Sea Blue Silver Logo Paper Packing Gift Box with Ribbon Handle

Description

Gift box is a practical gift packaging which mainly aims at presenting gifts to relatives and friends to express affection. It is an extension of the social needs of a functional packaging way. Gift box is the embodiment of the soul. we make love gifts or buy love goods to show romantic, mysterious, surprise by paper package. When you slowly open it like open the secret forest in your heart. Gift box expressing to him/her what you want in the mind.This is the meaning of the gift box.

Basic Info.

|

Product Name |

Color Corrugated Gift Box |

Surface Handling |

Glossy lamination, Matte lamination, Spot UV |

|

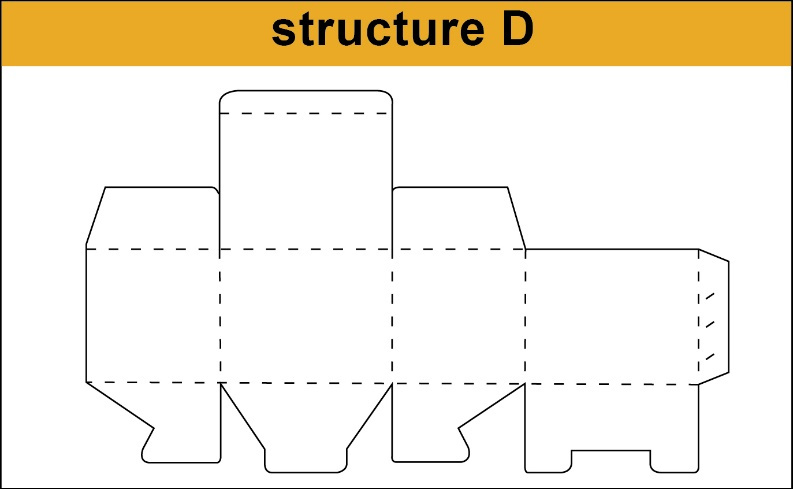

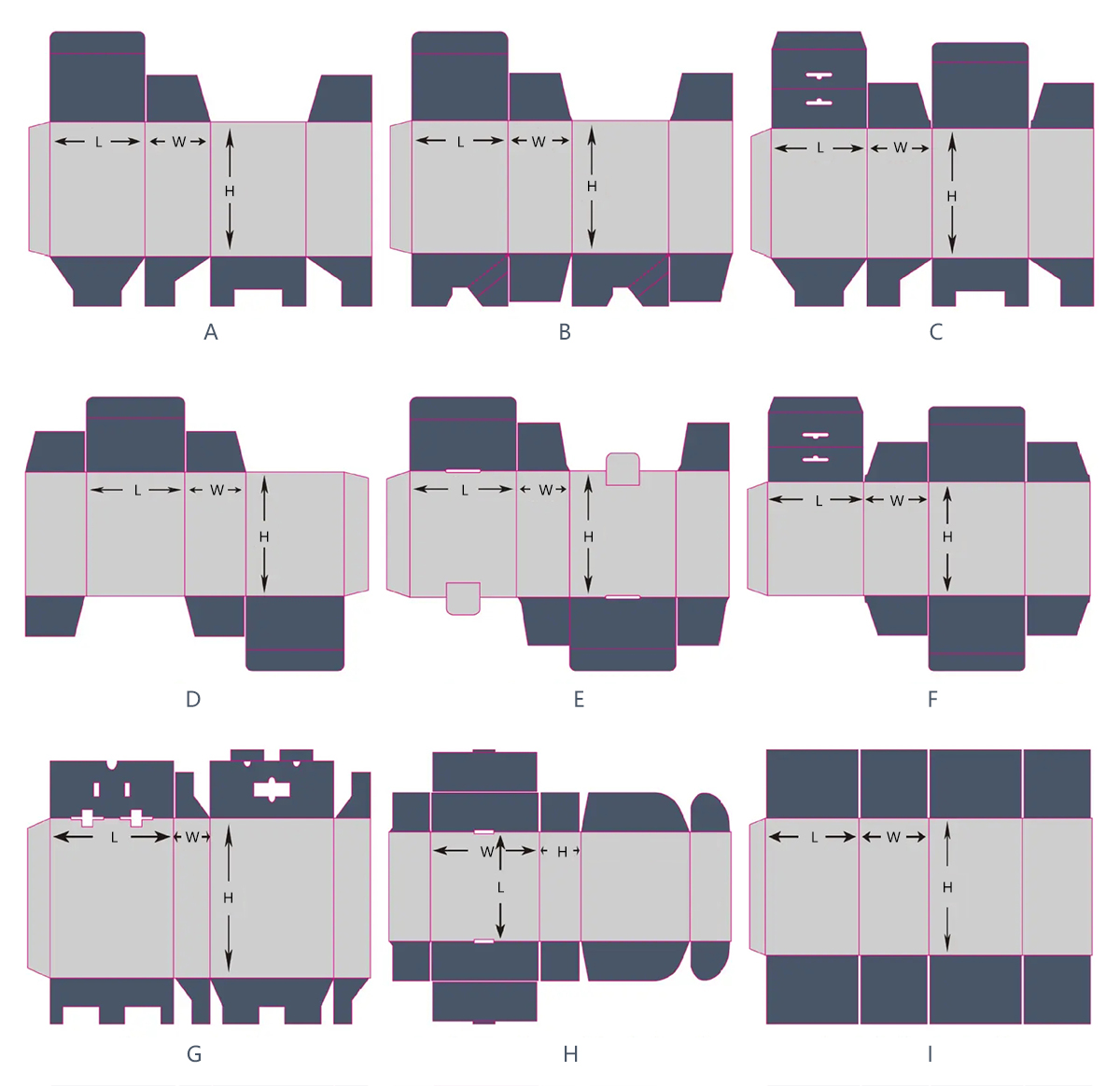

Box Style |

Structure D |

Logo Printing |

Customized Logo |

|

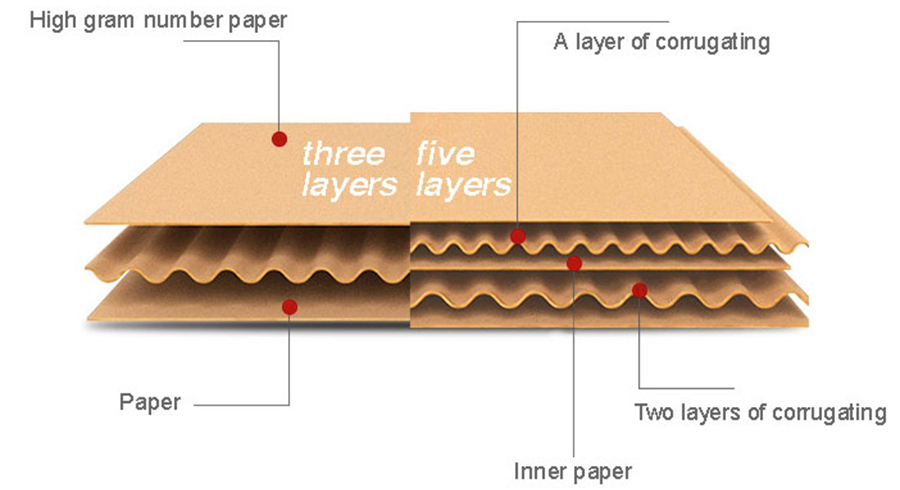

Material Structure |

White Board + Corrugated Paper + White Board/kraft paper |

Origin |

Ningbo,Shanghai port |

|

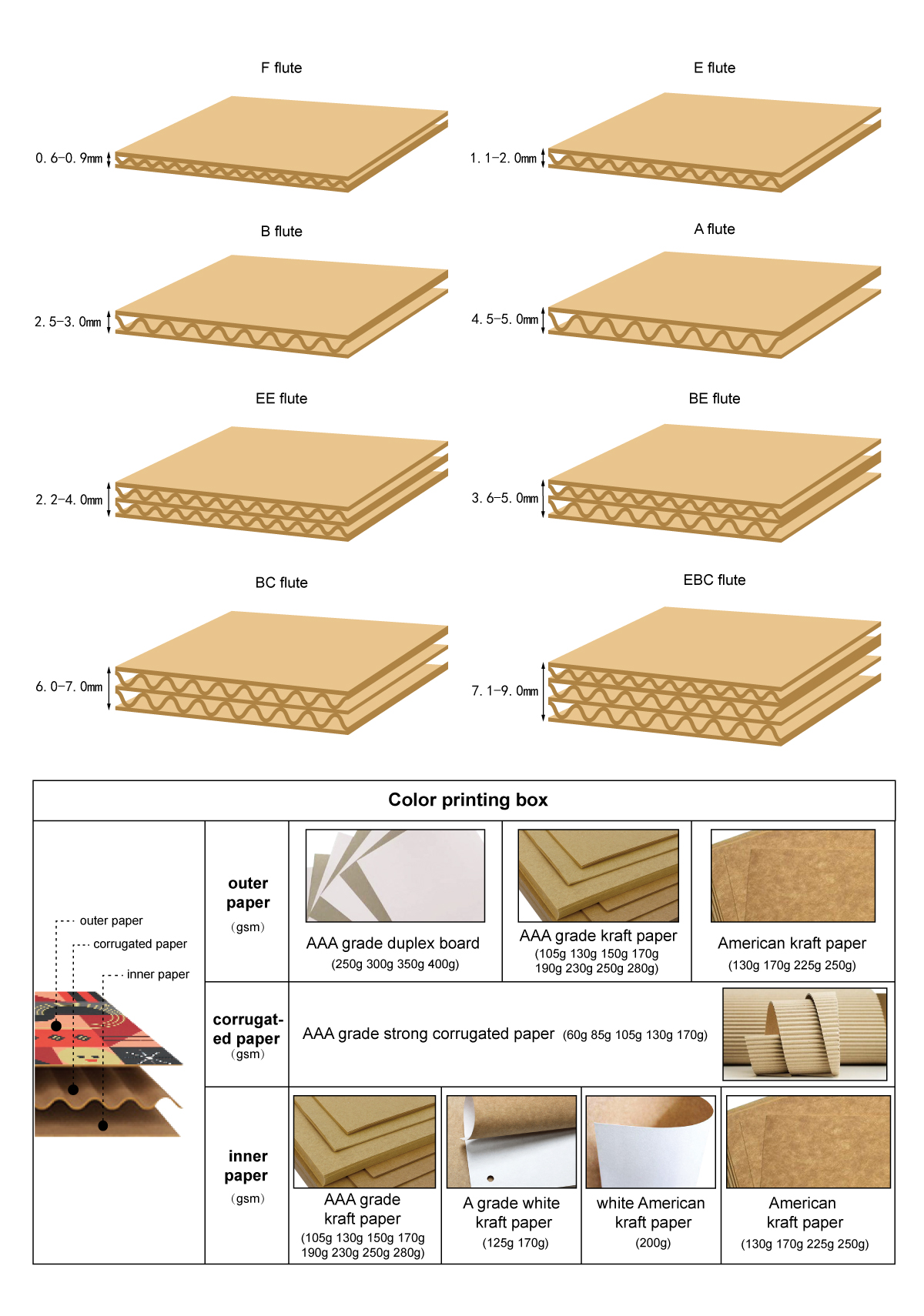

Flute type |

E flute, B flute, BE flute |

Sample |

Accept |

|

Shape |

Rectangle |

Sample Time |

5-8 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

8-12 working days based on quantity |

|

Printing |

Offset Printing |

Transport Package |

By cartons, bundle, pallets |

|

Type |

Single Printing Box |

Shipping |

Sea fright, air freight, express |

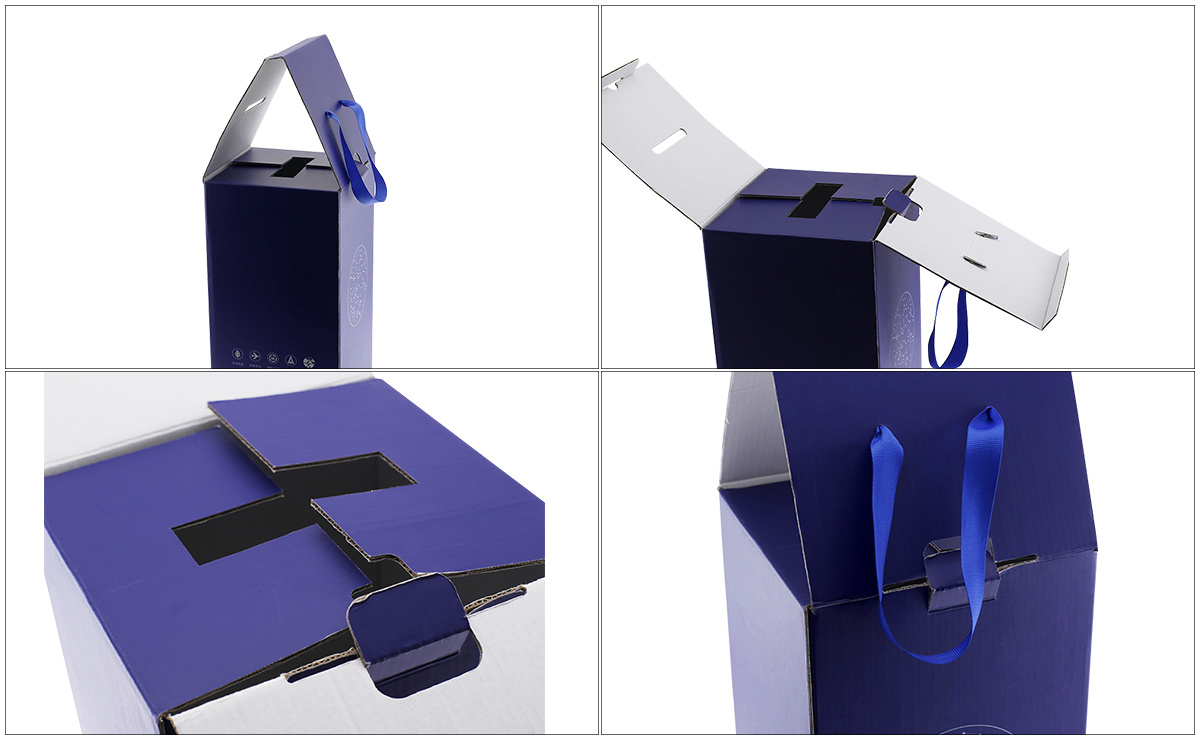

Detailed Images

With the continuous development of The Times, the continuous update of production technology and equipment, people use equipment technology is more sophisticated and the market demand is more fine, the demand for corrugated cardboard is expanding with a very considerable geometric multiple, but in the increasingly fierce market competition, science and technology constantly updated, new packaging materials are constantly developed today, Corrugated cardboard to maintain their own packaging materials in the "elder brother" status, in the research and development of technical equipment, quality performance improvement and product category expansion rich and so on to further improve and development.

Material Structure and Application

♦ Material of paper box & handle

Also known as corrugated cardboard. It is made of at least one layer of corrugated paper and one layer of box board paper (also called box board), which has good elasticity and extensibility. It is mainly used in the manufacture of carton, carton sandwich and other packaging materials for fragile goods. The main use of soil grass pulp and waste paper by pulping, made similar to the original cardboard, and then after mechanical processing rolled into corrugated, and then on its surface with sodium silicate and other adhesive and box board paper bonding.

♦ Corrugated Paper

Corrugated paper is made of hanging paper and corrugated paper formed by corrugated roller processing and bonding board.

generally divided into single corrugated board and double corrugated board two categories, according to the size of corrugated is divided into: A, B, C, E, F five types.

♦ Packaging Applications

Box Type and Finish Surface

• Variety of box designs

Carton is a three-dimensional shape, it is composed of a number of planes moving, stacking, folding, surrounded by a multi-faceted shape. The surface in three-dimensional construction plays the role of dividing space in space. The surface of different parts is cut, rotated and folded, and the surface obtained has different emotions. The composition of the carton display surface should pay attention to the connection between the display surface, side, top and bottom, and the setting of the packaging information elements.

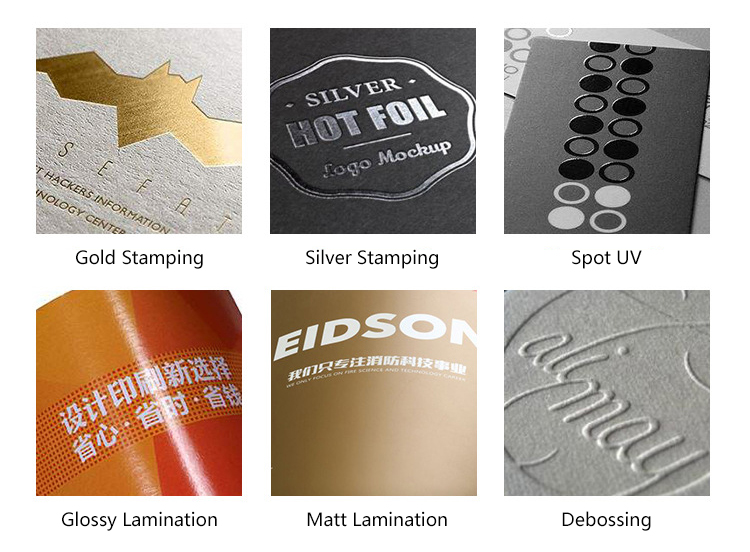

♦ Surface Treatment

Classic surface treatment

❶ Gold stamping ❷ Silver Stamping

Gilding process is to use the principle of hot pressing transfer. The aluminum layer of electrolytic aluminum transfer to the substrate surface to form a special metal effect. Main material used in gilding is electrolytic aluminum foil, so gilding is also called electrolytic aluminum hot stamping.

❸ Debossing ❽ Embossing

Concave is the use of concave template (negative template) through the action of pressure. The surface of the printed matter is imprinted into a sense of depression relief pattern. Printed matter is locally depressed, so that it has a three-dimensional sense, causing visual impact.

Features: Can increase the three-dimensional sense of application range.

Suitable for more than 200g paper, mechanism sense obvious high weight special paper.

Note: with bronzing, local UV process effect is better.If the concave template after heating on the special hot melt paper, it will achieve extraordinary artistic effect.

❹ Matt Lamination ❺ Glossy lamination

Laminating is the plastic film coated with adhesive. Paper as substrate printed matter, after the rubber roller and heating roller pressure together, forming a paper-plastic product.

Covered with matte film, is in the name card surface covered with a layer of frosted texture film;

Coating film, is a layer of glossy film on the surface of the business card.

The coated products, due to its surface more than a layer of thin and transparent plastic film, smooth and bright surface, graphic color more bright. At the same time play the role of waterproof, anti-corrosion, wear resistance, dirty resistance and so on.

❻ Spot UV

Spot UV can be implemented after the film, also can be directly glazing on the print. But in order to highlight the effect of local glazing, It is generally after the printing film, and to cover matte film. About 80% of the local UV glazing products.