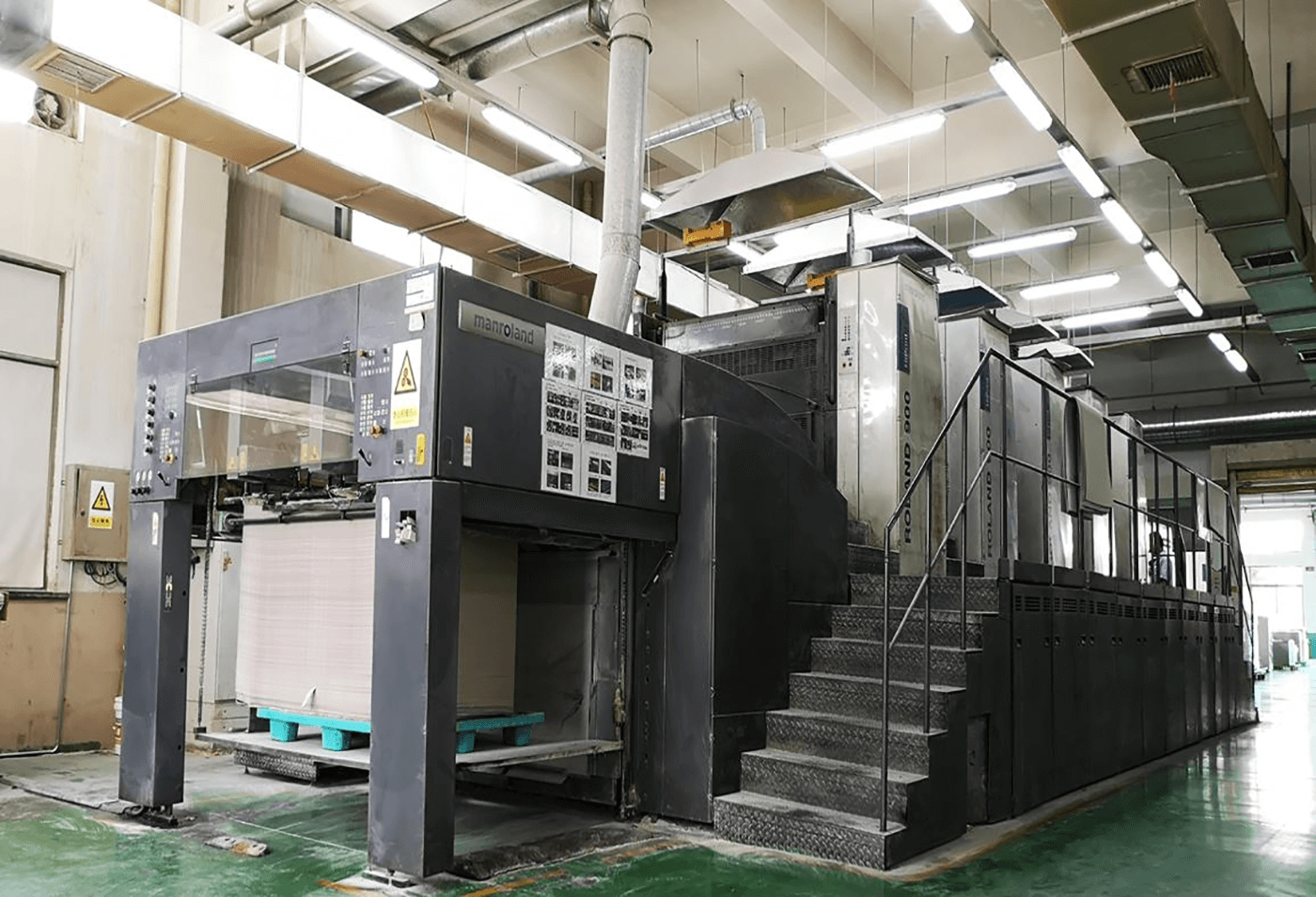

◆Pinting Machine

|

Kind |

Dimension |

|

Octet printing press size |

360*520 MM |

|

Quad press size |

522*760 MM |

|

The size of the folio press |

1020*720mm |

|

1.4M printing press size |

1420*1020mm |

|

1.6M printing press size |

1620*1200mm |

|

1.8M printing press size |

1850*1300mm |

◆ Hexing printing equipment

❶ MITSUBISHI 6- color Offset Press

• Specification of equipment: 1850X1300mm

•Main performance: printing big-size surface paper

•Advantage: automatic setup plate, computer automatically adjusting ink,printing 10000 pieces per hour.

❷ Heidelberg 5-color offset press

• Specification:1030X770mm

❸ Kodak CTP

• (VLF)CTP plate maker

• Specification: 2108X1600mm