Wholesales Color Small Paper Packaging Corrugated Box for Pet Products

Description

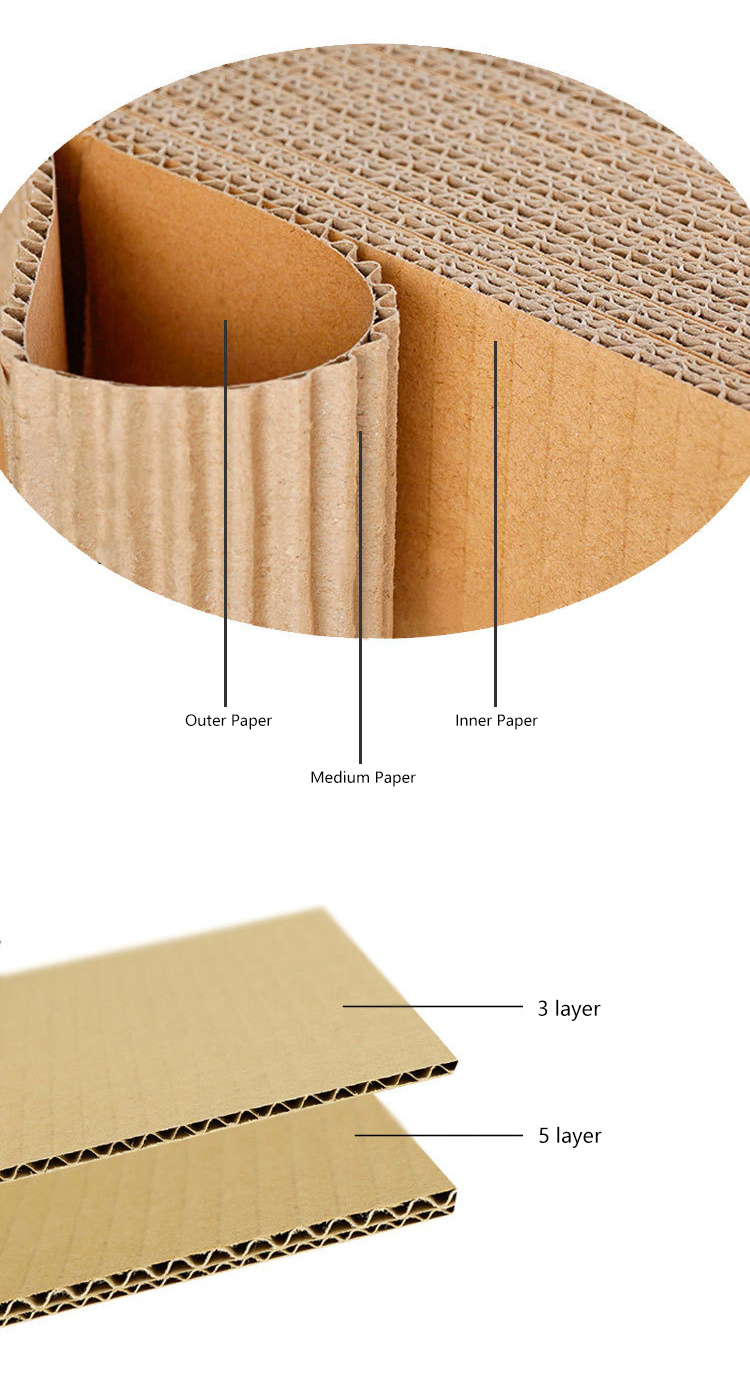

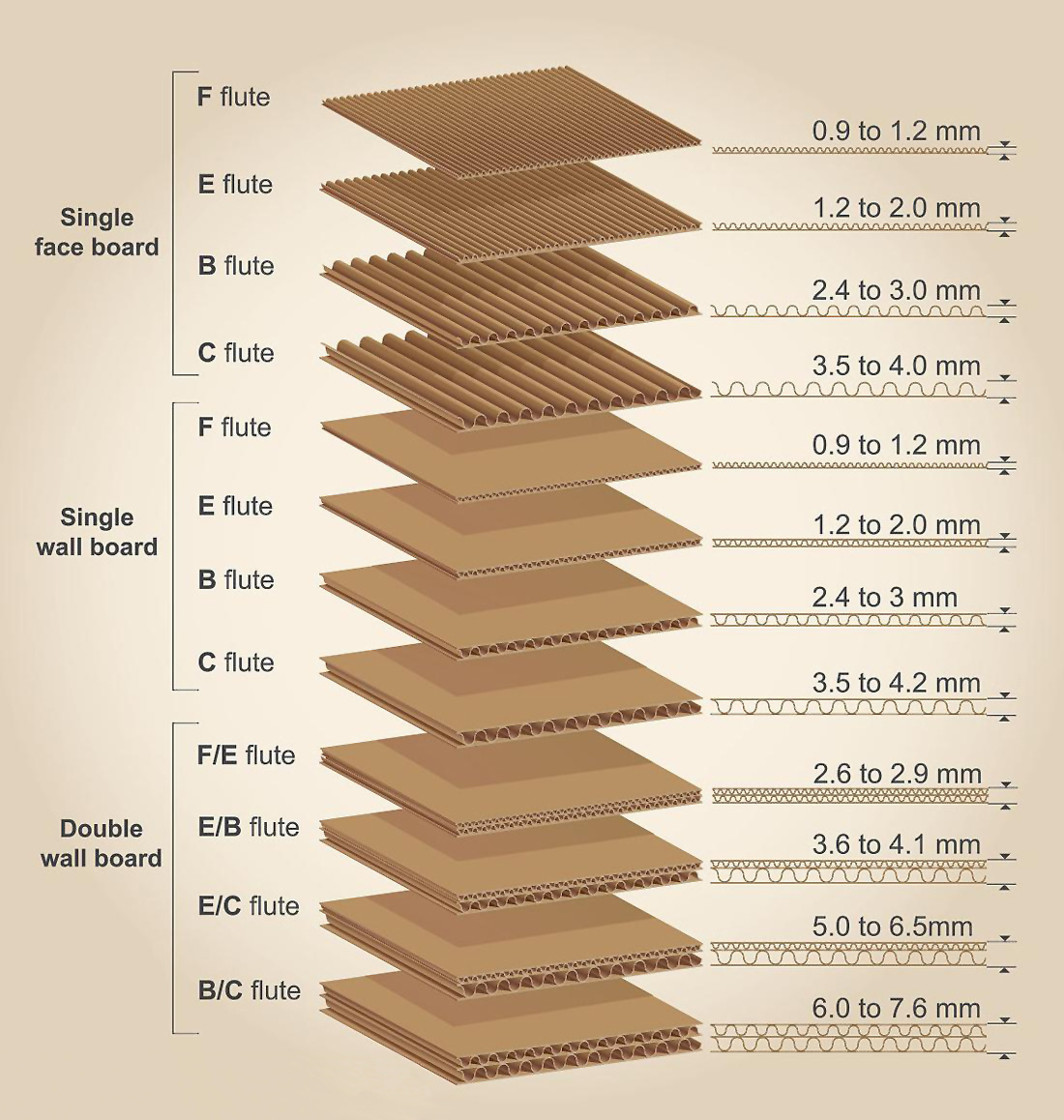

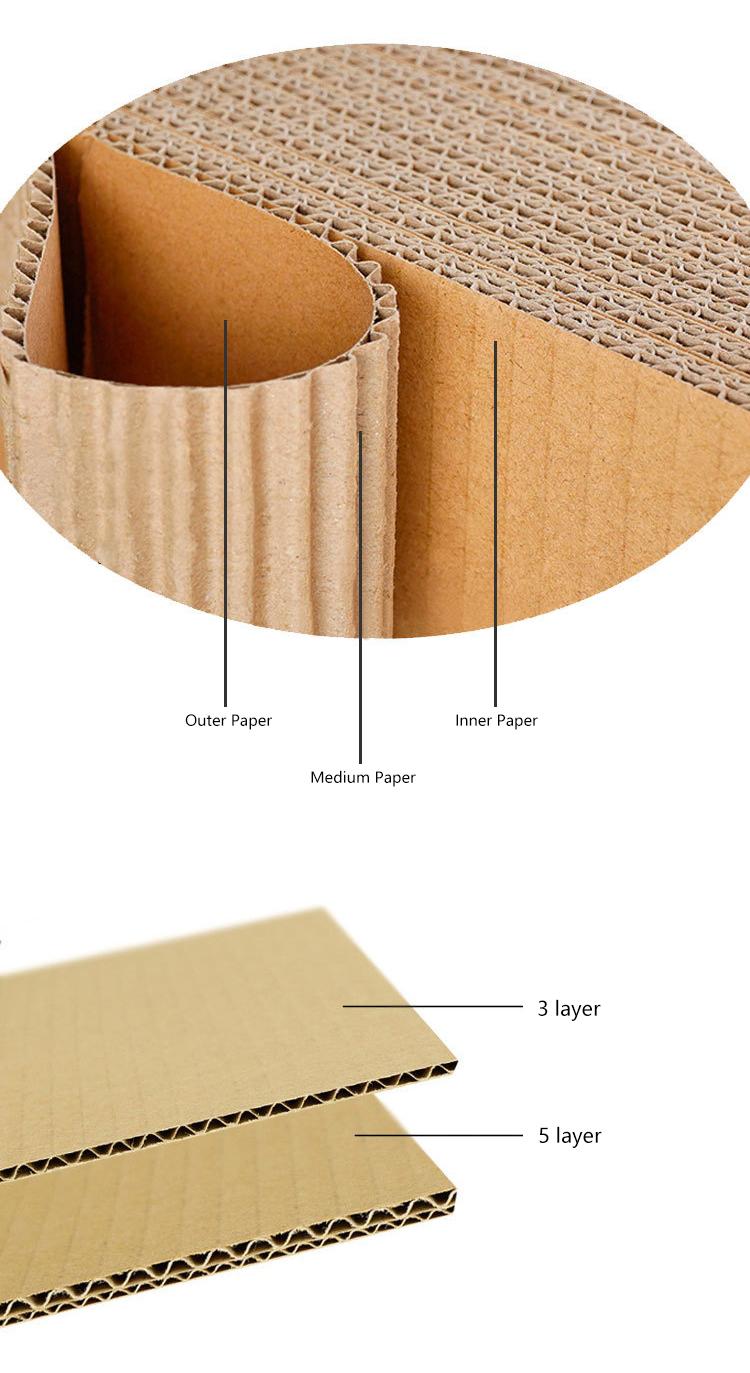

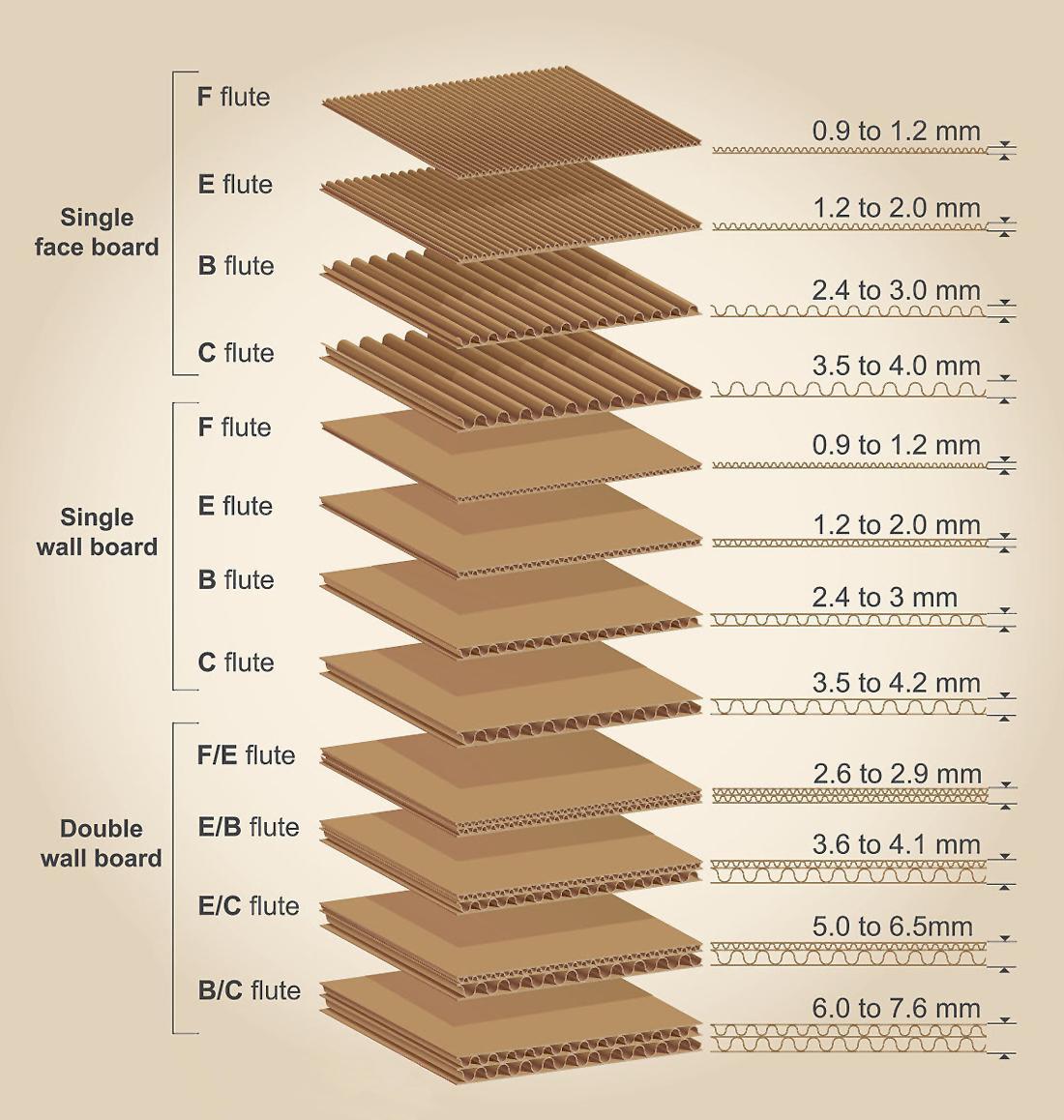

Due to the small size of the box, the corrugated material is E flute. The selection of materials can be based on the weight, size and fragility of the product. The material is strong corrugated paperboard in 3 ply/5 ply, to fit different weight and size of gift product.

Basic Info.

| Product Name | Small Corrugated Box | Surface Handling | Glossy lamination, Matte lamination, Spot UV, Gold Stamping |

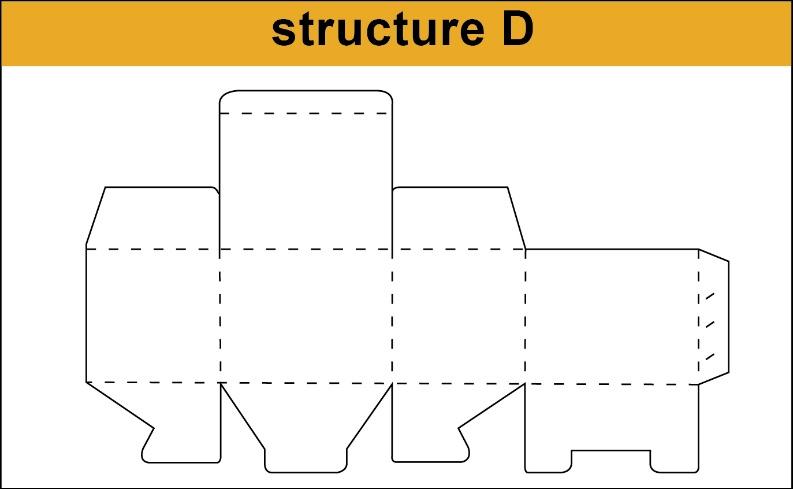

| Box Style | Structure D | Logo Printing | Customized Logo |

| Material Structure | White Board + Corrugated Paper + White Board/kraft paper | Origin | Ningbo |

| Flute type | E flute, B flute, C flute, BE flute | Sample | Accept custom samples |

| Shape | Rectangle | Sample Time | 5-8 Working Days |

| Color | CMYK Color, Pantone Color | Production Lead Time | 8-12 working days based on quantity |

| Printing | Offset Printing | Transport Package | Strong 5 ply Corrugated Carton |

| Type | Single Printing Box | MOQ | 2000PCS |

Detailed Images

We have a professional team to check the structure and printing quality of the box. The Structural designer will adjust the design and cutter mould according to the different materials.

Please communicate and negotiate with the salesperson about the selection of paper materials and printing methods.

Material Structure and Application

The functions of the corrugated cardboard bonded with different corrugated shapes are also different. Even when the same outer paper and inner paper are used, the corrugated board's performance varies because of the varied corrugated shape.

The common types of single corrugated are E flute, B flute and C flute.

The commonly used double wall corrugated combination includes EE flute, BE flute and BC flute.

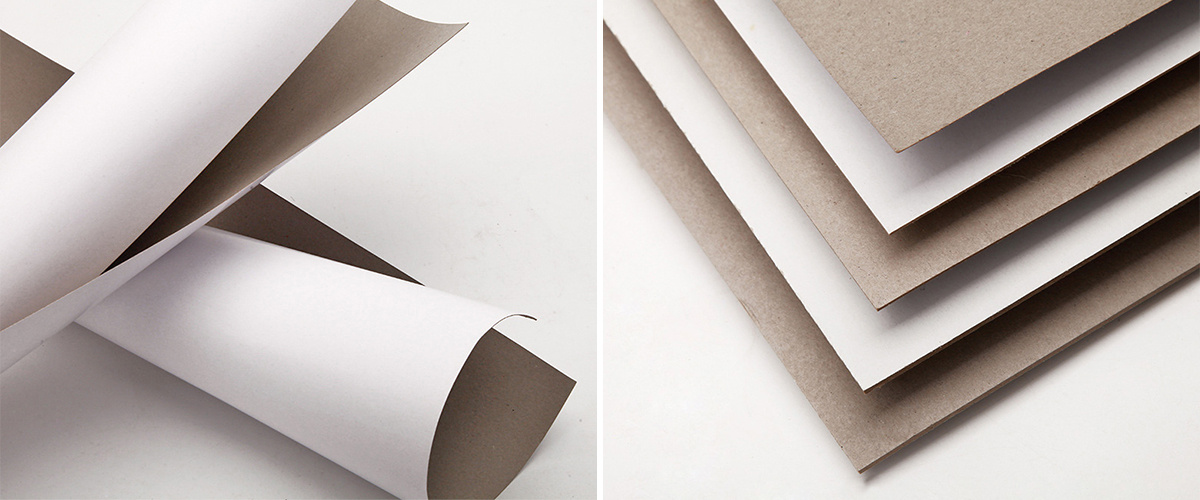

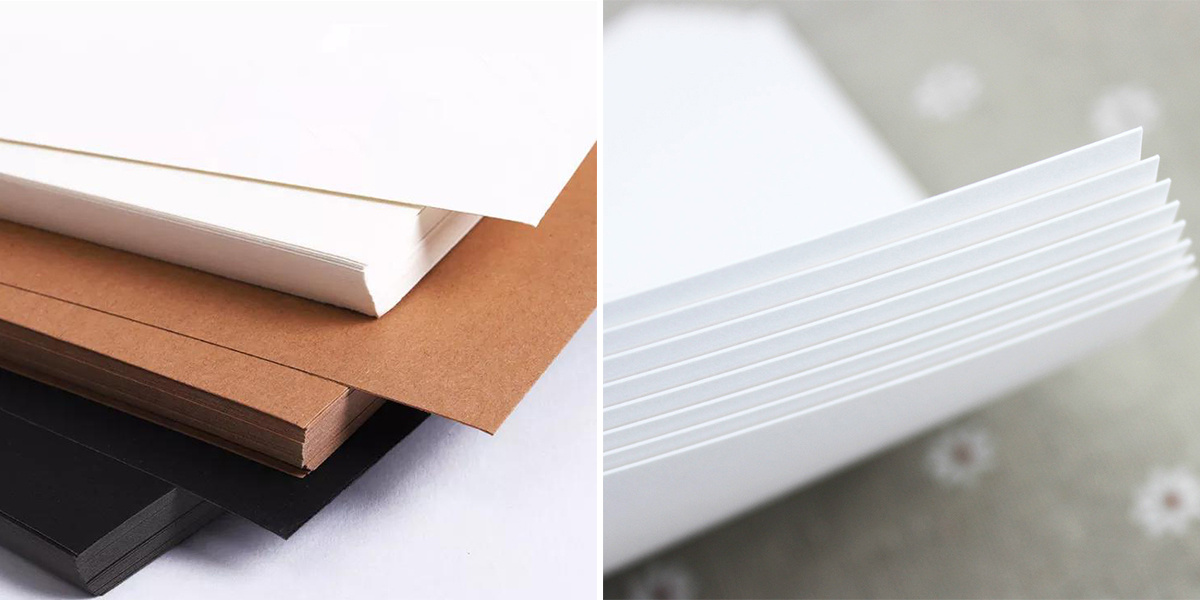

Outer paper material: coated duplex board.

Outer paper material: white card paper, black card paper, kraft paper.

Outer paper material: white card paper, black card paper, kraft paper.

Structural drawing of corrugated cardboard.

Thickness reference of corrugated cardboard.

Packaging Applications

Box Type and Finish Surface

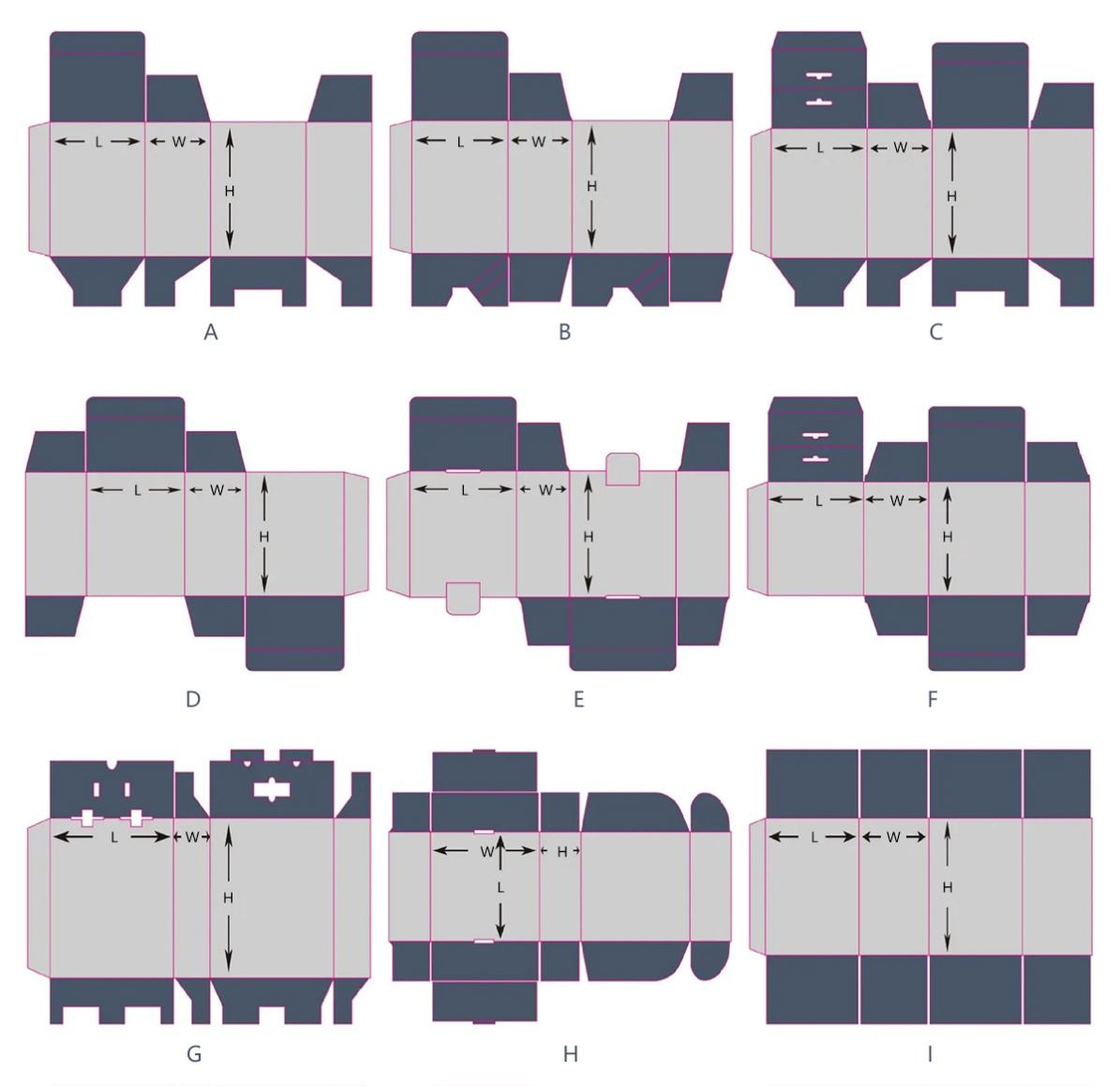

The box type as follow

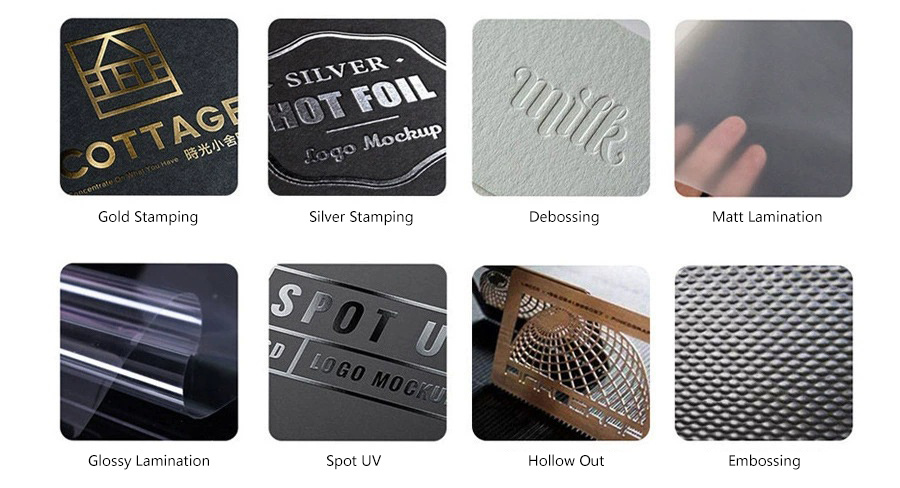

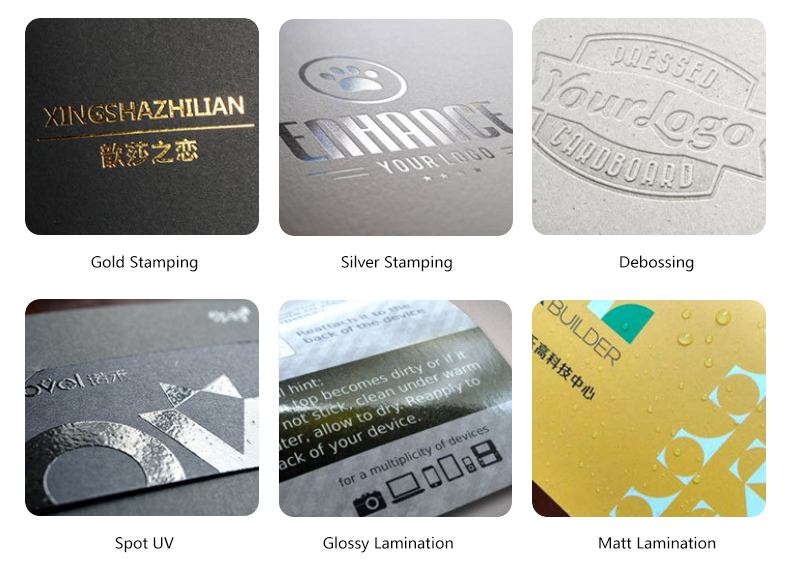

Surface treatment process

Foil Stamping

Foil stamping materials come in a variety of colors, including gold, silver, laser gold, laser silver, black, red, and green, among others.

Lamination

Lamination process refers to using a film covering machine to cover the surface of printed matter with a layer of transparent plastic film.

Debossing

Concave and convex embossing is to use the greater pressure of the relief printing machine to roll the local patterns or characters on the printed semi-finished products into distinct concave and convex, three-dimensional images and characters.

Spot UV

Through UV drying and curing, the ink is bright and special, especially for trademarks, logos and local printing content.

Common Surface Treatment as Follows

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

The functions of the corrugated cardboard bonded with different corrugated shapes are also different. Even when the same outer paper and inner paper are used, the corrugated board’s performance varies because of the varied corrugated shape.

The common types of single corrugated are E flute, B flute and C flute.

The commonly used double wall corrugated combination includes EE flute, BE flute and BC flute.

Outer paper material: coated duplex board.

Outer paper material: white card paper, black card paper, kraft paper.

Outer paper material: art paper.

Structural drawing of corrugated cardboard.

Thickness reference of corrugated cardboard.

Packaging Applications

The box type as follow

Surface treatment process

Foil Stamping

Foil stamping materials come in a variety of colors, including gold, silver, laser gold, laser silver, black, red, and green, among others.

Lamination

Lamination process refers to using a film covering machine to cover the surface of printed matter with a layer of transparent plastic film.

Debossing

Concave and convex embossing is to use the greater pressure of the relief printing machine to roll the local patterns or characters on the printed semi-finished products into distinct concave and convex, three-dimensional images and characters.

Spot UV

Through UV drying and curing, the ink is bright and special, especially for trademarks, logos and local printing content.

Common Surface Treatment as Follows